Address

Unit 6a, Wakefield Business Centre

Denby Dale Road

Denby Dale Road

Wakefield

Yorkshire

WF2 7AZ

England UK

Opening Hours

Today

08:30-17:15

View All Hours

Sunday

Closed

Monday

08:30-17:15

Tuesday

08:30-17:15

Wednesday

08:30-17:15

Thursday

08:30-17:15

Friday

08:30-17:15

Saturday

Closed

About Dural UK

Dural UK specialise in producing hardware for the perfect finish for all types of flooring.

We provide complete solutions for all aspects of flooring including profiles for resin flooring, stone carpets, parquet, laminate, carpeted and tiled floors. Our product range includes Movement Joints, CI+ Anti-Crack Matting, Resin Flooring Profiles, Stair Edgings and Wetroom Linear Drainage Solutions. Whether you are an Architect, Designer, Flooring Contractor or an Installer, we are your one-stop-shop for all your flooring requirements, from our high quality flooring accessories to our highly competent support to guide you through your flooring project.

- Specialise in a comprehensive range of products providing the perfect finish for all types of flooring.

- One-stop-shop for Architects, Designers, Flooring Contractors and Installers.

- Established over 30 years, we offer experience and excellent product knowledge.

- Highly competent advice and support, no matter how complex the application.

Movement Joints

Dural UK produce bespoke movement joints for hard flooring, natural stone and slate. We specialise in colour matching our joints to the grout or the floor finish creating a stylish designer look and a seamless finish. Our Joints are designed and manufactured to exceed the requirements of BS 5385 and are part of our wide range of trims and accessories for flooring.

Dural’s Movement Joints have been specified on many prestigious projects throughout the UK, including retail, commercial, transport, education, hotels, sport & leisure, prisons and even the Olympic Village at London 2012. Major car brands including Ford, Audi, Mercedes and Volkswagon to name a few have used our Movement Joints because they create a high class and seamless finish, which add to the aesthetics . They are also used in the workshop areas because they are durable and have the ability to handle a wide range of loadings.

All CMJ movement joints are designed and manufactured to exceed the requirements of BS 5385 and can be used with Slate, Natural Stone and Ceramic tiled floors.

Not only can our CMJ movement joints cope with heavy stresses and distribute them evenly between the foundation and floor covering, they can also prevent conduction of noise from footfall and other bodies. Even floors subject to heavy stresses remain in better condition for longer when our movement joints are specified.

CI+ Anti-Crack Matting

CI+ Matting from Dural UK serves to make it easier to install floors floors of all kinds, even on difficult surfaces like old screed or wood, and they also protect the new floor covering from moisture seeping from below as well as preventing stretching or cracks.

The mats are made of yellow polythene with a grid of texturing nodules and a supporting polypropylene fleece layer on the back. This combination means the matting is resistant to most chemicals.

Edge Profiling for Resin Floors

Dural UK provides a comprehensive range of products for you to create perfect resin flooring. Our quality, design and functionality of our range of Resin Edge Profiling products gives you confidence that you will achieve impressive results every time.

Our range of Capping Profiles include Edging Profiles (metal and PVC) and Cove Capping (metal and PVC). These products provide delicate detailing and will help your project to create beautiful, seamless flooring for your clients.

We provide complete solutions for all aspects of flooring including profiles for resin flooring, stone carpets, parquet, laminate, carpeted and tiled floors. Our product range includes Movement Joints, CI+ Anti-Crack Matting, Resin Flooring Profiles, Stair Edgings and Wetroom Linear Drainage Solutions. Whether you are an Architect, Designer, Flooring Contractor or an Installer, we are your one-stop-shop for all your flooring requirements, from our high quality flooring accessories to our highly competent support to guide you through your flooring project.

- Specialise in a comprehensive range of products providing the perfect finish for all types of flooring.

- One-stop-shop for Architects, Designers, Flooring Contractors and Installers.

- Established over 30 years, we offer experience and excellent product knowledge.

- Highly competent advice and support, no matter how complex the application.

