Telephone

Click to view

Mobile

Click to view

Website

Contact

Michael Plimmer

Email

Address

Lakeside House Lancaster Park

Newborough Road

Newborough Road

Burton-on-Trent

Staffordshire

DE13 9PD

England

About Panelpro

The home of high quality vinyl pressed panels & more

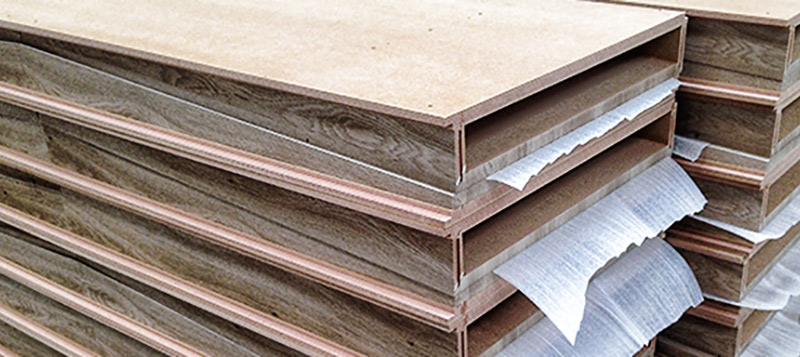

Established in 1970 as cabinet makers, Panelpro now manufacture high quality vinyl 3D pressed MDF panels as well as cut and edged MFC panels, High Gloss Acrylic doors and supply to many sectors of the furniture market. We are a premier producer of High Gloss doors and also supply panels for exhibitions, walling, office furniture, counter displays and hi fi products.

We offer 3D pressing of Kydex® to MDF which offers a more robust and wear resistant finish, ideal for busy commercial areas and shop fitting. We are experienced in every aspect of furniture door and panel production offering Pressed, cut, edged, drilled and CNC machined panels in a vaiety of materials. We can assemble components that are produced in our machine shops, thereby offering a total in-house solution.

We can help you with the design and realisation and final ongoing production of your product as all processes are carried out in house; we do not outsource any work. In 2008, we moved to our new custom built factory designed by us, having more space at our disposal, means we can now undertake larger projects and store products more easily. As a family business we strive harder for our customers and are confident that we can assist you with the design and manufacture of your project, and bring it to fruition exactly as conceived within your budget. Contact us today in the knowledge you can be sure that we really will make things better for you.

Services

Our Mantra is quality and service. We are friendly and easy to deal with and make things better for you. This means you get all what you want when you need it.

What We Provide

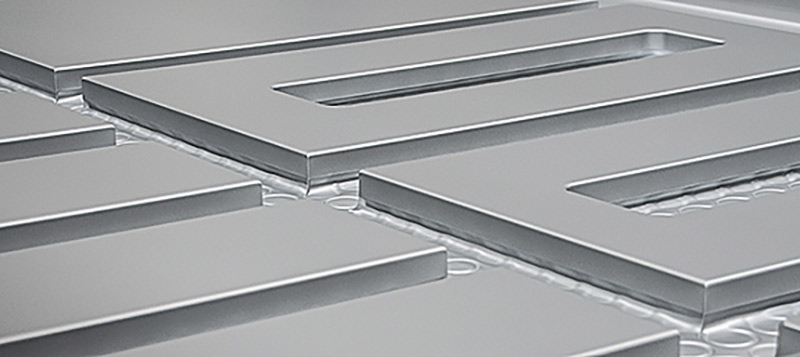

Panelpro is a premier High Gloss Door manufacturer and produces the very best MDF high gloss doors available in the UK. We also produce matt colours and a variety of woodgrains.

Kydex is another plastic sheet material that we use. This material is extremely durable and is used extensively in the aircraft industry, so it's excellent for use in the shop fitting and display markets. Our main production is based around membrane pressing and machining wood based panels, using MDF, MFC, Chipboard, Compact Laminate and Plywood. Various plastics are also used.

