Address

137 Hankinson Road

Bournemouth

South West

BH9 1HR

About Lasermet Ltd

About Lasermet

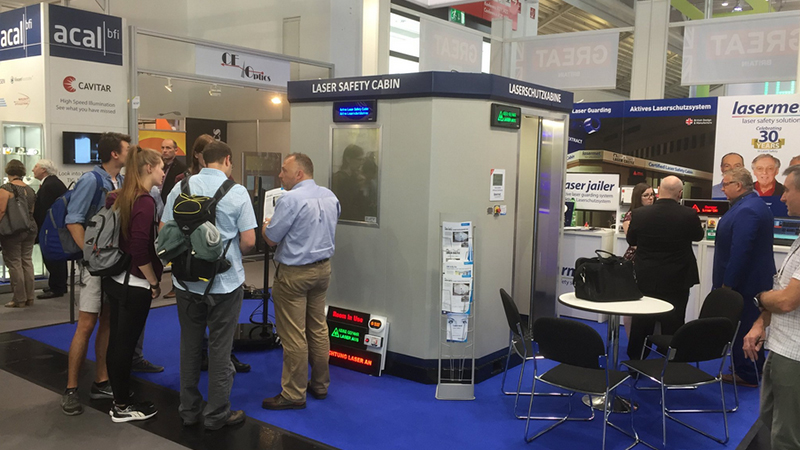

Lasermet is the British designer, manufacturer and installer of a laser safety equipment and systems. Lasermet covers everything from laser safety consultancy to the manufacture of high quality LED signs, and all of the laser safety requirements of hospital theatres.

This includes laser safety interlock controllers, low voltage LED signs, audible warning equipment, laser blocking roller blinds and laser blocking curtains.

Lasermet also manufactures laser blocking screens for use during the servicing of lasers in manufacturing or research facilities, universities and other educational institutions.

For electrical contractors Lasermet produces the thin profile Slim Jim LED Sign. At just 11mm deep this LED sign connects directly to 230V AC (no transformer required). It is contractor friendly as it connects straight onto electrical back boxes and can have and wording or message illuminated within the space of the display.

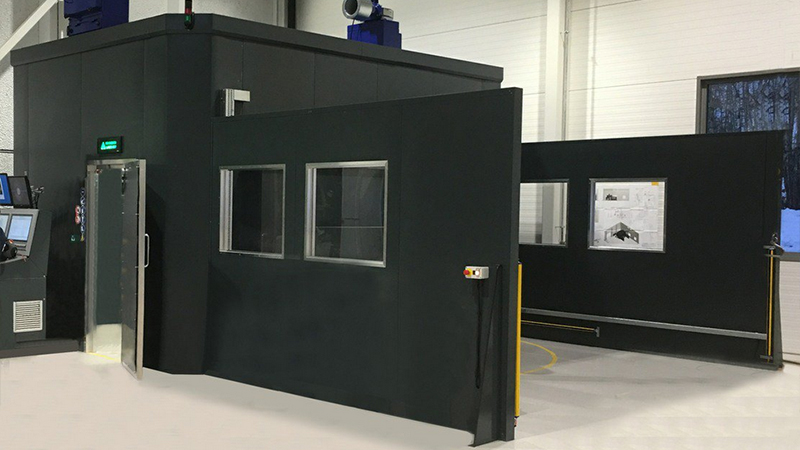

Laser Castle is the name given to the range of complete modular laser safety enclosures produced by Lasermet. These provide all of the relevant laser safety systems in the manufacturing industry where high powered lasers are used for welding or cutting often using robots.

Lasermet is the British designer, manufacturer and installer of a laser safety equipment and systems. Lasermet covers everything from laser safety consultancy to the manufacture of high quality LED signs, and all of the laser safety requirements of hospital theatres.

This includes laser safety interlock controllers, low voltage LED signs, audible warning equipment, laser blocking roller blinds and laser blocking curtains.

