Address

Suite 7 Papyrus Business Parc

Papyrus Road

Papyrus Road

Werrington,

Peterborough

PE4 5BH

United Kingdom

Opening Hours

Today

Closed

View All Hours

Sunday

Closed

Monday

08:00-17:00

Tuesday

08:00-17:00

Wednesday

08:00-17:00

Thursday

08:00-17:00

Friday

08:00-17:00

Saturday

Closed

Other Dates

For out of hours purchasing please visit our on line shop via the web site

About Encasement Ltd

Welcome to Encasement Ltd - the home of preformed pipe boxing, fire sprinkler pipe casings, pipe protection and column casings, together with interior cladding and retail display.

Encasement sustainable building solutions are widely used in countless applications and sectors including social and private house building education, PFI healthcare, leisure, retail, commercial, property development and public buildings. Our range is designed to meet the needs of a broad range of projects requiring pipe boxing, pipe casings, column casing and boiler pipe casings, as well as interior wall cladding, retail interiors & display and external pipe protection solutions.

Products

Versa FR Fire Sprinkler Boxing

Strong, versatile and cost effective

Where flame retardant boxing is required to conceal fire sprinkler installations, Versa FR is the perfect solution, as it is manufactured from Euroclass B standard compliant board.

Versa FR is fabricated from flame retardant FSC© 'Chain of Custody' certified material, which has a white painted finish, giving a joint-less and easy to clean surface to integrate with the interiors of flats and communal areas.

It can be easily cut to length on site and drilled to accommodate fire sprinkler heads and the boxing is secured simply by screw fixing to timber battens or aluminium angles, which also allows easy access for inspection and routine sprinkler maintenance.

A range of dedicated accessories is also available including internal and external corners, as well as stop ends. Running lengths are butted end to end to ensure the integrity of the boxing. Intumescent mastic joint sealant may also be required.

- Manufactured from FR Euroclass B standard compliant board

- Designed primarily for high level horizontal applications

- Suitable for use in flats, lift lobbies and communal areas

- FSC® Chain of Custody certified and compliant

- Consistent and uniform finish

- Painted white finish

- Easy to remove for access

- Range of dedicated accessories

- Column Casing

- Pipe Boxing & Fire Sprinkler Boxing

- Interior Wall Linings

- Boiler Pipe Work Casing

- Perimeter & HVAC Casings

- Supply & Installation

Our extensive pre-formed plywood pipe boxing and boiler pipe work casings ranges are widely used in countless public and private sector projects, from ‘Decent Homes Standard' social housing refurbishment programmes to new homes constructed by major house builders.

Online Shop

Whether you’re a builder, plumber or just doing a spot of DIY, then you should be able to find what you need from our wide product range, although, if you need some assistance, advice or can't see exactly the right solution, then please give us a call and we will be able to help.

Also, Next Working Day Delivery is available on all Encasement pipe boxing and boiler casings when you order before 1:30 pm excluding statutory holidays.

As our products are already used throughout the UK and Europe in a wide range of private and public sector projects, from social housing RMI programmes to meet Decent Homes standards, to new homes contracts with major house builders, you can be confident of our quality service and support. Also, all our pre-formed pipe boxing and boiler pipe casings now carry a two year guarantee as standard, for even greater peace of mind.

Our column casings range continues to go from strength to strength and is now the widest available in the UK, incorporating seven core ranges covering internal and external applications as well as a diversity of styles, finishes and shapes

Our Column Casings range includes:

- Circa – pre-formed circular plywood including FSC certified option

- Quadra – preformed square and rectangular casings including FSC certified option

- Forma – metal column casings including aluminium, stainless steel and steel

- Polyma – glass reinforced polymer

- Gypra – glass reinforced gypsum

- Metza – provides up to 1 hour fire protection specifically for mezzanine floor columns

Gallery

Videos

News

The versatility and choice available within our column casings range has been driven by the demands of architects and specifiers seeking to create a stylish finish to building interiors and exteriors.

A key element in the design freedom provided by our range is the choice of materials available to meet different specifications and applications. From Circa and Quadra pre-formed plywood casings, through to Polyma GRP and Gypra GRG, as well as our Forma metal range, each allows an array of specification options to be accommodated, including shapes, sizes and finishes.

Used extensively in a range of sectors including transport, health, education, retail, hotel and leisure, as well as commercial refurbishment and building re-purposing projects, our range also offers an exceptional choice of standard and bespoke manufactured options.

Projects such as Tetrosyl’s Rochdale offices; Cardiff Premier Inn, Porsche West London and Farnborough Sixth Form College, have all taken advantage of the design versatility, material options, choice of finishes and our bespoke manufacturing capabilities to meet specific requirements of each project.

In addition to these, our column casings have been installed on countless other projects throughout the UK to provide aesthetic and practical solutions for concealing structural columns and steelwork, while also helping create stylish decorative interiors and exteriors.

Alongside our wide range of products, we also offer a supply and install service, enabling us to maintain complete control over the project and provide expert installation solutions for any column casing project.

Whatever your casing requirements – We’ve got them covered.

A key element in the design freedom provided by our range is the choice of materials available to meet different specifications and applications. From Circa and Quadra pre-formed plywood casings, through to Polyma GRP and Gypra GRG, as well as our Forma metal range, each allows an array of specification options to be accommodated, including shapes, sizes and finishes.

Used extensively in a range of sectors including transport, health, education, retail, hotel and leisure, as well as commercial refurbishment and building re-purposing projects, our range also offers an exceptional choice of standard and bespoke manufactured options.

Projects such as Tetrosyl’s Rochdale offices; Cardiff Premier Inn, Porsche West London and Farnborough Sixth Form College, have all taken advantage of the design versatility, material options, choice of finishes and our bespoke manufacturing capabilities to meet specific requirements of each project.

In addition to these, our column casings have been installed on countless other projects throughout the UK to provide aesthetic and practical solutions for concealing structural columns and steelwork, while also helping create stylish decorative interiors and exteriors.

Alongside our wide range of products, we also offer a supply and install service, enabling us to maintain complete control over the project and provide expert installation solutions for any column casing project.

Whatever your casing requirements – We’ve got them covered.

Although health has been at the front of everyone’s minds over the past 18 months, the healthcare sector has been a key user of Encasement decorative casing solutions for many years, to help improve the interior design and add to the patient experience whilst also concealing structural elements.

As hospitals and health centres are designed around the high volumes of people in foyers, reception areas and corridors, this requires decorative casings to be highly durable to cope with staff, visitors and patients, while also being easy to clean to maintain hygiene.

To achieve the required combination of durability, aesthetics and low maintenance, several of our column casing ranges are regularly used. The pre-formed plywood ‘Circa’ and ‘Quadra’ column casings ranges, with a tough laminated finish, are used for high traffic interior applications while the metal ‘Forma’ range and ‘Polyma’ GRP casings can be used in both exterior and interior projects.

Circa and Quadra allow circular, square and rectangular profiles to be specified while also providing a wide range of finish options, with the most popular being decorative laminates which have very good resistance to damage, scuffs and scratches. They also offer specifiers a diverse palette of finishes.

Strength, durability and colour choice are also features of the Polyma GRP range. As they are produced from moulds, a high degree of design flexibility is possible with shape; size and colour options all open to specification to meet bespoke project requirements.

Projects in health centres, care homes and special care housing utilise this versatility well, as the casings are specified with elliptical profiles to minimise the casing’s footprint and allow easy access around the casing when used in corridors.

Polyma casings can also be manufactured in a range of colours to not only integrate with the interior design but also help improve safety for people with visual impairments, by adding colour and contrast, where required.

Forma aluminium or stainless-steel column casings are also extremely versatile and can be specified in circular, square, rectangular or hexagonal forms, as well as unique bespoke shapes. A wide choice of finishes is available including PPC coating in any RAL colour, as well as brushed, anodised, embossed, or textured finishes such as Rimex.

