Address

Broadwell Road

Oldbury

West Midlands

UK

B69 4HF

Opening Hours

Today

Closed

View All Hours

Sunday

Closed

Monday

08:30-17:00

Tuesday

08:30-17:00

Wednesday

08:30-17:00

Thursday

08:30-17:00

Friday

08:30-13:30

Saturday

Closed

About voestalpine Metsec

voestalpine Metsec plc is the UK’s largest specialist cold roll-forming company providing products for the UK construction and manufacturing industries. We focus on adding value through expert design, precision manufacturing and on-time in full product delivery.

Established for over 90 years, Metsec plc is owned by the voestalpine group, one of Europe's leading specialist engineering companies. We are part of voestalpine’s Profilform division, the world’s largest manufacturer of cold roll-formed sections with a global network in the UK, Austria, Belgium, Czech Republic, France, Germany, Russia and the USA producing in excess of 800,000 tonnes per annum.

Building Products

• Custom Roll Forming

• Steel Framing

• Metframe

• Purlins & Side Rails

• Cable Management

• Dry Lining

Purlin Division

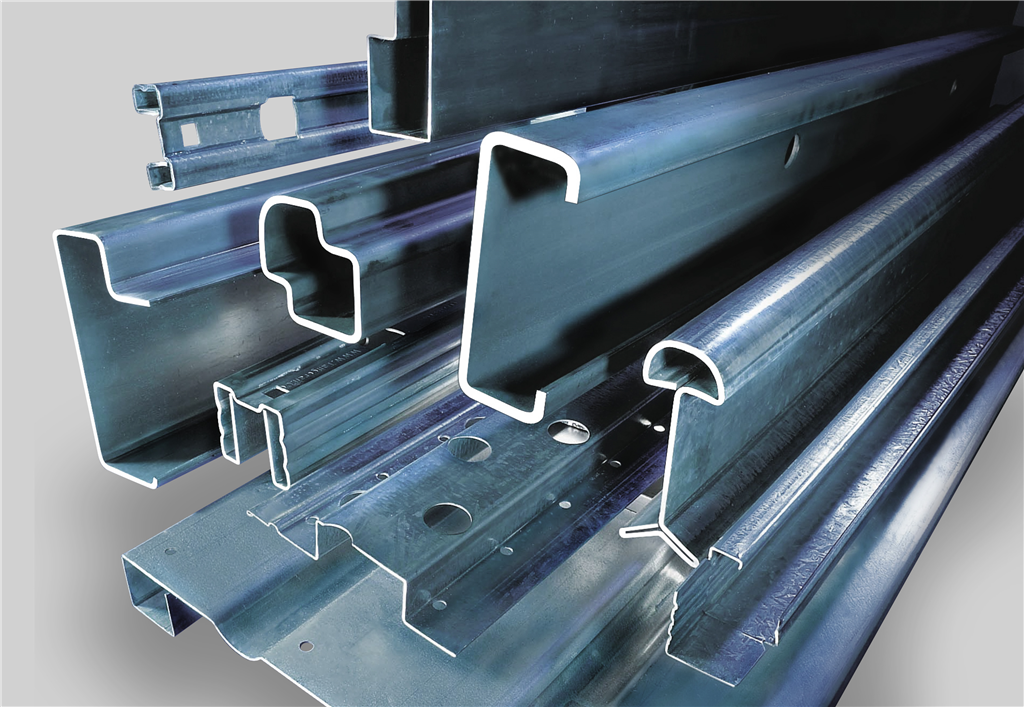

Metsec’s Purlin Division is the UK’s largest designer and manufacturer of light gauge galvanised steel purlins, side rails and mezzanine floor systems for use in a wide range of industrial and commercial developments.

• Lightweight, cold-rolled galvanised steel purlins

• Each section individually UKCA/CE marked

• Able to be designed to bespoke customer requirements

• All products are barcoded which allows for traceability throughout the manufacturing process

• Our market-leading MetSPEC 14 design software provides cost effective solutions to maximise the design efficiency of structures

• Suitable for a wide range of developments

Framing Division

Metsec’s Framing Division developed and now leads the market when it comes to light gauge, galvanised steel structural framing systems suitable for a wide range of applications in most sectors of construction.

Our two systems are Metframe – a pre-panelised framing system that is fabricated off-site and assembled on-site with concrete floors providing complete superstructures and SFS - a fast track steel stud panel frame which is fixed as infill between the main structural frame members and provides a carrier for insulation, exterior cladding and interior wallboard. Both systems offer pre-engineered off-site fabrication in line with the demands of Modern Methods of Construction and are structurally proven and independently tested to provide thermal, acoustic and fire resistance.