Movement Joints

Dural UK produce bespoke movement joints for hard flooring, natural stone and slate. We specialise in colour matching our joints to the grout or the floor finish creating a stylish designer look and a seamless finish. Our Joints are designed and manufactured to exceed the requirements of BS 5385 and are part of our wide range of trims and accessories for flooring.

Dural’s Movement Joints have been specified on many prestigious projects throughout the UK, including retail, commercial, transport, education, hotels, sport & leisure, prisons and even the Olympic Village at London 2012. Major car brands including Ford, Audi, Mercedes and Volkswagon to name a few have used our Movement Joints because they create a high class and seamless finish, which add to the aesthetics . They are also used in the workshop areas because they are durable and have the ability to handle a wide range of loadings.

All CMJ movement joints are designed and manufactured to exceed the requirements of BS 5385 and can be used with Slate, Natural Stone and Ceramic tiled floors.

Not only can our CMJ movement joints cope with heavy stresses and distribute them evenly between the foundation and floor covering, they can also prevent conduction of noise from footfall and other bodies. Even floors subject to heavy stresses remain in better condition for longer when our movement joints are specified.

CI+ Anti-Crack Matting

CI+ Matting from Dural UK serves to make it easier to install floors floors of all kinds, even on difficult surfaces like old screed or wood, and they also protect the new floor covering from moisture seeping from below as well as preventing stretching or cracks.

The mats are made of yellow polythene with a grid of texturing nodules and a supporting polypropylene fleece layer on the back. This combination means the matting is resistant to most chemicals.

Edge Profiling for Resin Floors

Dural UK provides a comprehensive range of products for you to create perfect resin flooring. Our quality, design and functionality of our range of Resin Edge Profiling products gives you confidence that you will achieve impressive results every time.

Our range of Capping Profiles include Edging Profiles (metal and PVC) and Cove Capping (metal and PVC). These products provide delicate detailing and will help your project to create beautiful, seamless flooring for your clients.

Gallery

Videos

News

Introduction

In recent years, resin bound surfacing has transformed housing developments across the UK. Gone are the days of using block paving or concrete to create functional driveways, paths and garden areas; now homeowners want to create an outside space which looks beautiful, is easy to maintain and stands the test of time.

What is resin bound surfacing?

Resin bound surfacing is where resin and natural stone are mixed and then laid onto a prepared surface. The material is then trowelled down to a smooth finish. The depth of a resin bound paving surface should be roughly between 12 and 24mm depending on the application and the size and type of stone used in the process.

Resin bound surfacing is often mistaken with resin bonded surfacing (it is easy to see why with very similar sounding names!). Resin bonded surfacing is where natural stone is laid onto a pre-spread resin base. Once this process is complete a film of resin is then applied to the surface. Resin bonded surfacing has more of a textured look and often has the appearance of loose gravel. A typical depth of a Resin bonded surface is around 6 to 8mm.

Why use resin bound surfacing compared to other surface materials?

Homeowners and clients alike appreciate the benefits of a resin bound surface. Not only do they get a visually attractive driveway or path giving their property ‘kerb appeal’, but it also brings many practical qualities also. The resin bound surface requires very little maintenance and the physical properties with the natural aggregate and resin form to create an extremely hard-wearing surface.

Compared to other surfacing materials, resin bound surfacing has clear benefits. Block paving, although can look clean and quite pleasing to the eye when first laid, is prone to degredation over time. Even after a year or two the colour fades and as the blocks are fixed onto a simple substrate with no movement considered, they are prone to cracks and displacement. Another headache for homeowners with block paving is weed growth within the surface joints.

As resin bound surfacing is constructed of many particles of stone aggregate mixed with resin, it is virtually impossible for cracks or displacement. The durability of the surface means it can also withstand heavy loadings e.g. cars, plus the aesthetics is guaranteed for many years from colour discolouration and UV degredation.