Projects at Birmingham Dental Hospital and Northwick Park Hospital in Harrow, perfectly illustrate the high degree of versatility within this range. In Birmingham, the decorative benefits of Forma are utilised in the building’s interior, with semi-elliptical casings concealing structural supports on the glazed façade, while at Northwick Park, Forma is used outside to provide weather-resistant square casings for the structural supports on the hospital’s new car park.

As hospitals and health centres are designed around the high volumes of people in foyers, reception areas and corridors, this requires decorative casings to be highly durable to cope with staff, visitors and patients, while also being easy to clean to maintain hygiene.

To achieve the required combination of durability, aesthetics and low maintenance, several of our column casing ranges are regularly used. The pre-formed plywood ‘Circa’ and ‘Quadra’ column casings ranges, with a tough laminated finish, are used for high traffic interior applications while the metal ‘Forma’ range and ‘Polyma’ GRP casings can be used in both exterior and interior projects.

Circa and Quadra allow circular, square and rectangular profiles to be specified while also providing a wide range of finish options, with the most popular being decorative laminates which have very good resistance to damage, scuffs and scratches. They also offer specifiers a diverse palette of finishes.

Strength, durability and colour choice are also features of the Polyma GRP range. As they are produced from moulds, a high degree of design flexibility is possible with shape; size and colour options all open to specification to meet bespoke project requirements.

Projects in health centres, care homes and special care housing utilise this versatility well, as the casings are specified with elliptical profiles to minimise the casing’s footprint and allow easy access around the casing when used in corridors.

Polyma casings can also be manufactured in a range of colours to not only integrate with the interior design but also help improve safety for people with visual impairments, by adding colour and contrast, where required.

Forma aluminium or stainless-steel column casings are also extremely versatile and can be specified in circular, square, rectangular or hexagonal forms, as well as unique bespoke shapes. A wide choice of finishes is available including PPC coating in any RAL colour, as well as brushed, anodised, embossed, or textured finishes such as Rimex.

Projects at Birmingham Dental Hospital and Northwick Park Hospital in Harrow, perfectly illustrate the high degree of versatility within this range. In Birmingham, the decorative benefits of Forma are utilised in the building’s interior, with semi-elliptical casings concealing structural supports on the glazed façade, while at Northwick Park, Forma is used outside to provide weather-resistant square casings for the structural supports on the hospital’s new car park.

As retailers re-open and shoppers return to the high street, malls and retail parks, the importance of combining practicality with decorative design is still important to ensure the shopping experience is enhanced.

Decorative casings, such as column casings and wall linings, are a fundamental part of retail design and in addition to providing a practical method of concealing interior and exterior structural steelwork, they also add to a building’s aesthetics.

For almost 15 years, Encasement has been manufacturing and supplying column casing and wall lining solutions to a diverse range of retailers covering the grocery sector, homeware, clothing, furniture stores, restaurants and automotive dealerships

Our range provides architects, specifiers and designers with a wide choice of materials and finishes, as well as bespoke shapes and dimensions, so it should be no surprise that our products are used by many well-known brands. These include, Halfords, Porsche, Tesco, ASDA, Oak Furnitureland, Kia Motors and Greggs, as well as major retail parks and shopping centres across the UK.

The ‘Circa’ and ‘Quadra’ column casings ranges are manufactured from pre-formed plywood, while ‘Forma’ casing are fabricated from metal and the ‘Polyma’ and ‘Gypra’ casings are produced from moulds in glass reinforced plastic (GRP) and glass reinforced gypsum (GRG) respectively.

‘Circa’ and ‘Quadra’ allow circular, square and rectangular profiles to be specified while also providing a wide range of finish options with the most popular being decorative laminates, which have very good resistance to damage, scuffs and scratches. They also offer specifiers a diverse palette of finishes including plain colours, wood grains and metallics, as well as textured and real wood veneers.

While all our casings ranges can be used for building interiors use, ‘Polyma’ and ‘Forma’ casings are also widely used for exterior retail projects, due to their inherent weather resistance and durability.

Available in aluminium or stainless steel, ‘Forma’ casings offer a diverse range of options and can be specified in circular, square, rectangular or hexagonal forms, as well as unique bespoke shapes. A wide choice of finishes is available including PPC coating in any RAL colour, as well as brushed, anodised, embossed or textured finishes such as Rimex.

Strength, durability and colour choice are also features of the ‘Polyma’ GRP range. As they are produced from moulds, a high degree of design flexibility is possible with shape; size and colour options all open to specification to meet bespoke project requirements.

Alongside our column casings, our ‘Vecta’ building linings system provides a high quality solution for interior wall linings, bulkheads and reveals and are regularly specified for supermarkets, automotive retail, restaurant and food brands including Tesco, Prêt a Manger, Mini and Greggs.

By offering six different column casing ranges and the ‘Vecta’ decorative wall linings system, specifiers can source a range of specialised interior finish products from a single company, supported by high levels of experience in this sector. We also offer a full supply and install service to support contractors.

Decorative casings, such as column casings and wall linings, are a fundamental part of retail design and in addition to providing a practical method of concealing interior and exterior structural steelwork, they also add to a building’s aesthetics.

For almost 15 years, Encasement has been manufacturing and supplying column casing and wall lining solutions to a diverse range of retailers covering the grocery sector, homeware, clothing, furniture stores, restaurants and automotive dealerships

Our range provides architects, specifiers and designers with a wide choice of materials and finishes, as well as bespoke shapes and dimensions, so it should be no surprise that our products are used by many well-known brands. These include, Halfords, Porsche, Tesco, ASDA, Oak Furnitureland, Kia Motors and Greggs, as well as major retail parks and shopping centres across the UK.

The ‘Circa’ and ‘Quadra’ column casings ranges are manufactured from pre-formed plywood, while ‘Forma’ casing are fabricated from metal and the ‘Polyma’ and ‘Gypra’ casings are produced from moulds in glass reinforced plastic (GRP) and glass reinforced gypsum (GRG) respectively.

‘Circa’ and ‘Quadra’ allow circular, square and rectangular profiles to be specified while also providing a wide range of finish options with the most popular being decorative laminates, which have very good resistance to damage, scuffs and scratches. They also offer specifiers a diverse palette of finishes including plain colours, wood grains and metallics, as well as textured and real wood veneers.

While all our casings ranges can be used for building interiors use, ‘Polyma’ and ‘Forma’ casings are also widely used for exterior retail projects, due to their inherent weather resistance and durability.

Available in aluminium or stainless steel, ‘Forma’ casings offer a diverse range of options and can be specified in circular, square, rectangular or hexagonal forms, as well as unique bespoke shapes. A wide choice of finishes is available including PPC coating in any RAL colour, as well as brushed, anodised, embossed or textured finishes such as Rimex.

Strength, durability and colour choice are also features of the ‘Polyma’ GRP range. As they are produced from moulds, a high degree of design flexibility is possible with shape; size and colour options all open to specification to meet bespoke project requirements.

Alongside our column casings, our ‘Vecta’ building linings system provides a high quality solution for interior wall linings, bulkheads and reveals and are regularly specified for supermarkets, automotive retail, restaurant and food brands including Tesco, Prêt a Manger, Mini and Greggs.

By offering six different column casing ranges and the ‘Vecta’ decorative wall linings system, specifiers can source a range of specialised interior finish products from a single company, supported by high levels of experience in this sector. We also offer a full supply and install service to support contractors.

Where external pipework needs to be concealed and protected against the risk of accidental damage, vandalism or theft, Arma metal pipe boxing provides a tough and versatile solution that also improves aesthetics and adds a uniform finish to the project.

Already widely used in a range of social housing refurbishment applications to conceal and protect simple vertical and horizontal pipe runs, as well as more complex district heating and central boiler installations, Arma can help improve security on projects at risk from damage.

All Arma metal boxing is bespoke manufactured from strong, lightweight and corrosion resistant aluminium, to meet the dimensions and requirement of individual projects, which eases installation and improves the fit and finish.