Lasermet also manufactures laser blocking screens for use during the servicing of lasers in manufacturing or research facilities, universities and other educational institutions.

For electrical contractors Lasermet produces the thin profile Slim Jim LED Sign. At just 11mm deep this LED sign connects directly to 230V AC (no transformer required). It is contractor friendly as it connects straight onto electrical back boxes and can have and wording or message illuminated within the space of the display.

Laser Castle is the name given to the range of complete modular laser safety enclosures produced by Lasermet. These provide all of the relevant laser safety systems in the manufacturing industry where high powered lasers are used for welding or cutting often using robots.

- Laser safety consultants

- LED Signs

- Audible warning systems

- Roller blinds – laser blocking

- Curtains – laser blocking

- Laser safety cabins

- Hospital theatres – laser safety

- Interlock control for lasers

- Interlock control for X-rays

- Laser Warning Labels

- Laser safety eyewear

Gallery

Videos

News

Numerous orders were taken for their Laser welding containment systems at the show. This included orders for the Laser Castle Lite – the low-cost modular build cabin for hand held laser welders, and the Dolphin – the curtained laser welding enclosure. Orders were taken for the Alf Laser Welding Helmet – which has become a high-demand safety helmet in the hand-held laser welding industry. Everyone who saw it at the show said it looked really cool.

The Alf laser welding helmet is an interlocked laser welding helmet specifically designed to work with laser light welding applications. The UV and laser wavelength filter window provides protection from laser radiation whilst still enabling sufficient light through to be able to weld without having to remove the mask to see the complete workpiece. With a full 60° angle of view, the Alf is connected to the laser safety interlock controller attached to the laser welding enclosure. To enable the laser to be enabled, the door to the enclosure must be closed and the helmet must be worn by the user and the visor must be in the down position. Only then will the laser be enabled. This ensures that the helmet is used correctly and that the laser welder has his or her eyes and face protected.

The laser interlock controller is held on a bracket within the enclosure. There are two options of the low-cost, self-assembly containment systems. The first is the Laser Castle Lite – a modular laser safety cabin measuring 10 x 10ft x 8ft tall (3 x 3m x 2.4m tall). This unit is easily assembled and locked together within a couple of hours. It can be expanded by simply adding more modules and can be easily moved to alternative locations.

The second option is the Dolphin curtained laser welding enclosure (or pod) which is an 8ft (2.4m) cubic steel frame with specially designed laser blocking curtains held around all four sides. One of the sides is used as a door which can be closed and interlocked. Once inside, the Alf laser welding helmet is connected to the interlock controller. (Two helmets can be used on the standard system if required). The interlock control system then connects to the laser so that when the helmet is worn AND the visor is down, the laser is enabled. Opening the door, lifting the Alf visor, or removing the Alf helmet will all disable the laser.

For further details on the Alf helmet, the Laser Castle Lite or the Dolphin curtained laser welding pod visit lasermet.com.

The Alf laser welding helmet is an interlocked laser welding helmet specifically designed to work with laser light welding applications. The UV and laser wavelength filter window provides protection from laser radiation whilst still enabling sufficient light through to be able to weld without having to remove the mask to see the complete workpiece. With a full 60° angle of view, the Alf is connected to the laser safety interlock controller attached to the laser welding enclosure. To enable the laser to be enabled, the door to the enclosure must be closed and the helmet must be worn by the user and the visor must be in the down position. Only then will the laser be enabled. This ensures that the helmet is used correctly and that the laser welder has his or her eyes and face protected.

The laser interlock controller is held on a bracket within the enclosure. There are two options of the low-cost, self-assembly containment systems. The first is the Laser Castle Lite – a modular laser safety cabin measuring 10 x 10ft x 8ft tall (3 x 3m x 2.4m tall). This unit is easily assembled and locked together within a couple of hours. It can be expanded by simply adding more modules and can be easily moved to alternative locations.