Metframe Division

voestalpine Metsec are leading steel frame manufacturers offering innovative construction solutions to countries across the globe. Metframe is our pre-panelised, off-site framing solution.

Metframe benefits include:

• Faster build time compared to traditional methods

• Rapid installation

• BIM Level 2 compliant

• Zero waste

• High thermal, fire and acoustic performance

• Complex structures are easily incorporated

• Independent and accredited Edge Protection system

• Suitable for use with a variety of external finishes

• NHBC/SCI approval for up to 15 storeys

• Manufactured in a controlled factory environment

• FORS accredited for HGV Metsec deliveries

• Design warranty and 30 year MetWALL Perform warranty

• Suitable for tight construction spaces

• Suitable for all types of sectors inc. care homes, student accommodation, residential, hotels, education and more.

Custom Roll Forming

Custom Roll Forming at Metsec provides bespoke standard metal profiles and special welded tubes in gauges from 0.5mm up to 6mm thick. These tailor-made profiles can be manufactured from steel, aluminium, copper, brass, stainless steel and even pre-painted material.

Another advantage of roll forming is that stress caused when bending materials too quickly can be avoided. From the initial roll tooling design the process undergoes a full Finite Element Analysis to ensure that the product is produced exactly to our customers design without inherent weaknesses. Overall the reduction of unwanted material stresses can be avoided by intelligent design and the gradual continuous forming process.

Cable Management

Metsec Cable Management manufactures cable containment and support systems for the mechanical and electrical services industry.

voestalpine Metsec plc Cable Management are complete systems with simple accessories, offering flexible design solutions and the rapid installation system. A prefabrication service is also available for major contracts, bringing significant time and cost savings for M & E contractors.

Dry Lining

Metsec Dry Lining specialise in the manufacture and supply of light gauge, non-load bearing, cold-rolled formed metal products for use in partitioning, dry lining and ceiling systems. We supply our strategic partners, a network of major distributors, where our products are frequently own branded.

Our dry lining systems are fully and independently tested in UKAS accredited laboratories with proprietary gypsum products . providing reassurance that our products can be specified to meet statutory requirements.

Gallery

Videos

News

Light gauge galvanised steel framing systems (SFS) are primarily used for wall constructions, such as infill walling, continuous walling, high bay walling and loadbearing structures in low to medium rise situations.

Their light weight and versatility deliver benefits to the entire construction team, providing the designer, developer and end client with cost-efficient, sustainable design solutions for a wide variety of residential, hotel, student accommodation, social housing, healthcare and education projects.

Whilst efficiency, versatility and sustainability are desirable attributes for any building system, they count for little without certified proof of the system’s ability to meet the required technical performance standards in the areas of acoustics, thermal efficiency, loadbearing and, most importantly, fire protection.

With steel framing systems, fire performance and thermal efficiency are achieved through the combination of materials that are used in conjunction with SFS to construct the wall. For external wall constructions, from inside to out, this would typically consist of dry lining, SFS (possibly including insulation within), sheathing board and insulation. The final wall construction can vary according to the external façade materials that are used, which can range from brickwork to insulated render, timber cladding, composite panels, ventilated rainscreen and many others that might be selected to achieve the desired exterior finish or budget.

Traditionally, performance of the wall construction could be assessed by compiling the technical data from manufacturers of each of the materials used in the construction; boards, sheathing, SFS and insulation. Whilst building materials manufacturers were confident that their products would work within a system of suitable products, since Grenfell, there has been increasing recognition amongst SFS manufacturers of the need to undertake fire testing of the wall construction itself to provide a ‘through wall’ performance, providing designers and contractors with added assurance of a solution’s performance capabilities.

Whilst there is currently no strict definition of what ‘through wall’ means, it is widely regarded as the part of the wall that provides the majority of the fire, thermal and acoustic properties, most commonly the zone from the inside face of the internal dry lining to the outside face of either the sheathing board or insulation.

The reason for this ‘through wall’ concept is that, with so many exterior façade materials available, it would be impossible to test every possible wall construction. The ‘through wall’ approach to performance allows manufacturers to test a meaningful number of material combinations (SFS, internal and external boards plus insulation). The tested solutions will either be from the dry lining through to the sheathing board or from the dry lining to external insulation.

This approach provides the design team with the freedom to choose the desired external façade, provided, of course, that the necessary performance requirements are met.

Building regulations set out requirements for time performance, particularly with regard to integrity (passage of smoke and flame), insulation (temperature on the opposite side of the wall) and load bearing capacity where the wall is being used in a structural capacity.