Arma’s ‘U’ shaped channel profiles are available with either a flange or angle fixing method, enabling them to be readily secured to the external walls with suitable fixings, while lockable hinged inspection doors can also be incorporated to simplify routing maintenance on pipework.

To contrast or blend in with wall colours and surroundings, Arma can be specified with a PPC finish in any RAL paint colour. Pre-formed internal and external corners, together with joint covers and end caps are also available as part of the range. We also offer a supply and install service on the Arma product range to help simplify installation process.

Key Features

Damage protection for external pipework and services

Strong & durable aluminium construction

Range of sizes and fitting options

PPC finishes in a wide range of RAL colours

Easy to install

Already widely used in a range of social housing refurbishment applications to conceal and protect simple vertical and horizontal pipe runs, as well as more complex district heating and central boiler installations, Arma can help improve security on projects at risk from damage.

All Arma metal boxing is bespoke manufactured from strong, lightweight and corrosion resistant aluminium, to meet the dimensions and requirement of individual projects, which eases installation and improves the fit and finish.

Arma’s ‘U’ shaped channel profiles are available with either a flange or angle fixing method, enabling them to be readily secured to the external walls with suitable fixings, while lockable hinged inspection doors can also be incorporated to simplify routing maintenance on pipework.

To contrast or blend in with wall colours and surroundings, Arma can be specified with a PPC finish in any RAL paint colour. Pre-formed internal and external corners, together with joint covers and end caps are also available as part of the range. We also offer a supply and install service on the Arma product range to help simplify installation process.

Key Features

Damage protection for external pipework and services

Strong & durable aluminium construction

Range of sizes and fitting options

PPC finishes in a wide range of RAL colours

Easy to install

When it comes to durable and decorative casings for transport projects, the extensive Encasement range has them covered.

The constant footfall and traffic created by passengers, places specific demands on column casings and wall linings, as they need to be durable enough to resist scuffs and scrapes, whilst also integrating with a building’s design, whether it’s an airport, train station or bus terminus.

Our column casings and building linings have been developed to meet most transport sector projects requirements by providing a choice of materials and finishes that allow a wide range of specification options.

For interior use only, our Circa and Quadra column casings give increased versatility, as they are available in a range of standard dimensions or can be specified with bespoke sizes and shapes. Manufactured from pre-formed ply and usually specified with a tough high-pressure laminate (HPL) finish, these are regularly specified for transport hubs and related applications.

In addition, our Forma metal and Polyma GRP column casings can be specified for both interior or exterior use, as their inherent weather resistance, durable materials and an exceptionally wide choice of finishes enable even greater design freedom.

Standard sizes are available in both ranges, although they are also ideally suited for bespoke shapes and dimensions, as Forma is manufactured from aluminium or stainless steel and the Polyma range is produced from moulds, which can be specified to suit individual project requirements.

For many transport hubs, the interior walls also require a combination of protection and aesthetics to resist accidental damage, provide long life and minimise maintenance whilst also providing a decorative finish in areas, such as waiting rooms, foyers, and check-in areas.

Our Vecta building linings are manufactured to meet individual project specifications and can be specified in a range of materials, including natural, brushed, anodised or PPC coated metal, as well as compact laminate wall linings, which are available in a wide palette of colours.

These can also incorporate custom images or graphics for unique interior design or branding solutions. We also have our own contracting arm, which enables us to offer a full supply and install service to support contractors.

The constant footfall and traffic created by passengers, places specific demands on column casings and wall linings, as they need to be durable enough to resist scuffs and scrapes, whilst also integrating with a building’s design, whether it’s an airport, train station or bus terminus.

Our column casings and building linings have been developed to meet most transport sector projects requirements by providing a choice of materials and finishes that allow a wide range of specification options.

For interior use only, our Circa and Quadra column casings give increased versatility, as they are available in a range of standard dimensions or can be specified with bespoke sizes and shapes. Manufactured from pre-formed ply and usually specified with a tough high-pressure laminate (HPL) finish, these are regularly specified for transport hubs and related applications.

In addition, our Forma metal and Polyma GRP column casings can be specified for both interior or exterior use, as their inherent weather resistance, durable materials and an exceptionally wide choice of finishes enable even greater design freedom.

Standard sizes are available in both ranges, although they are also ideally suited for bespoke shapes and dimensions, as Forma is manufactured from aluminium or stainless steel and the Polyma range is produced from moulds, which can be specified to suit individual project requirements.

For many transport hubs, the interior walls also require a combination of protection and aesthetics to resist accidental damage, provide long life and minimise maintenance whilst also providing a decorative finish in areas, such as waiting rooms, foyers, and check-in areas.

Our Vecta building linings are manufactured to meet individual project specifications and can be specified in a range of materials, including natural, brushed, anodised or PPC coated metal, as well as compact laminate wall linings, which are available in a wide palette of colours.

These can also incorporate custom images or graphics for unique interior design or branding solutions. We also have our own contracting arm, which enables us to offer a full supply and install service to support contractors.

One of the latest hotels from the Premier Inn chain in Cardiff Bay is using bespoke ’Polyma’ GRP column casings from Encasement to conceal diagonal structural steelwork that runs along the full length of the building while adding a distinctive and colourful feature due to their bright yellow finish.

Although the successful regeneration and development of Cardiff Bay has attracted a wide range of businesses and stimulated tourism, it has also exposed a shortfall in quality hotel accommodation in the area, which the new Premier Inn is helping to address.

Designed by Holder Mathias Architects as part of the £40 million Cardiff Waterside development that also includes two office buildings, the eight-storey hotel has 210 double, twin and family rooms, together with a restaurant, bar and meeting facilities.

As Cardiff Bay includes an eclectic mix of building types and styles, ranging from ultra-modern angular office buildings to mid-nineteenth century structures, the Premier Inn’s unique exterior design reflects the area’s characteristics with the use of ’punched hole’ widows, brick style facade and Encasement’s bright yellow casings.

An integral aspect of the building’s steel frame construction is the use of diagonal square section supports below a sharp cantilevered edge on the front elevation, which is joined at the top and base to create a continuous angular design.

To conceal the structural steelwork and enhance the building’s aesthetics, Encasement’s Polyma GRP range was used, as it is weatherproof and resistant to damage, which makes it ideal for exterior use.

Encasement manufactured and installed 40 column casing sections, each measuring 400mm in diameter and 3860mm in length, together with 40 bespoke ’V’ shaped casing sections and two single casings to conceal the fixing brackets at each end.

Due to the unique casing design, all the casings were manufactured from 10mm thick GRP, which was hand-laid in moulds to give a precise form, while ensuring the casings incorporated the specified high-quality yellow RAL 1018 Gel-coat finish.

Each casing was designed to work as a two-part design, which enables the casing to be placed around the structural steelwork before being secured and the joint lines concealed using colour-matched polymer filler.

To ensure the system fitted perfectly over the steelwork, Encasement constructed a framework within the column casing, which is fixed to the steelwork and provides continuous support to each component. This also allows each casing to be secured to the frame and hold each element securely in place to provide a strong and rigid solution.

Encasement’s Managing Director, Martin Taylor, explained: “We have been involved in a wide range of projects requiring casing solutions of all shapes, sizes and materials. Some are purely for aesthetic reasons; while others take advantage of a particular material’s characteristics that overcome a specific technical challenge or meet a unique specification requirement.

“However, with this project, the casings were not only genuinely unique, to accommodate the layout of the building’s steel support structure, but also had to have good damage resistance, excellent weather-proof performance and make a bold aesthetic statement for one of the UK’s best-known hotel brands.”

He added: “The end result speaks for itself, as the finished project not only looks dramatic but also meets all the client’s technical and performance specifications. We’re delighted to have played a part in this excellent project.”

Although the successful regeneration and development of Cardiff Bay has attracted a wide range of businesses and stimulated tourism, it has also exposed a shortfall in quality hotel accommodation in the area, which the new Premier Inn is helping to address.