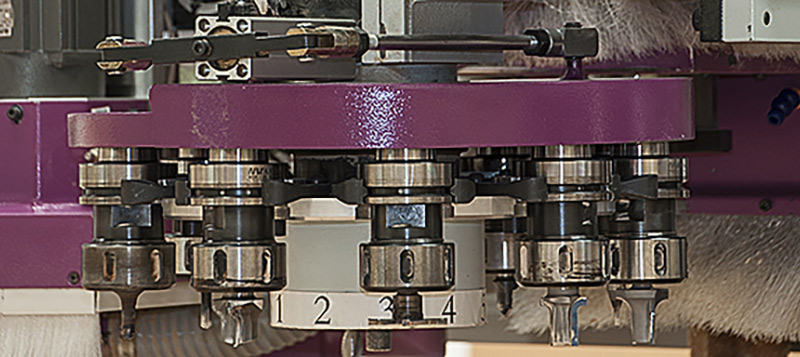

We also provide machining services which includes cut to size, CNC routed, drilled, grooved, and sanded panels. The use of modern machinery and the latest technology guarantees that your panels are made to the correct size, shape and tolerance.

Product Development - Vinyl Doors, Wall Panelling And Much More

We create what you need when you need it, involving us early will benefit your product both aesthetically and financially. Value engineering and our experience will save you time and money without compromising on quality. It is important that the most efficient manufacturing methods are applied at the beginning of a project, coming to us sooner will greatly benefit your project or product. Make us your first port of call.

Vinyl Wrapped MDF, MFC & Plywood Panel Processing

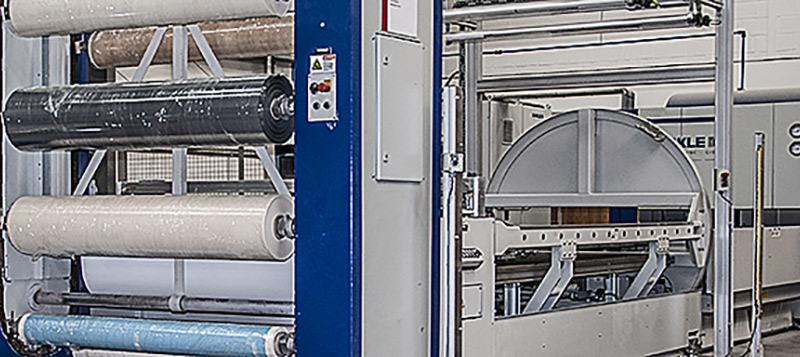

Our machine shop is equiped with the very latest CNC machinery. Any panels can be accurately sawn or machined to size, profiled, grooved and drilled using our twin table routers, single table router or for boring only, on our through feed CNC boring machine. We offering 3D forming of decorative vinyl or KYDEX onto MDF.

Ongoing continuous length drilling of panels can be carried out up to a maximum width of 800mm on our through feed CNC boring machine with no lenght limitation or than the material size available.

We offer 'V' Grooving of MDF vinyl laminated panels, where a 90 degree 'V'.is formed on a panel without braking through the veneer. This allows the panel to fold to an angle of 90 degrees with no visible joint to be seen. This process is know as 'Mitre-folding' and can be extremely useful in folding the panel to form a box or cabinet without the use of edging material. Other angles can be formed in this way to provide hexagonal or octagonal shapes which can be used for enclosing steel column structures. There are many other uses for this process especially for display applications and shopfitting.

Assembly – Getting It Together

We are able to offer in-house assembly for many furniture panel products and assemblies. These can include sub, part or complete assembly of your product. Sub-assembly can take the form of electrical component fitting of lighting, power points, cable looms, hardware, brackets, and KD fittings as well as metal or plastic threaded inserts.

Complete assemble items include cooker hoods, furniture carcases and visual display products for shops. Barcode labelling can be applied in order to identify each product. If you have a project that requires any assembly please contact us today, we would be pleased to hear from you.

Established in 1970 as cabinet makers, Panelpro now manufacture high quality vinyl 3D pressed MDF panels as well as cut and edged MFC panels, High Gloss Acrylic doors and supply to many sectors of the furniture market. We are a premier producer of High Gloss doors and also supply panels for exhibitions, walling, office furniture, counter displays and hi fi products.