In order to achieve ‘through wall’ fire performance data, SFS manufacturers construct different complete wall build-ups measuring 3m x 3m, comprising light gauge steel frames fitted with various combinations of boards and insulation materials to UKAS-accredited laboratories for testing.

Each build-up is tested using a large scale, high heat test (reaching up to 600 degrees Centigrade in 5 minutes), which measures the performance of the whole wall by simulating fire trying to break out through a solid wall. Tests are conducted to British Standards BS EN 1364-1 and BS 476-22 (for non-loadbearing walls) to achieve the 120-minute, 60-minute and 30-minute fire ratings typically required by building regulations.

In most cases, fire performance is an inside to out requirement, aiming to prevent the spread of fire from its source to adjacent compartments. However, where buildings are in close proximity to each other fire resistance will also be required from outside to in.

Whatever the circumstances, through wall fire testing and the performance data it returns for the combinations of materials used in wall constructions is a positive step forward from SFS manufacturers. As more manufacturers commit to this approach, the array of certified wall constructions available to designers will increase (at Metsec, we currently offer more than 400 configurations), providing greater choice and flexibility in the solutions they can use, not only to meet fire performance requirements but also to achieve other performance criteria, such as thermal and acoustic insulation, as well as satisfying aesthetic and

Their light weight and versatility deliver benefits to the entire construction team, providing the designer, developer and end client with cost-efficient, sustainable design solutions for a wide variety of residential, hotel, student accommodation, social housing, healthcare and education projects.

Whilst efficiency, versatility and sustainability are desirable attributes for any building system, they count for little without certified proof of the system’s ability to meet the required technical performance standards in the areas of acoustics, thermal efficiency, loadbearing and, most importantly, fire protection.

With steel framing systems, fire performance and thermal efficiency are achieved through the combination of materials that are used in conjunction with SFS to construct the wall. For external wall constructions, from inside to out, this would typically consist of dry lining, SFS (possibly including insulation within), sheathing board and insulation. The final wall construction can vary according to the external façade materials that are used, which can range from brickwork to insulated render, timber cladding, composite panels, ventilated rainscreen and many others that might be selected to achieve the desired exterior finish or budget.

Traditionally, performance of the wall construction could be assessed by compiling the technical data from manufacturers of each of the materials used in the construction; boards, sheathing, SFS and insulation. Whilst building materials manufacturers were confident that their products would work within a system of suitable products, since Grenfell, there has been increasing recognition amongst SFS manufacturers of the need to undertake fire testing of the wall construction itself to provide a ‘through wall’ performance, providing designers and contractors with added assurance of a solution’s performance capabilities.

Whilst there is currently no strict definition of what ‘through wall’ means, it is widely regarded as the part of the wall that provides the majority of the fire, thermal and acoustic properties, most commonly the zone from the inside face of the internal dry lining to the outside face of either the sheathing board or insulation.

The reason for this ‘through wall’ concept is that, with so many exterior façade materials available, it would be impossible to test every possible wall construction. The ‘through wall’ approach to performance allows manufacturers to test a meaningful number of material combinations (SFS, internal and external boards plus insulation). The tested solutions will either be from the dry lining through to the sheathing board or from the dry lining to external insulation.

This approach provides the design team with the freedom to choose the desired external façade, provided, of course, that the necessary performance requirements are met.

Building regulations set out requirements for time performance, particularly with regard to integrity (passage of smoke and flame), insulation (temperature on the opposite side of the wall) and load bearing capacity where the wall is being used in a structural capacity.

In order to achieve ‘through wall’ fire performance data, SFS manufacturers construct different complete wall build-ups measuring 3m x 3m, comprising light gauge steel frames fitted with various combinations of boards and insulation materials to UKAS-accredited laboratories for testing.

Each build-up is tested using a large scale, high heat test (reaching up to 600 degrees Centigrade in 5 minutes), which measures the performance of the whole wall by simulating fire trying to break out through a solid wall. Tests are conducted to British Standards BS EN 1364-1 and BS 476-22 (for non-loadbearing walls) to achieve the 120-minute, 60-minute and 30-minute fire ratings typically required by building regulations.

In most cases, fire performance is an inside to out requirement, aiming to prevent the spread of fire from its source to adjacent compartments. However, where buildings are in close proximity to each other fire resistance will also be required from outside to in.