Designed by Holder Mathias Architects as part of the £40 million Cardiff Waterside development that also includes two office buildings, the eight-storey hotel has 210 double, twin and family rooms, together with a restaurant, bar and meeting facilities.

As Cardiff Bay includes an eclectic mix of building types and styles, ranging from ultra-modern angular office buildings to mid-nineteenth century structures, the Premier Inn’s unique exterior design reflects the area’s characteristics with the use of ’punched hole’ widows, brick style facade and Encasement’s bright yellow casings.

An integral aspect of the building’s steel frame construction is the use of diagonal square section supports below a sharp cantilevered edge on the front elevation, which is joined at the top and base to create a continuous angular design.

To conceal the structural steelwork and enhance the building’s aesthetics, Encasement’s Polyma GRP range was used, as it is weatherproof and resistant to damage, which makes it ideal for exterior use.

Encasement manufactured and installed 40 column casing sections, each measuring 400mm in diameter and 3860mm in length, together with 40 bespoke ’V’ shaped casing sections and two single casings to conceal the fixing brackets at each end.

Due to the unique casing design, all the casings were manufactured from 10mm thick GRP, which was hand-laid in moulds to give a precise form, while ensuring the casings incorporated the specified high-quality yellow RAL 1018 Gel-coat finish.

Each casing was designed to work as a two-part design, which enables the casing to be placed around the structural steelwork before being secured and the joint lines concealed using colour-matched polymer filler.

To ensure the system fitted perfectly over the steelwork, Encasement constructed a framework within the column casing, which is fixed to the steelwork and provides continuous support to each component. This also allows each casing to be secured to the frame and hold each element securely in place to provide a strong and rigid solution.

Encasement’s Managing Director, Martin Taylor, explained: “We have been involved in a wide range of projects requiring casing solutions of all shapes, sizes and materials. Some are purely for aesthetic reasons; while others take advantage of a particular material’s characteristics that overcome a specific technical challenge or meet a unique specification requirement.

“However, with this project, the casings were not only genuinely unique, to accommodate the layout of the building’s steel support structure, but also had to have good damage resistance, excellent weather-proof performance and make a bold aesthetic statement for one of the UK’s best-known hotel brands.”

He added: “The end result speaks for itself, as the finished project not only looks dramatic but also meets all the client’s technical and performance specifications. We’re delighted to have played a part in this excellent project.”

Without column casings and interior wall lining solutions, many schools, colleges and universities would be considerably less attractive and engaging learning environments, but as they are usually required to integrate with a building’s interior or exterior design, they can’t be overlooked.

Column casings and wall linings are primarily installed to conceal structural steelwork and building services while also providing a decorative and more aesthetic finish that can blend in or contrast with the decor.

However, the presence of large numbers of students and the use of decorative casings in high traffic areas, such as main entrances, common rooms, foyers, sports halls and other public spaces, has an important influence on their specification, as durability is an essential requirement for most projects.

The ability to understand and meet these demands from architects, educational design teams and specifiers have been key factors that have influenced the wide range of products manufactured and supplied by Peterborough based specialist, Encasement Ltd.

Encasement is probably best known for its extensive column casings range, which includes pre-formed plywood and glass reinforced gypsum (GRG), exclusively for interior applications, as well as aluminium, stainless steel and glass reinforced polymer (GRP) casings, which are suitable for interior and exterior for use due to their durability and inherent weather resistance.

Perhaps unsurprisingly, it is the company’s ’Forma’ metal casings and ’Polyma’ GRP range that are widely used in educational buildings, where their toughness and choice of finishes make them an ideal solution. Forma, particularly, provides specifiers with an exceptional scope of options and can be specified in a range of shapes including circular, up to 1000mm diameter, or as square, rectangular, hexagonal or bespoke forms.

In addition to recent installations at Bishop Vesey’s Grammar School and St. Richard Reynolds College, which used Rimex textured aluminium, further projects at Winchester College, Birmingham University Dental School and Liverpool University’s Donnan Laboratories, have all exploited the practical and diverse decorative properties of Encasement’s ’Forma’ range.

Together with Forma, Encasement’s ’Circa’ and ’Quadra’ ranges are also used in educational building interiors. While both ranges are manufactured from FSC® certified plywood to comply with sustainability codes and environmental procurement policies, the main difference between the two types is their shape. Circa covers applications where round and extended circular forms are specified, while Quadra provides designers with the option to use square and rectangular profiles.

Their unrivalled palette of finishes, includes plain, textured and patterned laminates, from specialists such as Formica and Polyrey, together with real wood veneers. They can also be left plain for painting on site in any colour. However, a combination of diverse colour options and resistance to scuffs and scratches has made decorative laminates the most popular for education projects.

The Dame Kelly Holmes Sports Centre and Farnborough Sixth Form College are typical examples of how Quadra casings effectively conceal structural steelwork while their colourful and durable finishes enhance the interior design.

Alongside the company’s six individual ranges of column casings, its ’Vecta’ system provides a high quality solution for interior wall linings, bulkheads and reveals. Vecta has been used in a range of interior education projects, including extensive remodelling of London’s South Bank University, as well as exterior applications, such as the overhead walkway casings at St. Richard Reynolds College in Twickenham.

Encasement’s Managing Director, Martin Taylor, commented: “Column casings provide a perfect mix of practicality and aesthetics, which are essential considerations for all educational buildings.

In addition, our Vecta system allows specifiers to source a range of specialised interior finish products from a single company with high levels of expertise and experience in this sector. We also have our own contracting arm, which enables us to offer a full supply and install service to support contractors.”

Column casings and wall linings are primarily installed to conceal structural steelwork and building services while also providing a decorative and more aesthetic finish that can blend in or contrast with the decor.

However, the presence of large numbers of students and the use of decorative casings in high traffic areas, such as main entrances, common rooms, foyers, sports halls and other public spaces, has an important influence on their specification, as durability is an essential requirement for most projects.

The ability to understand and meet these demands from architects, educational design teams and specifiers have been key factors that have influenced the wide range of products manufactured and supplied by Peterborough based specialist, Encasement Ltd.

Encasement is probably best known for its extensive column casings range, which includes pre-formed plywood and glass reinforced gypsum (GRG), exclusively for interior applications, as well as aluminium, stainless steel and glass reinforced polymer (GRP) casings, which are suitable for interior and exterior for use due to their durability and inherent weather resistance.

Perhaps unsurprisingly, it is the company’s ’Forma’ metal casings and ’Polyma’ GRP range that are widely used in educational buildings, where their toughness and choice of finishes make them an ideal solution. Forma, particularly, provides specifiers with an exceptional scope of options and can be specified in a range of shapes including circular, up to 1000mm diameter, or as square, rectangular, hexagonal or bespoke forms.

In addition to recent installations at Bishop Vesey’s Grammar School and St. Richard Reynolds College, which used Rimex textured aluminium, further projects at Winchester College, Birmingham University Dental School and Liverpool University’s Donnan Laboratories, have all exploited the practical and diverse decorative properties of Encasement’s ’Forma’ range.

Together with Forma, Encasement’s ’Circa’ and ’Quadra’ ranges are also used in educational building interiors. While both ranges are manufactured from FSC® certified plywood to comply with sustainability codes and environmental procurement policies, the main difference between the two types is their shape. Circa covers applications where round and extended circular forms are specified, while Quadra provides designers with the option to use square and rectangular profiles.

Their unrivalled palette of finishes, includes plain, textured and patterned laminates, from specialists such as Formica and Polyrey, together with real wood veneers. They can also be left plain for painting on site in any colour. However, a combination of diverse colour options and resistance to scuffs and scratches has made decorative laminates the most popular for education projects.

The Dame Kelly Holmes Sports Centre and Farnborough Sixth Form College are typical examples of how Quadra casings effectively conceal structural steelwork while their colourful and durable finishes enhance the interior design.