We offer 3D pressing of Kydex® to MDF which offers a more robust and wear resistant finish, ideal for busy commercial areas and shop fitting. We are experienced in every aspect of furniture door and panel production offering Pressed, cut, edged, drilled and CNC machined panels in a vaiety of materials. We can assemble components that are produced in our machine shops, thereby offering a total in-house solution.

We can help you with the design and realisation and final ongoing production of your product as all processes are carried out in house; we do not outsource any work. In 2008, we moved to our new custom built factory designed by us, having more space at our disposal, means we can now undertake larger projects and store products more easily. As a family business we strive harder for our customers and are confident that we can assist you with the design and manufacture of your project, and bring it to fruition exactly as conceived within your budget. Contact us today in the knowledge you can be sure that we really will make things better for you.

Services

Our Mantra is quality and service. We are friendly and easy to deal with and make things better for you. This means you get all what you want when you need it.

What We Provide

Panelpro is a premier High Gloss Door manufacturer and produces the very best MDF high gloss doors available in the UK. We also produce matt colours and a variety of woodgrains.

Kydex is another plastic sheet material that we use. This material is extremely durable and is used extensively in the aircraft industry, so it's excellent for use in the shop fitting and display markets. Our main production is based around membrane pressing and machining wood based panels, using MDF, MFC, Chipboard, Compact Laminate and Plywood. Various plastics are also used.

We also provide machining services which includes cut to size, CNC routed, drilled, grooved, and sanded panels. The use of modern machinery and the latest technology guarantees that your panels are made to the correct size, shape and tolerance.

Product Development - Vinyl Doors, Wall Panelling And Much More

We create what you need when you need it, involving us early will benefit your product both aesthetically and financially. Value engineering and our experience will save you time and money without compromising on quality. It is important that the most efficient manufacturing methods are applied at the beginning of a project, coming to us sooner will greatly benefit your project or product. Make us your first port of call.

Vinyl Wrapped MDF, MFC & Plywood Panel Processing

Our machine shop is equiped with the very latest CNC machinery. Any panels can be accurately sawn or machined to size, profiled, grooved and drilled using our twin table routers, single table router or for boring only, on our through feed CNC boring machine. We offering 3D forming of decorative vinyl or KYDEX onto MDF.

Ongoing continuous length drilling of panels can be carried out up to a maximum width of 800mm on our through feed CNC boring machine with no lenght limitation or than the material size available.

We offer 'V' Grooving of MDF vinyl laminated panels, where a 90 degree 'V'.is formed on a panel without braking through the veneer. This allows the panel to fold to an angle of 90 degrees with no visible joint to be seen. This process is know as 'Mitre-folding' and can be extremely useful in folding the panel to form a box or cabinet without the use of edging material. Other angles can be formed in this way to provide hexagonal or octagonal shapes which can be used for enclosing steel column structures. There are many other uses for this process especially for display applications and shopfitting.

Assembly – Getting It Together

We are able to offer in-house assembly for many furniture panel products and assemblies. These can include sub, part or complete assembly of your product. Sub-assembly can take the form of electrical component fitting of lighting, power points, cable looms, hardware, brackets, and KD fittings as well as metal or plastic threaded inserts.

Complete assemble items include cooker hoods, furniture carcases and visual display products for shops. Barcode labelling can be applied in order to identify each product. If you have a project that requires any assembly please contact us today, we would be pleased to hear from you.

Panelpro.

5

out of 5

based on 3 ratings.

Reviews & Testimonials for Panelpro

We moved to our custom-built offices in Whitley, Hampshire, Panel Pro were involved in the supply of the desktops for our offices which numbered several thousand. In addition to this, they supplied Triumph Office cabinets with the drawer fronts which were made to match that of the desktops in order to provide a fluid and cohesive environment.

As part of the supply condition, a 5 year guarantee was offered which was a great ups for us to decide to commission Panel Pro for the project.

The desks have proved to be serviceable well beyond the guarantee period and have completely fulfilled our requirements, both ergonomically and aesthetically.

As part of the supply condition, a 5 year guarantee was offered which was a great ups for us to decide to commission Panel Pro for the project.