Whatever the circumstances, through wall fire testing and the performance data it returns for the combinations of materials used in wall constructions is a positive step forward from SFS manufacturers. As more manufacturers commit to this approach, the array of certified wall constructions available to designers will increase (at Metsec, we currently offer more than 400 configurations), providing greater choice and flexibility in the solutions they can use, not only to meet fire performance requirements but also to achieve other performance criteria, such as thermal and acoustic insulation, as well as satisfying aesthetic and

The construction of one of Scotland’s largest school and community projects has made extensive use of Metsec’s SFS lightweight steel framing system to deliver time and cost savings.

The £55 million project sees the creation of brand-new education and sports facilities in the centre of Inverurie which will provide a hub for academic study and community activities in the Aberdeenshire town.

The new Inverurie Community Campus includes state-of-the-art teaching accommodation for up to 1,600 pupils as well as extensive sports and leisure facilities for locals, including a six-lane swimming pool, hydrotherapy pool, sports hall, fitness suite, dancing studio and community café.

The project has been undertaken by Aberdeenshire Council through developers Hub North Scotland. Halliday Fraser Munro were principal designers for the project, with construction being awarded to the Robertson Group.

Metsec-approved installers, Veitchi Interiors were successful in tendering for the continuous walling that would form the external envelopes of the academy and community buildings, which extended to three storeys in height and are finished in a combination of brickwork and cladding. Some 20,000 metres of SFS was used as infill between the hot-rolled structural steel frame.

SFS proved to be the perfect solution for the campus buildings as Donald Turner, director at Veitchi Interiors, explains, “SFS was the ideal choice for the design and scope of this project. The ability to combine SFS with other construction methods meant that it dovetailed nicely with the hot-rolled steel frame, whilst Metsec’s technical department worked closely with the project’s structural engineers, Fairhurst, to prepare the necessary designs. Further close liaison with Veitchi and the construction team meant that planning, scheduling and delivery of the SFS components to site was precise and timely.

“Installation of SFS is quick and easy. Once installed and boarded it provides immediate protection from the elements, enabling follow-on trades to start their work at a very early stage and allowing the project to progress quickly and smoothly.”

Opened in the Autumn of 2020, Inverurie Community Campus has drawn praise from politicians, councillors and the community as a whole, winning the Development of the Year (Public buildings) at the 2021 Scottish Property Awards.

The £55 million project sees the creation of brand-new education and sports facilities in the centre of Inverurie which will provide a hub for academic study and community activities in the Aberdeenshire town.

The new Inverurie Community Campus includes state-of-the-art teaching accommodation for up to 1,600 pupils as well as extensive sports and leisure facilities for locals, including a six-lane swimming pool, hydrotherapy pool, sports hall, fitness suite, dancing studio and community café.

The project has been undertaken by Aberdeenshire Council through developers Hub North Scotland. Halliday Fraser Munro were principal designers for the project, with construction being awarded to the Robertson Group.

Metsec-approved installers, Veitchi Interiors were successful in tendering for the continuous walling that would form the external envelopes of the academy and community buildings, which extended to three storeys in height and are finished in a combination of brickwork and cladding. Some 20,000 metres of SFS was used as infill between the hot-rolled structural steel frame.

SFS proved to be the perfect solution for the campus buildings as Donald Turner, director at Veitchi Interiors, explains, “SFS was the ideal choice for the design and scope of this project. The ability to combine SFS with other construction methods meant that it dovetailed nicely with the hot-rolled steel frame, whilst Metsec’s technical department worked closely with the project’s structural engineers, Fairhurst, to prepare the necessary designs. Further close liaison with Veitchi and the construction team meant that planning, scheduling and delivery of the SFS components to site was precise and timely.

“Installation of SFS is quick and easy. Once installed and boarded it provides immediate protection from the elements, enabling follow-on trades to start their work at a very early stage and allowing the project to progress quickly and smoothly.”

Opened in the Autumn of 2020, Inverurie Community Campus has drawn praise from politicians, councillors and the community as a whole, winning the Development of the Year (Public buildings) at the 2021 Scottish Property Awards.

Metsec’s lightweight steel framing system, SFS, is being used in the creation of a new £346m riverside residential development in the Barking and Dagenham area of London, which will eventually provide more than 900 new homes for the capital.

Fresh Wharf is being developed by Countryside, the UK’s leading mixed-tenure developer, in partnership with housing association Notting Hill Genesis on a 10-acre, former brownfield site situated along the banks of the River Roding, a tributary of the River Thames.

The site was previously used for commercial lettings before being acquired by Countryside. Demolition of old premises on the site started in early 2018 and Phase 1 of the two-phase construction project commenced later that year.

Working with architects and urban planners, Metropolitan Workshop, Countryside and Notting Hill Genesis have created a scheme which is designed to maximise the benefits of the river frontage and city views.