Another advantage of resin bound surfacing compared with block paving is the time saving benefit during installation. This particular factor refers to refurbishment projects, where it is possible to lay the resin bound material directly over existing concrete driveways (after the concrete has been cleaned and primed). This saves time and ultimately labour costs, as the original concrete substrate needs little work to prepare.

Another popular surfacing material is concrete. Concrete is generally of a robust and hard-wearing structure, and should give homeowners many years of func

In recent years, resin bound surfacing has transformed housing developments across the UK. Gone are the days of using block paving or concrete to create functional driveways, paths and garden areas; now homeowners want to create an outside space which looks beautiful, is easy to maintain and stands the test of time.

What is resin bound surfacing?

Resin bound surfacing is where resin and natural stone are mixed and then laid onto a prepared surface. The material is then trowelled down to a smooth finish. The depth of a resin bound paving surface should be roughly between 12 and 24mm depending on the application and the size and type of stone used in the process.

Resin bound surfacing is often mistaken with resin bonded surfacing (it is easy to see why with very similar sounding names!). Resin bonded surfacing is where natural stone is laid onto a pre-spread resin base. Once this process is complete a film of resin is then applied to the surface. Resin bonded surfacing has more of a textured look and often has the appearance of loose gravel. A typical depth of a Resin bonded surface is around 6 to 8mm.

Why use resin bound surfacing compared to other surface materials?

Homeowners and clients alike appreciate the benefits of a resin bound surface. Not only do they get a visually attractive driveway or path giving their property ‘kerb appeal’, but it also brings many practical qualities also. The resin bound surface requires very little maintenance and the physical properties with the natural aggregate and resin form to create an extremely hard-wearing surface.

Compared to other surfacing materials, resin bound surfacing has clear benefits. Block paving, although can look clean and quite pleasing to the eye when first laid, is prone to degredation over time. Even after a year or two the colour fades and as the blocks are fixed onto a simple substrate with no movement considered, they are prone to cracks and displacement. Another headache for homeowners with block paving is weed growth within the surface joints.

As resin bound surfacing is constructed of many particles of stone aggregate mixed with resin, it is virtually impossible for cracks or displacement. The durability of the surface means it can also withstand heavy loadings e.g. cars, plus the aesthetics is guaranteed for many years from colour discolouration and UV degredation.

Another advantage of resin bound surfacing compared with block paving is the time saving benefit during installation. This particular factor refers to refurbishment projects, where it is possible to lay the resin bound material directly over existing concrete driveways (after the concrete has been cleaned and primed). This saves time and ultimately labour costs, as the original concrete substrate needs little work to prepare.

Another popular surfacing material is concrete. Concrete is generally of a robust and hard-wearing structure, and should give homeowners many years of func

More and more home owners are choosing to install underfloor heating systems in recent years. Their popularity has surged as they provide a cost-effective, comfortable, unobtrusive heating solution for millions of homes. However, if underfloor heating systems are installed and there is no adequate movement protection for the tiled surface, then the expansions and contractions caused by the heating systems will almost certainly result in cracked tiling surfaces.

Dural UK’s new and innovative Micro Joint Infill is the solution for this problem, and provides discreet stress protection for tiles and natural stone on heated floors.

Underfloor heating systems and the potential problems they bring

Over the past five years, there has been a sharp rise in popularity in underfloor heating systems. Industry experts estimate that the market has nearly doubled annually since 2014. It is easy to understand the reasons behind this increase in popularity.

For homeowners, by installing underfloor heating systems they will get high comfort levels in their homes and low running costs (upto 30% greater energy efficiency compared to traditional heating methods). For Architects and Designers, incorporating underfloor heating systems into residential build projects enables them to achieve modern energy effiency regulations, reduce the carbon footprint of buildings, and facilitates more contemporary design concepts i.e. no obtrusive radiators or air vents.

Underfloor heating systems can often prove to be problematic for tiled flooring installations. The main problem with underfloor heating systems is the resultant movement, or thermal expansion, it causes in the subfloor. This movement is then transferred into the surface layer, or the tiled flooring. These tensions and stresses are too great for the tiled flooring to cope with. There are two consequences to this – one is the tiles could ‘tent’ or ‘pop’ off the floor resulting in loose tiles; and the other is hairline cracks could appear in the tiled surface.

