Address

50 Creagh Road

Toomebridge

Co L/Derry

BT41 3SE

Northern Ireland

About Precision Gear Company Ltd

What Can PGC Provide?

PGC would like to have a moment of your time to give you an update of our company's current capabilities and ongoing projects. PGC are active in the refurbishment of gear units ranging from 20Kw up to 3Mw. The gear units come from a range of equipment across most industries with the bulk of our contracts in the Wind sector. PGC is situated on a 45 acre site with lifting capacity of up to 90 tones.

Our industries include:

PGC also offer on site inspections using the latest imaging technology from Olympus. These inspections range from full end of warranty to one off inspections. We pride ourselves in being able to be on site within 24 hours in the UK and Ireland.

PGC have a machine shop, which has been set up primarily for the remanufacture of components in gear units. A Faro Arm (Quantum) is used to measure all journals before and after repair.

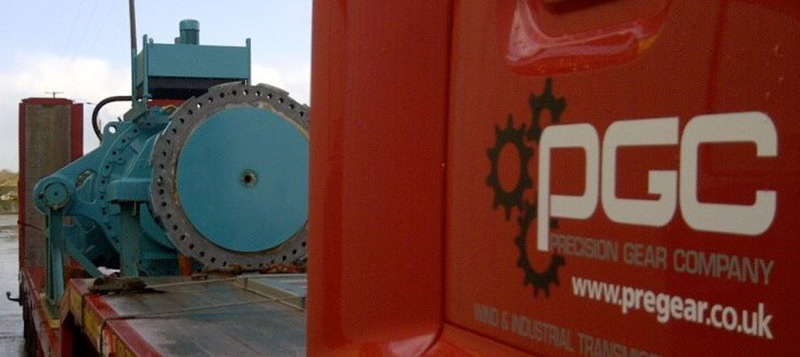

We also have our own transport division, which operates through out the UK and Ireland giving PGC full flexibility when it comes to collection and delivery of gearboxes. Sub-contract haulage is fine in many industries but there are very few haulage companies that understand the wind industry and the challenges it brings. For this reason PGC tends to use its own transport where possible.

In-House Design

- PGC utilise the very latest CAD software (Autodesk Inventor)

- Use of a Faro arm for measurement of bearing journals enables PGC to ensure precision reporting

What we do:

- PGC understands the need for fast efficient turn around of wind turbine and industrial gearboxes.

- PGC have the capacity to refurbish large wind turbine gearboxes up to 3.5mw or industrial units up to 32 tonnes. The units can be collected throughout Europe.

- PGC can provide full gearbox inspection using their trained staff in conjunction with the latest imaging and noise technology.

- Gearbox removal (through partners)

- Gearbox transport

- Gearbox Inspection (including onsite)

- Gearbox dismantle and reporting

- Oil sampling and reporting

- Gearbox upgrades (OEM instruction)

- Gearbox rebuild and final report

- Gearbox installation (through partners)

PGC would like to have a moment of your time to give you an update of our company's current capabilities and ongoing projects. PGC are active in the refurbishment of gear units ranging from 20Kw up to 3Mw. The gear units come from a range of equipment across most industries with the bulk of our contracts in the Wind sector. PGC is situated on a 45 acre site with lifting capacity of up to 90 tones.

Our industries include:

- Wind

- Rail

- Marine

- Mining

PGC also offer on site inspections using the latest imaging technology from Olympus. These inspections range from full end of warranty to one off inspections. We pride ourselves in being able to be on site within 24 hours in the UK and Ireland.

PGC have a machine shop, which has been set up primarily for the remanufacture of components in gear units. A Faro Arm (Quantum) is used to measure all journals before and after repair.

We also have our own transport division, which operates through out the UK and Ireland giving PGC full flexibility when it comes to collection and delivery of gearboxes. Sub-contract haulage is fine in many industries but there are very few haulage companies that understand the wind industry and the challenges it brings. For this reason PGC tends to use its own transport where possible.

In-House Design

- PGC utilise the very latest CAD software (Autodesk Inventor)

- Use of a Faro arm for measurement of bearing journals enables PGC to ensure precision reporting

What we do:

- Design Consultancy

- Gear and component Manufacture

- General Machining

- Full on site inspection @ Bora scope

- Transmission Repair/Refurbishment

- Wind Turbine Gearbox Repair/Refurbishment

- Transmission Assembly

- PGC have introduced our own unique gearbox reporting system

- Each unit is delivered with a thorough documentation of the work carried out

- Every gearbox is subject to a final analysis report including extensive photographs

- All gearboxes are given a unique ID number for simple reference

- PGC follow an extensive strip and build procedure

- All actions are documented and findings reported during the procedure

- Each gearbox leaves PGC with a unique documentation pack

UK

UK Ireland

Ireland Scotland

Scotland London

London