The second option is the Dolphin curtained laser welding enclosure (or pod) which is an 8ft (2.4m) cubic steel frame with specially designed laser blocking curtains held around all four sides. One of the sides is used as a door which can be closed and interlocked. Once inside, the Alf laser welding helmet is connected to the interlock controller. (Two helmets can be used on the standard system if required). The interlock control system then connects to the laser so that when the helmet is worn AND the visor is down, the laser is enabled. Opening the door, lifting the Alf visor, or removing the Alf helmet will all disable the laser.

For further details on the Alf helmet, the Laser Castle Lite or the Dolphin curtained laser welding pod visit lasermet.com.

Every hospital in England is being asked to create priority assessment pods for patients with suspected coronavirus, the NHS has said.

To help meet the demand for Coronavirus testing, Lasermet has increased production of its modular testing pods, also known as procedure pods or storage pods.

These pods or cabins can be installed in a single day either inside buildings or outside in dedicated areas.

Due to their rapid build and deployment capability, the Coronavirus Testing Pods can be used to check for coronavirus by dedicated virus testing staff.

These covid-19 inspection pods can also be used as virus isolation pods or for treatment, or for cold storage.

They can be installed in areas that may be difficult for conventional portable cabins to be located.

As they are modular buildings, they can be built on site to virtually any size. If they need to be relocated, they can either be moved by forklift or they can be quickly dismantled, moved and rebuilt in a single day.

The specification of the modular cabin or pod can include a range of door sizes, windows, ventilation systems, electronic LED signage, lighting and heating.

They are suitable for daily deep cleaning and are weatherproof for outdoor situations e.g. in car parks.

The pods are highly insulated and can be used for numerous purposes.

They can be thermostatically controlled to keep personnel warm or they can be chilled to low temperatures efficiently for cold room storage applications.

The modular pods can be rapidly resized, rebuilt and recommissioned in a single day. For example, if hospitals require bigger pods, Lasermet can install additional modular panels.

These covid-19 pods are designed for rapid deployment anywhere in the world. They can be shipped in containers as flatpacks and can be built on site by two people.

They are portable and re-deployable; they are clean-room capable; they are suitable for deep cleaning and can be climate controlled for heating or refrigeration. They are weatherproof for outside use and are available now for installation worldwide without cranes or heavy lifting gear.

Contact Lasermet for further details or visit www.lasermet.com/coronaviruspods

To help meet the demand for Coronavirus testing, Lasermet has increased production of its modular testing pods, also known as procedure pods or storage pods.

These pods or cabins can be installed in a single day either inside buildings or outside in dedicated areas.

Due to their rapid build and deployment capability, the Coronavirus Testing Pods can be used to check for coronavirus by dedicated virus testing staff.

These covid-19 inspection pods can also be used as virus isolation pods or for treatment, or for cold storage.

They can be installed in areas that may be difficult for conventional portable cabins to be located.

As they are modular buildings, they can be built on site to virtually any size. If they need to be relocated, they can either be moved by forklift or they can be quickly dismantled, moved and rebuilt in a single day.

The specification of the modular cabin or pod can include a range of door sizes, windows, ventilation systems, electronic LED signage, lighting and heating.

They are suitable for daily deep cleaning and are weatherproof for outdoor situations e.g. in car parks.

The pods are highly insulated and can be used for numerous purposes.

They can be thermostatically controlled to keep personnel warm or they can be chilled to low temperatures efficiently for cold room storage applications.

The modular pods can be rapidly resized, rebuilt and recommissioned in a single day. For example, if hospitals require bigger pods, Lasermet can install additional modular panels.

These covid-19 pods are designed for rapid deployment anywhere in the world. They can be shipped in containers as flatpacks and can be built on site by two people.

They are portable and re-deployable; they are clean-room capable; they are suitable for deep cleaning and can be climate controlled for heating or refrigeration. They are weatherproof for outside use and are available now for installation worldwide without cranes or heavy lifting gear.