Alongside the company’s six individual ranges of column casings, its ’Vecta’ system provides a high quality solution for interior wall linings, bulkheads and reveals. Vecta has been used in a range of interior education projects, including extensive remodelling of London’s South Bank University, as well as exterior applications, such as the overhead walkway casings at St. Richard Reynolds College in Twickenham.

Encasement’s Managing Director, Martin Taylor, commented: “Column casings provide a perfect mix of practicality and aesthetics, which are essential considerations for all educational buildings.

In addition, our Vecta system allows specifiers to source a range of specialised interior finish products from a single company with high levels of expertise and experience in this sector. We also have our own contracting arm, which enables us to offer a full supply and install service to support contractors.”

An £8.1 million events building at the National Memorial Arboretum in Staffordshire, is using external decorative column casings, bulkheads and parapet capping from Encasement to conceal structural steelwork and enhance the building’s exterior for the thousands of visitors it receives each year.

Designed by Glenn Howells Architects (GHA), the ’Aspects’ events building provides a permanent facility with flexible spaces at the Arboretum enabling a wide range of events to be held in the 2,500 sq.m building, which incorporates a banqueting kitchen, lounge area and configurations to host up to 500 people.

Both the main entrance canopy and the covered terrace area at the rear of the building are supported by 12 structural columns, each of which are concealed by 200mm square decorative casings from Encasement’s Forma range of metal casings.

Standing 4,500mm high, the column casings are manufactured from Alucobond®, an architectural composite that bonds an aluminium skin to a flame retardant or non-combustible core material to give a strong, lightweight and safe decorative solution.

As the building makes extensive use of glazing to provide panoramic views of the Arboretum site, Encasement also supplied a further eight Forma Alucobond ’half-column’ casings to conceal the glazing system’s external vertical supports to integrate with the building’s exterior design.

To maintain a consistent exterior finish, 20 Alucobond exterior bulkheads from Encasement’s ’Vecta’ range were supplied by the company in sections along with a series of PPC coated aluminium parapet cappings.

Martin Taylor, Encasement’s Managing Director, commented, ’’This new building is an excellent addition to the high quality visitor facilities already available at the Arboretum. The quality of the design, construction and the attention to detail is typified by the architect’s specification for the use of Alucobond for the casings solutions, which gives a perfect finish to the building.’’

Further information on the company’s range of column casings and other architectural casing products for can be obtained by visiting www.encasement.co.uk; e-mailing sales@encasement.co.uk or by calling 01733 266889.

Designed by Glenn Howells Architects (GHA), the ’Aspects’ events building provides a permanent facility with flexible spaces at the Arboretum enabling a wide range of events to be held in the 2,500 sq.m building, which incorporates a banqueting kitchen, lounge area and configurations to host up to 500 people.

Both the main entrance canopy and the covered terrace area at the rear of the building are supported by 12 structural columns, each of which are concealed by 200mm square decorative casings from Encasement’s Forma range of metal casings.

Standing 4,500mm high, the column casings are manufactured from Alucobond®, an architectural composite that bonds an aluminium skin to a flame retardant or non-combustible core material to give a strong, lightweight and safe decorative solution.

As the building makes extensive use of glazing to provide panoramic views of the Arboretum site, Encasement also supplied a further eight Forma Alucobond ’half-column’ casings to conceal the glazing system’s external vertical supports to integrate with the building’s exterior design.

To maintain a consistent exterior finish, 20 Alucobond exterior bulkheads from Encasement’s ’Vecta’ range were supplied by the company in sections along with a series of PPC coated aluminium parapet cappings.

Martin Taylor, Encasement’s Managing Director, commented, ’’This new building is an excellent addition to the high quality visitor facilities already available at the Arboretum. The quality of the design, construction and the attention to detail is typified by the architect’s specification for the use of Alucobond for the casings solutions, which gives a perfect finish to the building.’’

Further information on the company’s range of column casings and other architectural casing products for can be obtained by visiting www.encasement.co.uk; e-mailing sales@encasement.co.uk or by calling 01733 266889.

The range of pipe boxing and casing solutions for social housing from Encasement Ltd continues to be in high demand with the growth in fire sprinkler installation; central heating upgrades and distributed heating system refurbishment projects all using the company’s specialised products.

Pre-formed plywood casings have been the preferred solution for social housing RMI for decades and with over 30 years manufacturing experience in the sector, Encasement estimates that more than 100,000 kilometres of its pipe-boxing have already been installed in social housing sites throughout the UK.

The company’s pipe boxing, boiler casings and fire sprinkler boxing are continually specified by HAs, LAs and their contractors for concealing interior pipework, while its ’Arma’ range of tough, lightweight aluminium casings are increasingly specified to conceal and protect exterior services, such as gas supply pipes, electrical cabling and distributed heating pipework.

Encasement was one of the first manufacturers and suppliers of decorative casings to achieve the FSC® Chain of Custody Certification from the Forestry Stewardship Council in 2010 and since then, the company has offered an FSC® certified option on its full range of pre-formed plywood casings to comply with customers’ sustainable procurement policies.

The company’s Riva; Versa 5 and Versa 8 ranges of pipe and fire sprinkler boxing products, together with its boiler pipe casing range, are pre-finished in white melamine so that they can be fitted quickly and easily, which removes the need for on site painting and helps save time and money on site.

Martin Taylor, Encasement’s Managing Director, explained: ’’From our experience of working with contractors on countless social housing projects where pipework needs to be concealed, we know that pipe and fire sprinkler boxing can be fitted in less than half the time of site made alternatives.”

For housing associations, local authorities and their contractors, this time saving provides a number of benefits. It helps ensure that heating systems, boilers and fire safety upgrades can be completed within shorter timescales. This minimises disruption for tenants and can also have a positive impact on improving maintenance and tenant satisfaction KPI’s.

Potentially the most important advantage is that the time taken to complete the projects can be reduced without compromising the quality or integrity of the installation, which can also help reduce costs.

’’From day one, we set out to manufacture and supply the most comprehensive range of pipe boxing and casing products for the social housing sector and we now offer more than 200 different products, profiles and sizes within our standard range, continued Martin Taylor.”

He added: ’’Our Versa range of pre-formed pipe boxing has rapidly become a key solution for concealing retro-fitted fire sprinkler pipework in flats and communal areas, whilst the launch of our flame retardant Versa ’FR’ boxing was a first for the market. Versa FR is also pre-finished in white, while our Arma aluminium casings can be specified and manufactured in any RAL colour.”

Pre-formed plywood casings have been the preferred solution for social housing RMI for decades and with over 30 years manufacturing experience in the sector, Encasement estimates that more than 100,000 kilometres of its pipe-boxing have already been installed in social housing sites throughout the UK.

The company’s pipe boxing, boiler casings and fire sprinkler boxing are continually specified by HAs, LAs and their contractors for concealing interior pipework, while its ’Arma’ range of tough, lightweight aluminium casings are increasingly specified to conceal and protect exterior services, such as gas supply pipes, electrical cabling and distributed heating pipework.

Encasement was one of the first manufacturers and suppliers of decorative casings to achieve the FSC® Chain of Custody Certification from the Forestry Stewardship Council in 2010 and since then, the company has offered an FSC® certified option on its full range of pre-formed plywood casings to comply with customers’ sustainable procurement policies.

The company’s Riva; Versa 5 and Versa 8 ranges of pipe and fire sprinkler boxing products, together with its boiler pipe casing range, are pre-finished in white melamine so that they can be fitted quickly and easily, which removes the need for on site painting and helps save time and money on site.

Martin Taylor, Encasement’s Managing Director, explained: ’’From our experience of working with contractors on countless social housing projects where pipework needs to be concealed, we know that pipe and fire sprinkler boxing can be fitted in less than half the time of site made alternatives.”

For housing associations, local authorities and their contractors, this time saving provides a number of benefits. It helps ensure that heating systems, boilers and fire safety upgrades can be completed within shorter timescales. This minimises disruption for tenants and can also have a positive impact on improving maintenance and tenant satisfaction KPI’s.