This is very common in large format tiles, which are experiencing huge growth levels and are expected to be a big flooring trend throughout 2016. Large format tiles have a higher coefficient of thermal expansion, so for a given temperature rise they will grow proportionally more than smaller tiles. If this rate of expansion isn’t accommodated for with some form of movement protection, the tile material will crack or ‘tent’ under the pressure.

Benefits of Micro Joint Infill for tiles on underfloor heating systems

UK Building Regulations BS5385 require that expanses of hard flooring as a finished surface material have to conform to various functional and aesthetic standards. To achieve compliance, it is essential for 40sqm or above flooring installations to have some sort of movement protection in place.

Dural’s Micro Joint Infill has been specifically developed for tiled flooring installations which are laid over underfloor heating systems,

Dural UK’s new and innovative Micro Joint Infill is the solution for this problem, and provides discreet stress protection for tiles and natural stone on heated floors.

Underfloor heating systems and the potential problems they bring

Over the past five years, there has been a sharp rise in popularity in underfloor heating systems. Industry experts estimate that the market has nearly doubled annually since 2014. It is easy to understand the reasons behind this increase in popularity.

For homeowners, by installing underfloor heating systems they will get high comfort levels in their homes and low running costs (upto 30% greater energy efficiency compared to traditional heating methods). For Architects and Designers, incorporating underfloor heating systems into residential build projects enables them to achieve modern energy effiency regulations, reduce the carbon footprint of buildings, and facilitates more contemporary design concepts i.e. no obtrusive radiators or air vents.

Underfloor heating systems can often prove to be problematic for tiled flooring installations. The main problem with underfloor heating systems is the resultant movement, or thermal expansion, it causes in the subfloor. This movement is then transferred into the surface layer, or the tiled flooring. These tensions and stresses are too great for the tiled flooring to cope with. There are two consequences to this – one is the tiles could ‘tent’ or ‘pop’ off the floor resulting in loose tiles; and the other is hairline cracks could appear in the tiled surface.

This is very common in large format tiles, which are experiencing huge growth levels and are expected to be a big flooring trend throughout 2016. Large format tiles have a higher coefficient of thermal expansion, so for a given temperature rise they will grow proportionally more than smaller tiles. If this rate of expansion isn’t accommodated for with some form of movement protection, the tile material will crack or ‘tent’ under the pressure.

Benefits of Micro Joint Infill for tiles on underfloor heating systems

UK Building Regulations BS5385 require that expanses of hard flooring as a finished surface material have to conform to various functional and aesthetic standards. To achieve compliance, it is essential for 40sqm or above flooring installations to have some sort of movement protection in place.

Dural’s Micro Joint Infill has been specifically developed for tiled flooring installations which are laid over underfloor heating systems,

Subfloor movement is a crucial consideration for tiled flooring installations. In almost all build projects, tiled flooring expands and contracts at different rates to that of the subfloor beneath it.

To accommodate this, it is essential for flooring installations to have movement protection in place to absorb the movement and protect the surface tiles. This protection comes in the form of movement joints.