The desks have proved to be serviceable well beyond the guarantee period and have completely fulfilled our requirements, both ergonomically and aesthetically.

May 01, 2017

Testimonial by

The National Air Traffic Centre

Testimonial by

The National Air Traffic Centre

Jaguar Land Rover's Motor Show Exhibition Stands look more individual and attractive.

From a design created by Imagination of London, we were able to engineer and manufacture modular zigzag wall and shoebox style ceiling panels in a rustic golden oak finish. To achieve this we pressed the panels and then 'V' grooved and folded them into the required designed form. By using this method, no unsightly joints could be seen and continuity of the wood grain was maintained. Each individual oak veneered zigzag panel was then assembled and mounted onto a fire resistant MDF back panel to create a modular wall panel of 2.6 metres in height. Specially designed hanging brackets were manufactured and fitted to the back of the panels in order to ensure that they could be quickly and safely fitted to a pre-errected skeleton lightweight frame. The stand was installed by our customer and site contractor CDI.

We create and manufacture many types of wall panelling, some of which have 3D designs machined into the panels to give the desired effect.

From a design created by Imagination of London, we were able to engineer and manufacture modular zigzag wall and shoebox style ceiling panels in a rustic golden oak finish. To achieve this we pressed the panels and then 'V' grooved and folded them into the required designed form. By using this method, no unsightly joints could be seen and continuity of the wood grain was maintained. Each individual oak veneered zigzag panel was then assembled and mounted onto a fire resistant MDF back panel to create a modular wall panel of 2.6 metres in height. Specially designed hanging brackets were manufactured and fitted to the back of the panels in order to ensure that they could be quickly and safely fitted to a pre-errected skeleton lightweight frame. The stand was installed by our customer and site contractor CDI.

We create and manufacture many types of wall panelling, some of which have 3D designs machined into the panels to give the desired effect.

June 07, 2016

Testimonial by

JLR Motor Shows

Testimonial by

JLR Motor Shows

Creative watch and jewellery displays for leading watch brands and jewellery stores has been part of our manufacturing program for many years. Our customers have appreciated our input into many watch and jewellery displays.

Display trays within Jewellers shops have traditionally been a wooden base covered in a vinyl fabric which is glued in place. When placed in a shop window with all the lighting and heat that is generated, the fabric tends to come undone at the corners. Using our process, there is no corner joints that have to be disguised and that fail after time, which is unsightly and that has to be replaced. Our trays have not only proved to be better but in many cases also cheaper.

We have made many different jewellery trays, in some we have encapsulted invisible magnets into the MDF panel prior to pressing the vinyl in order to retain small display items on the tray. This served to retain ring or bracelet stands that have a metal base to firmly fix the them in position. This is especially important when the trays are being taken in and out of the shop window. We have also engraved a logo or created a design detail to customise the display tray.

We have made watch displays to look very effective when holding quite a number of watches by using multiple panels, in a staircase format which were arranged horizontally and vertically. When assembled this gave an attractive corporate display.

Display trays within Jewellers shops have traditionally been a wooden base covered in a vinyl fabric which is glued in place. When placed in a shop window with all the lighting and heat that is generated, the fabric tends to come undone at the corners. Using our process, there is no corner joints that have to be disguised and that fail after time, which is unsightly and that has to be replaced. Our trays have not only proved to be better but in many cases also cheaper.

We have made many different jewellery trays, in some we have encapsulted invisible magnets into the MDF panel prior to pressing the vinyl in order to retain small display items on the tray. This served to retain ring or bracelet stands that have a metal base to firmly fix the them in position. This is especially important when the trays are being taken in and out of the shop window. We have also engraved a logo or created a design detail to customise the display tray.

We have made watch displays to look very effective when holding quite a number of watches by using multiple panels, in a staircase format which were arranged horizontally and vertically. When assembled this gave an attractive corporate display.

May 03, 2016

Testimonial by

Designer Watch & Jeweller Displays.

Testimonial by

Designer Watch & Jeweller Displays.

UK

UK Ireland

Ireland Scotland

Scotland London

London