Potentially the most important advantage is that the time taken to complete the projects can be reduced without compromising the quality or integrity of the installation, which can also help reduce costs.

’’From day one, we set out to manufacture and supply the most comprehensive range of pipe boxing and casing products for the social housing sector and we now offer more than 200 different products, profiles and sizes within our standard range, continued Martin Taylor.”

He added: ’’Our Versa range of pre-formed pipe boxing has rapidly become a key solution for concealing retro-fitted fire sprinkler pipework in flats and communal areas, whilst the launch of our flame retardant Versa ’FR’ boxing was a first for the market. Versa FR is also pre-finished in white, while our Arma aluminium casings can be specified and manufactured in any RAL colour.”

The publication of the Phase 1 report from the Grenfell Tower Inquiry in late October 2019 was yet another stark reminder, if one was needed, of the essential role that fire safety plays in all residential buildings, but particularly in high-rise blocks.

Even though the Inquiry’s Chairman has said that fire sprinkler systems will form an important part of the Phase 2 investigation this year, many pro-active HA and local authority landlords have begun implementing a major programme of fire protection upgrades, which includes the retro-fitting of fire sprinkler systems.

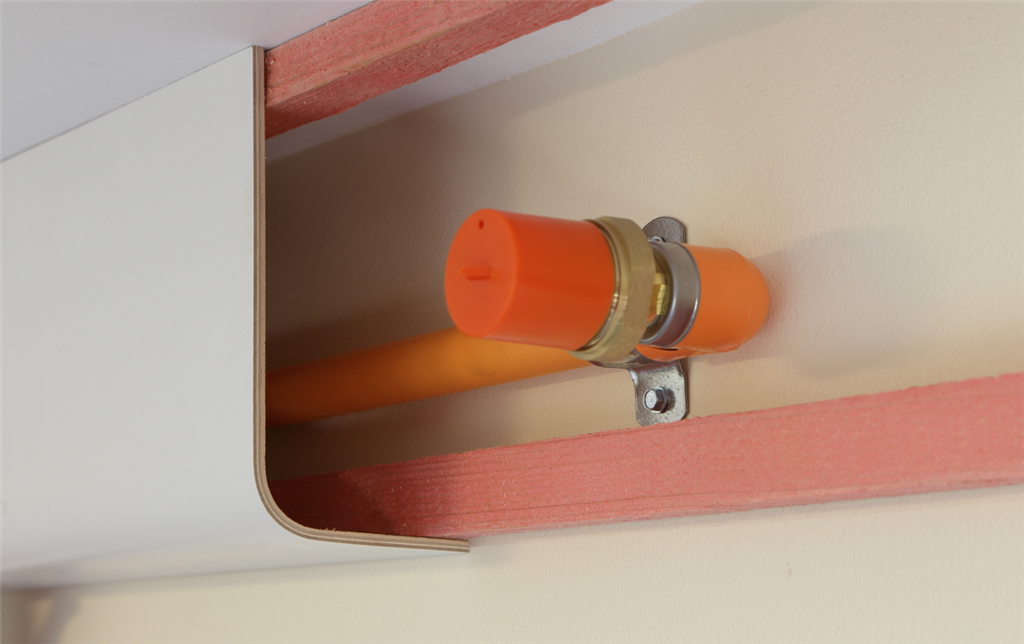

As sprinklers need to be located within individual flats and communal areas to suppress fires and aid escape, incorporating them in new builds is comparatively simple, as they can be integrated at the building design stage and pipework can be hidden within wall cavities and ceiling voids. For retro-fitted solutions, however, it’s not that straightforward, as in most cases the pipework will need to be surface mounted.

Once the sprinkler system pipework is installed, it needs to be concealed, as it provides a more aesthetic finish to each project and helps avoid potential complaints from tenants about unsightly orange pipes. It also serves a practical purpose of containing the components and acting as a visible barrier to potential tampering or accidental damage.

One of the main advantages of surface mounted pipework, is the simplicity and speed with which it can be installed by skilled contractors, so it’s important that the chosen method of pipe boxing is also quick and easy, as installation time and the associated costs are essential considerations on any sprinkler project. Consequently, these are key reasons why pre-formed and pre-finished solutions, such as Encasement’s Versa fire sprinkler pipe boxing, have become the preferred solution for many sprinkler contractors.

Versa ‘L’ shaped pipe boxing is manufactured from 5mm or 8mm thick plywood in a range of sizes and profiles and the system also includes dedicated accessories, such as internal and external corners, which help create an integrated finish and speeds the sprinkler installation. All that’s needed to install the sprinkler pipe boxing on site is to drill the holes for sprinkler heads, cut to length and secure to the wall or ceiling with wood battens, screws and caps.

From our experience of working with contractors on countless social housing projects where pipework needs to be concealed, Versa pipe and fire sprinkler boxing can be fitted in less than half the time of site made alternatives. Also, as it is pre-finished with durable white melamine, there’s no painting required on site, which saves further time and cost.

For housing associations, local authorities and their contractors, this time saving provides a number of benefits. It helps ensure that fire safety upgrades can be completed within shorter timescales and simultaneously minimises the disruption for tenants while the work is being carried out. Potentially the most important advantage is that the time taken to complete the projects can be reduced without compromising the quality or integrity of the installation, which can also reduce costs.

The over-riding aims must be to focus on helping save lives and enhance fire safety in high-rise residential buildings to avoid a repeat of the Grenfell tragedy. Fire sprinkler systems have an important role to play and Versa boxing solutions can make a contribution to that process in terms of effectiveness, ease of installation and economics.

Even though the Inquiry’s Chairman has said that fire sprinkler systems will form an important part of the Phase 2 investigation this year, many pro-active HA and local authority landlords have begun implementing a major programme of fire protection upgrades, which includes the retro-fitting of fire sprinkler systems.

As sprinklers need to be located within individual flats and communal areas to suppress fires and aid escape, incorporating them in new builds is comparatively simple, as they can be integrated at the building design stage and pipework can be hidden within wall cavities and ceiling voids. For retro-fitted solutions, however, it’s not that straightforward, as in most cases the pipework will need to be surface mounted.

Once the sprinkler system pipework is installed, it needs to be concealed, as it provides a more aesthetic finish to each project and helps avoid potential complaints from tenants about unsightly orange pipes. It also serves a practical purpose of containing the components and acting as a visible barrier to potential tampering or accidental damage.

One of the main advantages of surface mounted pipework, is the simplicity and speed with which it can be installed by skilled contractors, so it’s important that the chosen method of pipe boxing is also quick and easy, as installation time and the associated costs are essential considerations on any sprinkler project. Consequently, these are key reasons why pre-formed and pre-finished solutions, such as Encasement’s Versa fire sprinkler pipe boxing, have become the preferred solution for many sprinkler contractors.

Versa ‘L’ shaped pipe boxing is manufactured from 5mm or 8mm thick plywood in a range of sizes and profiles and the system also includes dedicated accessories, such as internal and external corners, which help create an integrated finish and speeds the sprinkler installation. All that’s needed to install the sprinkler pipe boxing on site is to drill the holes for sprinkler heads, cut to length and secure to the wall or ceiling with wood battens, screws and caps.

From our experience of working with contractors on countless social housing projects where pipework needs to be concealed, Versa pipe and fire sprinkler boxing can be fitted in less than half the time of site made alternatives. Also, as it is pre-finished with durable white melamine, there’s no painting required on site, which saves further time and cost.

For housing associations, local authorities and their contractors, this time saving provides a number of benefits. It helps ensure that fire safety upgrades can be completed within shorter timescales and simultaneously minimises the disruption for tenants while the work is being carried out. Potentially the most important advantage is that the time taken to complete the projects can be reduced without compromising the quality or integrity of the installation, which can also reduce costs.

The over-riding aims must be to focus on helping save lives and enhance fire safety in high-rise residential buildings to avoid a repeat of the Grenfell tragedy. Fire sprinkler systems have an important role to play and Versa boxing solutions can make a contribution to that process in terms of effectiveness, ease of installation and economics.

