Telephone

Click to view

Fax

0191 455 4443

Contact

Richard Bailey

Email

Address

Unit 1B North East Foundry

Templetown

Templetown

South Shields

Tyne and Wear

NE33 5SE

About Structural Timber Systems Ltd

Structural Timber Systems Ltd is evolving as a company to meet the demands of the modern eco-conscious customer who requires state of the art technology without making the substantial impact on the environment that traditional methods of construction usually incur.

What We Stand For:

Design

Our experienced design team use state of the art software to create 3D visualisations of what is to be manufactured for all of our products.

Types Of Projects

At Structural Timber Systems we know that off-site construction is the most efficient and economic way of timber frame building construction so we try to do everything that we can in our factory in South Shields.

Off Site Manufacture

We mainly carry out full timber frame house manufacture for one-of self-builders who require the whole building package.

Timber Frames

Structural timber frame construction in its most basic form has been a construction method for many years. Though this will still be the case for years to come, the increasing demands from the government to reduce the amount of Carbon Dioxide emitted from new buildings is placing a large amount of pressure on companies like ourselves to make sure our clients meet these strict requirements.

The details of the timber frame kits we provide are as follows:

Floor Joists

We use and specify Ecojoists due to their practical benefits, low environmental impact and dimensional versatility. We encourage all of our clients to use this technology within their buildings because of the points highlighted below.

Roof trusses are the predominant method of roof construction in all sectors of the industry.

Their benefits are highlighted in the points below:

What We Stand For:

- We aim to make as little impact on the environment in all aspects of our work.

- Experienced workforce from architectural, engineering and site construction backgrounds.

- We pride ourselves on repeat business from companies who are happy with our work.

- Our experience, commitment and excellent customer service is prevalent in a very competitive industry.

- We make sure to use only the most sustainable materials from sustainable sources.

- Our products are manufactured using materials optimised by our state of the art timber frame, roof and joist software to eliminate site waste.

- Efficient bulk delivery service to reduce our ‘carbon footprint’.

- We keep up to date with new and innovative technologies.

We Work With:

- Developers

- Social Housing

- Self Build

- Education

- Healthcare

We Make:

- Timber Frame

- Roof Trusses

- Floor Joists

- Feature roof Trusses

Design

Our experienced design team use state of the art software to create 3D visualisations of what is to be manufactured for all of our products.

Types Of Projects

At Structural Timber Systems we know that off-site construction is the most efficient and economic way of timber frame building construction so we try to do everything that we can in our factory in South Shields.

Off Site Manufacture

We mainly carry out full timber frame house manufacture for one-of self-builders who require the whole building package.

Timber Frames

Structural timber frame construction in its most basic form has been a construction method for many years. Though this will still be the case for years to come, the increasing demands from the government to reduce the amount of Carbon Dioxide emitted from new buildings is placing a large amount of pressure on companies like ourselves to make sure our clients meet these strict requirements.

The details of the timber frame kits we provide are as follows:

- Designed in state of the art timber frame software by experienced designers.

- Designed to Robust Standard Details where required.

- We use and encourage innovative technologies.

- Various levels of timber frame kit specification related to client requirements.

- Fully insulated ‘closed’ panels possible.

- We can provide floor joists and roof joists/trusses in both loose and cassette form.

- Highly skilled team of timber frame kit erectors.

- All timber is double vacuum treated to eliminate site degradation.

- All timber is provided to CLS (Canadian Lumber Standards) sizes for dimensional consistency and manufacturing/installation accuracy.

- Delivery and installation anywhere in the United Kingdom.

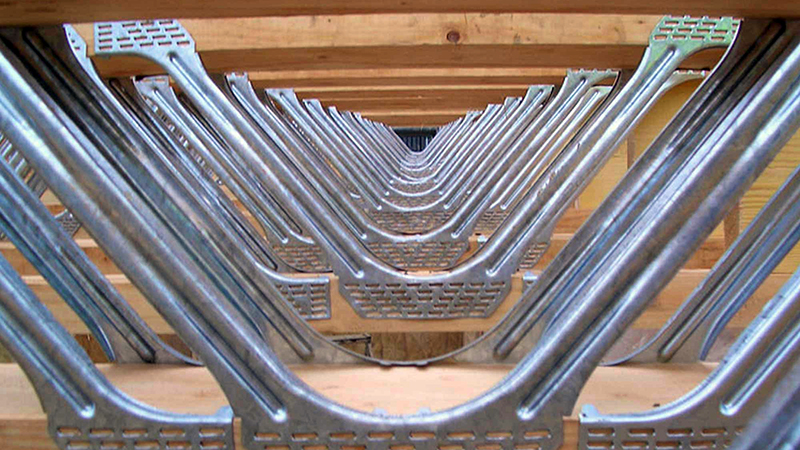

Floor Joists

We use and specify Ecojoists due to their practical benefits, low environmental impact and dimensional versatility. We encourage all of our clients to use this technology within their buildings because of the points highlighted below.

- Designed in house using specialist software.

- Manufactured in house for greater efficiency.

- Open web system allows uninterrupted access for services.

- 72-122mm flanges provide a large area for fixing of floor decking.

- Large spans easily achieved.

- Depth compatible with solid joist sizes.

- We can provide floor joists and roof joists/trusses in both loose and cassette form.

- Made to measure, reducing site wastage.

- Minimal shrinkage or swelling.

- Reduction or elimination of surface run pipework.

- Lightweight construction.

- Erected in half the time of conventional joists.

- Can be top chord supported.

- We can provide ‘I’ Beam joists from the large range of manufacturers and also solid timber floor joists if specifically required.

Roof trusses are the predominant method of roof construction in all sectors of the industry.

Their benefits are highlighted in the points below:

- Designed in house using specialist software.

- Manufactured in house.

- No site wastage.

- Speed of construction.

- Dimensional accuracy (+/- 5mm).

- Most structural shapes can be designed and constructed.

- Various profiles of roof trusses possible.

- Full set of structural calculations with each set of trusses provided.

UK

UK Ireland

Ireland Scotland

Scotland London

London