Contact Lasermet for further details or visit www.lasermet.com/coronaviruspods

The Falcon Active Speed Door is a high-speed industrial roller shutter door designed for frequent high-speed traffic in manufacturing processes including laser processing applications.

It is ideal for indoor or outdoor installations using rapid incoming and outgoing logistics operations.

The door has a speed range of between 0.6 and 1.8 m/s providing an open/close time of less than 3 seconds.

The Falcon incorporates safety systems which can be application or industry specific. For example, the Falcon can use a PLC bump switch, a safe edge or photocell (connected to the customer’s PLC) to control the door.

Furthermore, the Falcon can be connected to Lasermet’s Laser Interlock Control System for use in laser processing manufacturing installations.

In this case, the interlock only allows the laser to fire when the door is closed. Being a dual-channel controller, the laser system can be wired to satisfy the safety requirements in ISO 13849-1 (Safety of machinery) Performance Level ‘e’.

Optional active laser guarding can be incorporated for very high powered (multi-kW) lasers. This is called Laser Jailer and it is a failsafe laser protection system where the laser is shutdown if the laser beam inadvertently strikes the inside of the door.

Lasermet produce a range of doors for automation systems including guillotine doors, bi-parting motorised single or double doors, turntable doors.

Doors in action can be seen on these Youtube links…

Falcon Active Speed Door https://www.youtube.com/watch?v=Khk0vQgoZ5k

Motorised Double-double doors https://www.youtube.com/watch?v=dpGUkNKOB7s

Turntable doors https://www.youtube.com/watch?v=gXfcs86j50Y

Auto-sliding-door safety demo https://www.youtube.com/watch?v=lQ62n18aYHs

Guillotine doors https://www.youtube.com/watch?v=Nmf_TmGc4Hc

Visit Lasermet industrial doors https://www.lasermet.com/industrial-high-speed-doors.php

See the Falcon Active Speed Door at the MACH 2020 exhibition on stand 17-543

It is ideal for indoor or outdoor installations using rapid incoming and outgoing logistics operations.

The door has a speed range of between 0.6 and 1.8 m/s providing an open/close time of less than 3 seconds.

The Falcon incorporates safety systems which can be application or industry specific. For example, the Falcon can use a PLC bump switch, a safe edge or photocell (connected to the customer’s PLC) to control the door.

Furthermore, the Falcon can be connected to Lasermet’s Laser Interlock Control System for use in laser processing manufacturing installations.

In this case, the interlock only allows the laser to fire when the door is closed. Being a dual-channel controller, the laser system can be wired to satisfy the safety requirements in ISO 13849-1 (Safety of machinery) Performance Level ‘e’.

Optional active laser guarding can be incorporated for very high powered (multi-kW) lasers. This is called Laser Jailer and it is a failsafe laser protection system where the laser is shutdown if the laser beam inadvertently strikes the inside of the door.

Lasermet produce a range of doors for automation systems including guillotine doors, bi-parting motorised single or double doors, turntable doors.

Doors in action can be seen on these Youtube links…

Falcon Active Speed Door https://www.youtube.com/watch?v=Khk0vQgoZ5k

Motorised Double-double doors https://www.youtube.com/watch?v=dpGUkNKOB7s

Turntable doors https://www.youtube.com/watch?v=gXfcs86j50Y

Auto-sliding-door safety demo https://www.youtube.com/watch?v=lQ62n18aYHs

Guillotine doors https://www.youtube.com/watch?v=Nmf_TmGc4Hc

Visit Lasermet industrial doors https://www.lasermet.com/industrial-high-speed-doors.php

See the Falcon Active Speed Door at the MACH 2020 exhibition on stand 17-543

Products & Services

Team

| Name | Role | Telephone | |

|---|---|---|---|

| Simon Last | Sales Manager UK and Ireland | simon.last@lasermet.com | 01202 770740 |

UK

UK Ireland

Ireland Scotland

Scotland London

London