One of the latest hotels from the Premier Inn chain in Cardiff Bay is using bespoke ’Polyma’ GRP column casings from Encasement to conceal diagonal structural steelwork that runs along the full length of the building, while adding a distinctive and colourful feature due to their bright yellow finish.

Although the successful regeneration and development of Cardiff Bay has attracted a wide range of businesses and stimulated tourism, it has also exposed a shortfall in quality hotel accommodation in the area, which the new Premier Inn is helping to address.

Designed by Holder Mathias Architects as part of the £40 million Cardiff Waterside development that also includes two office buildings, the eight-storey hotel has 210 double, twin and family rooms, together with a restaurant, bar and meeting facilities.

As Cardiff Bay includes an eclectic mix of building types and styles, ranging from ultra modern angular office buildings to mid-nineteenth century structures, the Premier Inn’s unique exterior design reflect the area’s characteristics with the use of ’punched hole’ widows, brick style facade and Encasement’s bright yellow casings.

An integral aspect of the building’s steel frame construction is the use of diagonal square section supports below a sharp cantilevered edge on the front elevation, which are joined at the top and base to create a continuous angular design.

To conceal the structural steelwork and enhance the building’s aesthetics, Encasement’s Polyma GRP range was used, as it is weather proof and resistant to damage, which makes it ideal for exterior use.

Encasement manufactured and installed 40 column casing sections, each measuring 400mm in diameter and 3860mm in length, together with 40 bespoke ’V’ shaped casing sections and two single casings to conceal the fixing brackets at each end.

Due to the unique casing design, all the casings were manufactured from 10mm thick GRP, which was hand-laid in moulds to give a precise form, while ensuring the casings incorporated the specified high quality yellow RAL 1018 Gel-coat finish.

Each casing was designed to work as a two-part design, which enables the casing to be placed around the structural steelwork before being secured and the joint lines concealed using colour-matched polymer filler.

To ensure the system fitted perfectly over the steelwork, Encasement constructed a framework within the column casing, which is fixed to the steelwork and provides a continuous support to each component. This also allows each casing to be secured to the frame and hold each element securely in place to provide a strong and rigid solution.

Encasement’s Managing Director, Martin Taylor, explained: “We have been involved in a wide range of projects requiring casing solutions of all shapes, sizes and materials. Some are purely for aesthetic reasons; while others take advantage of a particular material’s characteristics that overcomes a specific technical challenge or meets a unique specification requirement.

“However, with this project, the casings were not only genuinely unique, to accommodate the layout of the building’s steel support structure, but also had to have good damage resistance, excellent weather-proof performance and make a bold aesthetic statement for one of the UK’s best known hotel brands.”

He added: “The end result speaks for itself, as the finished project not only looks dramatic, but also meets all the client’s technical and performance specifications. We’re delighted to have played a part in this excellent project.”

Although the successful regeneration and development of Cardiff Bay has attracted a wide range of businesses and stimulated tourism, it has also exposed a shortfall in quality hotel accommodation in the area, which the new Premier Inn is helping to address.

Designed by Holder Mathias Architects as part of the £40 million Cardiff Waterside development that also includes two office buildings, the eight-storey hotel has 210 double, twin and family rooms, together with a restaurant, bar and meeting facilities.

As Cardiff Bay includes an eclectic mix of building types and styles, ranging from ultra modern angular office buildings to mid-nineteenth century structures, the Premier Inn’s unique exterior design reflect the area’s characteristics with the use of ’punched hole’ widows, brick style facade and Encasement’s bright yellow casings.

An integral aspect of the building’s steel frame construction is the use of diagonal square section supports below a sharp cantilevered edge on the front elevation, which are joined at the top and base to create a continuous angular design.

To conceal the structural steelwork and enhance the building’s aesthetics, Encasement’s Polyma GRP range was used, as it is weather proof and resistant to damage, which makes it ideal for exterior use.

Encasement manufactured and installed 40 column casing sections, each measuring 400mm in diameter and 3860mm in length, together with 40 bespoke ’V’ shaped casing sections and two single casings to conceal the fixing brackets at each end.

Due to the unique casing design, all the casings were manufactured from 10mm thick GRP, which was hand-laid in moulds to give a precise form, while ensuring the casings incorporated the specified high quality yellow RAL 1018 Gel-coat finish.

Each casing was designed to work as a two-part design, which enables the casing to be placed around the structural steelwork before being secured and the joint lines concealed using colour-matched polymer filler.

To ensure the system fitted perfectly over the steelwork, Encasement constructed a framework within the column casing, which is fixed to the steelwork and provides a continuous support to each component. This also allows each casing to be secured to the frame and hold each element securely in place to provide a strong and rigid solution.

Encasement’s Managing Director, Martin Taylor, explained: “We have been involved in a wide range of projects requiring casing solutions of all shapes, sizes and materials. Some are purely for aesthetic reasons; while others take advantage of a particular material’s characteristics that overcomes a specific technical challenge or meets a unique specification requirement.

“However, with this project, the casings were not only genuinely unique, to accommodate the layout of the building’s steel support structure, but also had to have good damage resistance, excellent weather-proof performance and make a bold aesthetic statement for one of the UK’s best known hotel brands.”

He added: “The end result speaks for itself, as the finished project not only looks dramatic, but also meets all the client’s technical and performance specifications. We’re delighted to have played a part in this excellent project.”

Decorative casings solutions, such as column casings and wall linings, are a fundamental part of contemporary retail design. In addition to providing a practical method of concealing interior and exterior structural steelwork they also add to a building’s aesthetics, style and shopping experience.

This combination of practicality, versatility and decorative design has been at the centre of the wide range of retail projects that have been undertaken by Peterborough based casing solutions specialist, Encasement Ltd.

For almost 15 years, the company has been manufacturing and supplying column casing and wall lining solutions to a diverse range of retailers covering the grocery sector, home-wares, clothing, furniture stores, restaurants and automotive dealerships

As Encasement’s range provides architects, specifiers and designers with a wide choice of materials and finishes to choose from, as well as bespoke shapes and dimensions, it’s unsurprising that its products are used by many well known brands, including Debenhams, Porsche, Kia Motors, Tesco, ASDA, Oak Furnitureland and Greggs, as well as major retail parks and shopping centres across the UK.

Encasement’s column casings range includes ’Circa’ and ’Quadra’, which are manufactured from pre-formed plywood, together with the metal ’Forma’ range, ’Polyma’ and ’Gypra’ casings, which are moulded respectively from glass reinforced plastic (GRP) and glass reinforced gypsum (GRG).

In addition, the ’Metza’ range is a specialised solution that provides up to 2 hours fire protection. Originally designed for mezzanine support columns, Metza is also used in food retail fitted with corner protectors to resist scuffing and damage caused by shopping trolleys.

While every Encasement column casings is suitable for interior use, its ’Polyma’ and ’Forma’ ranges are also widely used for exterior retail projects, due to their inherent weather resistance and durability.

Available in aluminium or stainless steel, ’Forma’ casings offer a diverse range of options and can be specified as circles with diameters from 250mm up to 1000mm and in square, rectangular or hexagonal forms, as well as unique custom profiles. The choice of finishes is also very wide and in addition to PPC coating options in any RAL colour, various brushed, anodised, embossed and textured finishes are also available, including Rimex.

Strength, durability and colour choice are also features of the ’Polyma’ GRP range. This manufacturing process allows a high degree of design flexibility with shape; size and colour options all open to specification to meet bespoke project requirements, as well as standard profile options.

The versatility of ’Forma’ and ’Polyma’ makes them a common choice for retail projects and the high degree of freedom they offer enables major brands to specify colours that not only adhere to their brand guidelines, but also add to the customer experience.