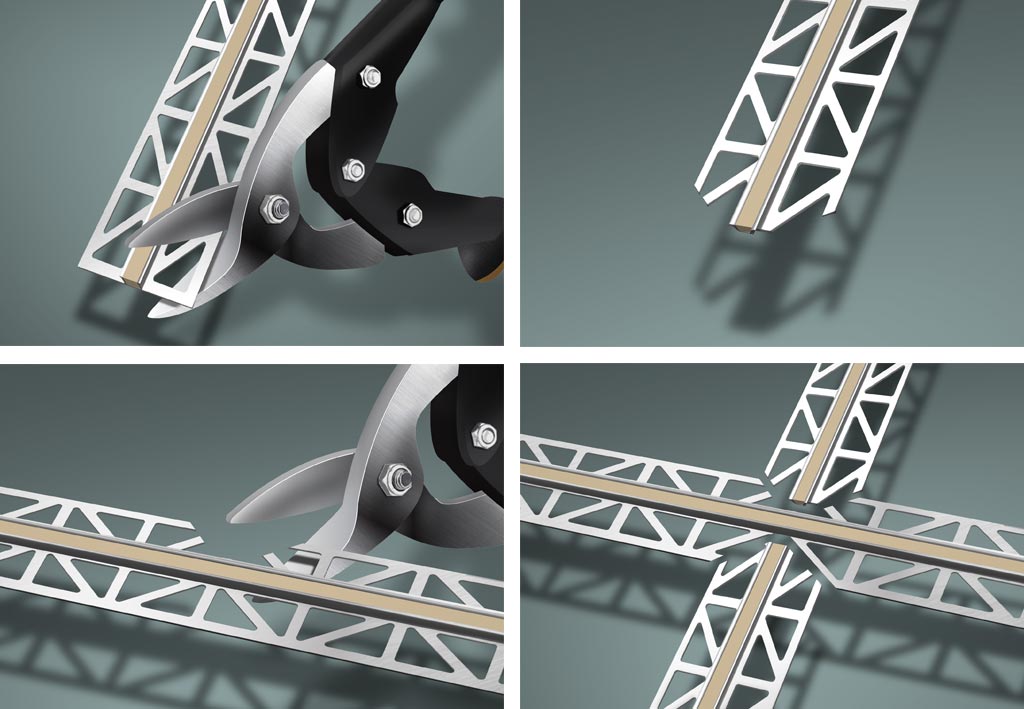

By installing movement joints into tiled flooring installations, these will effectively absorb any heavey stresses and vertical movement from passing to the surface tiles. However Installers face a common problem where expansion joints need to cross over each other. By cutting and shaping with tin snips they are able to produce crossing junctions, but this method is technically demanding and time consuming.

As a result, Dural UK has introduced pre-formed junctions as a new and faster way of creating these junctions, compared to traditional methods, in the form of their new Cross Joints.

Preparing cross joints – the old, slow way

UK Building Regulations BS5385 state that expanses of hard flooring as a finished surface material have to conform to various functional and aesthetic standards. Commercial and industrial buildings which have large expanses of hard flooring as a finished surface material have to ensure compliance.

Architects and Designers are often faced with the problem where the subfloor movement joints intersect with each other, even in early design concepts where it is considered there is generally a little more control over the structural design. As the surface expansion joints have to be placed directly above the subfloor movement joints, it means these joints have no other option but to cross each other.

Creating a four-way junction with movement joints is technically demanding for installers, as well as costly and time consuming. Not only that but the level of movement protection offered by the cross junction may be compromised by the quality of the installer, as they have to cut the joints in a way to successfully integrate together. The movement joints are liable to warping and deterioration where they are cut as the integrity of the joints are compromised.