In addition to a mix of contemporary one to three-bedroom apartments together with three-bedroom townhouses, Fresh Wharf will feature a large, open park at its centre and three landscape-led public realm areas. Existing boat moorings will be reinstated and a selection of shops, cafes and restaurants will be incorporated in the development’s Northern Square, adding to the vibrancy of the area.

Phase 1 of the project sees the construction of 532 homes, accommodated in five apartment blocks of between five and fifteen storeys and ten three-storey townhouses.

Following the demolition works, Countryside needed to raise the level of the riverside site for protection against flooding. This was achieved by capping to achieve a finished floor level of 6.30m AOD.

After this, construction of the new properties commenced in earnest, with the apartment blocks and townhouses being constructed from concrete frames. It is here that Metsec’s lightweight steel framing system, SFS came into play, providing infill for the properties.

Almost 16,000m2 of 100mm SFS was supplied as infill for the external brickwork facades of the apartments and townhouses. To assure compliance with NHBC moisture control requirements, SFS sections being used in areas such as the ground floor, balconies and roof terraces were manufactured from Z600 galvanised steel to provide added protection.

Installation was undertaken by specialist sub-contractor, Stanmore, with Metsec using Revit to create the construction level design for the framing system at the early stages of the project’s conceptualisation.

Garry Tarvet, Associate Technical Director, Partnerships East London, Countryside, comments, “Engaging with Metsec’s team at the very early stages of the project de-risked the design process for us. It ensured that the project could progress smoothly and avoided disruption of the design and construction processes, allowing us to meet our timetable.

“Metsec’s BIM and 3D modelling capabilities also allows them to integrate their designs with our own models, further streamlining the process and making the project much easier to manage from start to finish.”

Working with Metropolitan Workshop, Countryside has also taken a great deal of care to avoid Fresh Wharf being a standard frame and cladding development. External aesthetics have been assured by attention to detail in the selection and detailing of the brickwork, which includes sawtooth brick, basketweave details and multi-course soldiering to add variety, interest and quality to the final finish.

Fresh Wharf is being developed by Countryside, the UK’s leading mixed-tenure developer, in partnership with housing association Notting Hill Genesis on a 10-acre, former brownfield site situated along the banks of the River Roding, a tributary of the River Thames.

The site was previously used for commercial lettings before being acquired by Countryside. Demolition of old premises on the site started in early 2018 and Phase 1 of the two-phase construction project commenced later that year.

Working with architects and urban planners, Metropolitan Workshop, Countryside and Notting Hill Genesis have created a scheme which is designed to maximise the benefits of the river frontage and city views.

In addition to a mix of contemporary one to three-bedroom apartments together with three-bedroom townhouses, Fresh Wharf will feature a large, open park at its centre and three landscape-led public realm areas. Existing boat moorings will be reinstated and a selection of shops, cafes and restaurants will be incorporated in the development’s Northern Square, adding to the vibrancy of the area.

Phase 1 of the project sees the construction of 532 homes, accommodated in five apartment blocks of between five and fifteen storeys and ten three-storey townhouses.

Following the demolition works, Countryside needed to raise the level of the riverside site for protection against flooding. This was achieved by capping to achieve a finished floor level of 6.30m AOD.

After this, construction of the new properties commenced in earnest, with the apartment blocks and townhouses being constructed from concrete frames. It is here that Metsec’s lightweight steel framing system, SFS came into play, providing infill for the properties.

Almost 16,000m2 of 100mm SFS was supplied as infill for the external brickwork facades of the apartments and townhouses. To assure compliance with NHBC moisture control requirements, SFS sections being used in areas such as the ground floor, balconies and roof terraces were manufactured from Z600 galvanised steel to provide added protection.

Installation was undertaken by specialist sub-contractor, Stanmore, with Metsec using Revit to create the construction level design for the framing system at the early stages of the project’s conceptualisation.

Garry Tarvet, Associate Technical Director, Partnerships East London, Countryside, comments, “Engaging with Metsec’s team at the very early stages of the project de-risked the design process for us. It ensured that the project could progress smoothly and avoided disruption of the design and construction processes, allowing us to meet our timetable.

“Metsec’s BIM and 3D modelling capabilities also allows them to integrate their designs with our own models, further streamlining the process and making the project much easier to manage from start to finish.”

Working with Metropolitan Workshop, Countryside has also taken a great deal of care to avoid Fresh Wharf being a standard frame and cladding development. External aesthetics have been assured by attention to detail in the selection and detailing of the brickwork, which includes sawtooth brick, basketweave details and multi-course soldiering to add variety, interest and quality to the final finish.

UK

UK Ireland

Ireland Scotland

Scotland London

London