However, where casings are needed for interior use only, the company's ’Circa’ and ’Quadra’ casings allow circular, square and rectangular profiles to be specified while also providing a wide range of finish options with the most popular being decorative laminated finishes. In addition to resisting damage, scuffs and scratches, they also provide the specifier with a diverse palette of finishes including plain colours, wood grains and metallics, as well as textured and real wood veneers.

Alongside the company’s column casings, its ’Vecta’ system provides a high quality solution for interior wall linings, bulkheads and reveals and is widely used in supermarkets, automotive retail, restaurant and food brands including Tesco, Prêt a Manger, Mini and Greggs.

Encasement’s Managing Director, Martin Taylor, explained: “By offering six different column casing ranges and the ’Vecta’ decorative wall linings system, specifiers are able to source a range of specialised interior finish products from a single company, supported by high levels of experience in this sector.”

He added: “Column casings provide a perfect mix of practicality and aesthetics and we’ve taken a lot of care to ensure our range meets both of these key criteria. We also have our own contracting arm, which enables us to offer a full supply and install service to support contractors”

This combination of practicality, versatility and decorative design has been at the centre of the wide range of retail projects that have been undertaken by Peterborough based casing solutions specialist, Encasement Ltd.

For almost 15 years, the company has been manufacturing and supplying column casing and wall lining solutions to a diverse range of retailers covering the grocery sector, home-wares, clothing, furniture stores, restaurants and automotive dealerships

As Encasement’s range provides architects, specifiers and designers with a wide choice of materials and finishes to choose from, as well as bespoke shapes and dimensions, it’s unsurprising that its products are used by many well known brands, including Debenhams, Porsche, Kia Motors, Tesco, ASDA, Oak Furnitureland and Greggs, as well as major retail parks and shopping centres across the UK.

Encasement’s column casings range includes ’Circa’ and ’Quadra’, which are manufactured from pre-formed plywood, together with the metal ’Forma’ range, ’Polyma’ and ’Gypra’ casings, which are moulded respectively from glass reinforced plastic (GRP) and glass reinforced gypsum (GRG).

In addition, the ’Metza’ range is a specialised solution that provides up to 2 hours fire protection. Originally designed for mezzanine support columns, Metza is also used in food retail fitted with corner protectors to resist scuffing and damage caused by shopping trolleys.

While every Encasement column casings is suitable for interior use, its ’Polyma’ and ’Forma’ ranges are also widely used for exterior retail projects, due to their inherent weather resistance and durability.

Available in aluminium or stainless steel, ’Forma’ casings offer a diverse range of options and can be specified as circles with diameters from 250mm up to 1000mm and in square, rectangular or hexagonal forms, as well as unique custom profiles. The choice of finishes is also very wide and in addition to PPC coating options in any RAL colour, various brushed, anodised, embossed and textured finishes are also available, including Rimex.

Strength, durability and colour choice are also features of the ’Polyma’ GRP range. This manufacturing process allows a high degree of design flexibility with shape; size and colour options all open to specification to meet bespoke project requirements, as well as standard profile options.

The versatility of ’Forma’ and ’Polyma’ makes them a common choice for retail projects and the high degree of freedom they offer enables major brands to specify colours that not only adhere to their brand guidelines, but also add to the customer experience.

However, where casings are needed for interior use only, the company's ’Circa’ and ’Quadra’ casings allow circular, square and rectangular profiles to be specified while also providing a wide range of finish options with the most popular being decorative laminated finishes. In addition to resisting damage, scuffs and scratches, they also provide the specifier with a diverse palette of finishes including plain colours, wood grains and metallics, as well as textured and real wood veneers.

Alongside the company’s column casings, its ’Vecta’ system provides a high quality solution for interior wall linings, bulkheads and reveals and is widely used in supermarkets, automotive retail, restaurant and food brands including Tesco, Prêt a Manger, Mini and Greggs.

Encasement’s Managing Director, Martin Taylor, explained: “By offering six different column casing ranges and the ’Vecta’ decorative wall linings system, specifiers are able to source a range of specialised interior finish products from a single company, supported by high levels of experience in this sector.”

He added: “Column casings provide a perfect mix of practicality and aesthetics and we’ve taken a lot of care to ensure our range meets both of these key criteria. We also have our own contracting arm, which enables us to offer a full supply and install service to support contractors”

More than four kilometres of ‘Versa 5’ pre-formed plywood fire sprinkler boxing from Encasement is being used to provide an aesthetic finish to the installation of new fire sprinkler systems at three Liberty Heights student accommodation blocks in Wolverhampton.

Operated by the UK’s second largest student accommodation provider, Liberty Living, the three blocks, one of which is 25 storeys high, provide 657 beds for students attending the nearby University of Wolverhampton and City of Wolverhampton College.

The fire sprinkler system protects corridors, kitchens, lift lobbies and public areas, in addition to the individual student rooms, and the installation was undertaken as part of an accommodation refurbishment and improvement programme by Liberty Living after acquiring the properties in early 2017.

Encasement’s pre-formed fire sprinkler boxing was chosen by the contractor as it provided a cost effective and easy to install solution to conceal the thousands of metres of orange sprinkler pipework while also providing an aesthetic finish, as the boxing is pre-finished with white melamine.

Three different sizes of 5mm thick Versa ‘L’ shaped sprinkler boxing was used on the project, as well as dedicated accessories, such as internal and external corners, to ensure that the finish to the entire sprinkler system was consistent and integrated with the building décor in each of the blocks.

To accommodate the sprinkler heads, the Versa boxing is designed to be drilled easily on-site, so that the position of the individual heads can be aligned accurately and the white cover caps can be fitted to complete the installation.

Martin Taylor, Encasement’s Managing Director, explained: “Fire safety and protection in multi-storey residential blocks is clearly a priority for many local authorities, housing associations and specialist student accommodation providers and the installation of fire sprinkler systems is an essential part of this process. We have more than 40 years experience in manufacturing and supplying pre-formed pipe boxing and decorative casings, which have been installed in countless UK and overseas projects. I’m delighted that we were chosen for Liberty Heights, which has proven to be so successful and we are currently involved in a large number of other fire sprinkler projects in social and private housing.”

www.encasement.co.uk

Operated by the UK’s second largest student accommodation provider, Liberty Living, the three blocks, one of which is 25 storeys high, provide 657 beds for students attending the nearby University of Wolverhampton and City of Wolverhampton College.

The fire sprinkler system protects corridors, kitchens, lift lobbies and public areas, in addition to the individual student rooms, and the installation was undertaken as part of an accommodation refurbishment and improvement programme by Liberty Living after acquiring the properties in early 2017.

Encasement’s pre-formed fire sprinkler boxing was chosen by the contractor as it provided a cost effective and easy to install solution to conceal the thousands of metres of orange sprinkler pipework while also providing an aesthetic finish, as the boxing is pre-finished with white melamine.

Three different sizes of 5mm thick Versa ‘L’ shaped sprinkler boxing was used on the project, as well as dedicated accessories, such as internal and external corners, to ensure that the finish to the entire sprinkler system was consistent and integrated with the building décor in each of the blocks.

To accommodate the sprinkler heads, the Versa boxing is designed to be drilled easily on-site, so that the position of the individual heads can be aligned accurately and the white cover caps can be fitted to complete the installation.

Martin Taylor, Encasement’s Managing Director, explained: “Fire safety and protection in multi-storey residential blocks is clearly a priority for many local authorities, housing associations and specialist student accommodation providers and the installation of fire sprinkler systems is an essential part of this process. We have more than 40 years experience in manufacturing and supplying pre-formed pipe boxing and decorative casings, which have been installed in countless UK and overseas projects. I’m delighted that we were chosen for Liberty Heights, which has proven to be so successful and we are currently involved in a large number of other fire sprinkler projects in social and private housing.”

www.encasement.co.uk

Saint Richard Reynolds Catholic College in Twickenham is using Encasement’s ‘Forma’ and ‘Vecta’ decorative metal casings to conceal structural steelwork around a new courtyard walkway, as part of its recently opened £14 million teaching block.