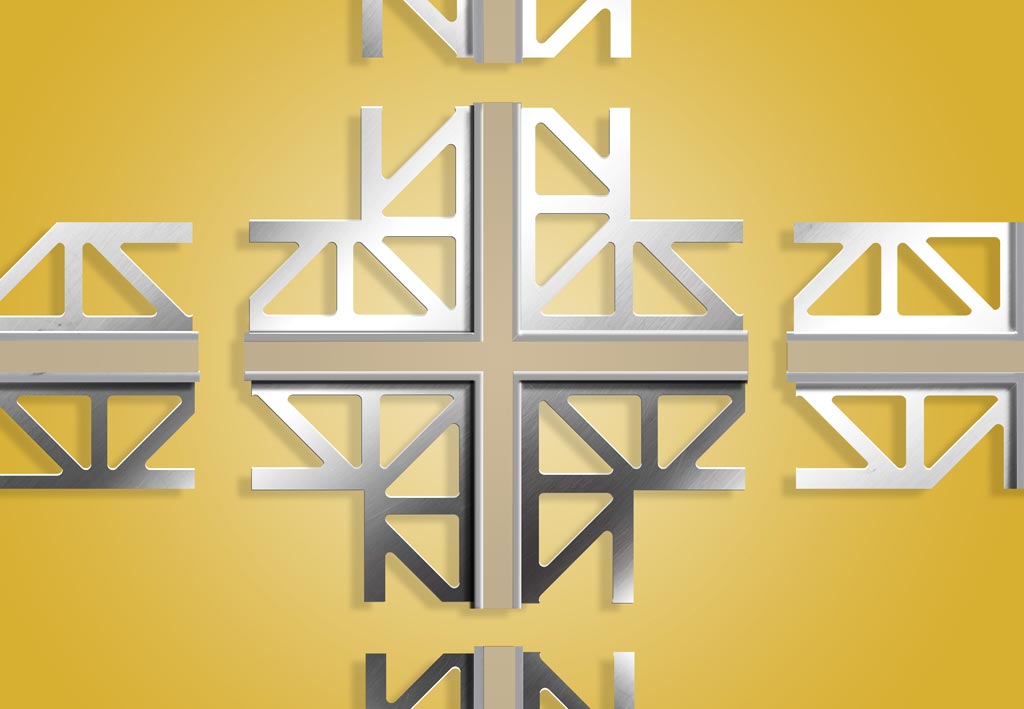

Preparing cross joints – the new, faster way with Dural’s Cross Joints

Dural’s Cross Joints are a new, innovative solution for creating a four-way junction. They are pre-formed joints which are simply placed over the junction in the subfloor and in-line with the surface movement joints. Anchored in the adhesive bed, the Cross Joints are then installed using the same procedure that standard movement joints are fitted with.

The Cross Joints allow movement accommodation in all directions simultaneously. They absorb the stresses created by vertical movement from expansion and contraction across the four surface areas at the junction. This means the stresses and subfloor movement are not transferred into the surface tiles, preventing cracks, loose t

To accommodate this, it is essential for flooring installations to have movement protection in place to absorb the movement and protect the surface tiles. This protection comes in the form of movement joints.

By installing movement joints into tiled flooring installations, these will effectively absorb any heavey stresses and vertical movement from passing to the surface tiles. However Installers face a common problem where expansion joints need to cross over each other. By cutting and shaping with tin snips they are able to produce crossing junctions, but this method is technically demanding and time consuming.

As a result, Dural UK has introduced pre-formed junctions as a new and faster way of creating these junctions, compared to traditional methods, in the form of their new Cross Joints.

Preparing cross joints – the old, slow way

UK Building Regulations BS5385 state that expanses of hard flooring as a finished surface material have to conform to various functional and aesthetic standards. Commercial and industrial buildings which have large expanses of hard flooring as a finished surface material have to ensure compliance.

Architects and Designers are often faced with the problem where the subfloor movement joints intersect with each other, even in early design concepts where it is considered there is generally a little more control over the structural design. As the surface expansion joints have to be placed directly above the subfloor movement joints, it means these joints have no other option but to cross each other.

Creating a four-way junction with movement joints is technically demanding for installers, as well as costly and time consuming. Not only that but the level of movement protection offered by the cross junction may be compromised by the quality of the installer, as they have to cut the joints in a way to successfully integrate together. The movement joints are liable to warping and deterioration where they are cut as the integrity of the joints are compromised.

Preparing cross joints – the new, faster way with Dural’s Cross Joints

Dural’s Cross Joints are a new, innovative solution for creating a four-way junction. They are pre-formed joints which are simply placed over the junction in the subfloor and in-line with the surface movement joints. Anchored in the adhesive bed, the Cross Joints are then installed using the same procedure that standard movement joints are fitted with.

The Cross Joints allow movement accommodation in all directions simultaneously. They absorb the stresses created by vertical movement from expansion and contraction across the four surface areas at the junction. This means the stresses and subfloor movement are not transferred into the surface tiles, preventing cracks, loose t

UK

UK Ireland

Ireland Scotland

Scotland London

London