Address

Unit 2 Acorn Buisness Park

Airedale Buisness Centre

Airedale Buisness Centre

Skipton

North Yorkshire

Keighsley Road

BD23 2UE

About Sigmat

From its inception in 2001, Sigmat has uniquely specialised in the design, manufacture and build of load bearing light gauge steel framed (LGSF) structures to meet the burgeoning demand for offsite construction solutions. Our innovative approach has ensured that we are the largest constructor in this sector.

As a team, we have decades of relevant experience in steel frame and structural steel projects, as well as a detailed working knowledge of the industry-leading software and technologies used in the design and manufacturing process.

Experts in offsite DfMA:

We provide a seamless process from plans and assembly drawings to site-ready panels. Our offsite capacity enables multiple components and frames to be manufactured and assembled simultaneously. This efficiency is aided by our in-house logistics services which plan ahead for delivery and on-site installation.

Design for Manufacture and Assembly (DfMA)

Our mindset is one of DfMA. This fosters efficiency, certainty and cost effectiveness which helps us to achieve the earliest possible return upon investment for our customers. Our carefully managed processes deliver a higher quality cost effective solution and in less time.

By taking responsibility for the entire offsite project management we effectively communicate between each stage of the offsite process, eliminating waste and delays both off and on-site, ensuring that follow on trades are seamlessly added to the build programme after our work is done.

Our Engineered System

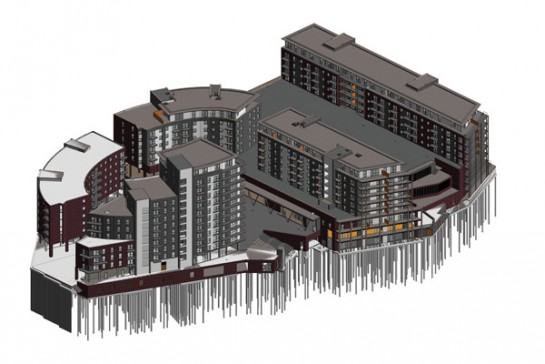

Light Gauge Steel Framing solutions up to 15 storeys. If you’re going to make something better then you need to consistently question and refine a product or process in order to optimise its effectiveness and efficiency.

Sigmat take this approach with offsite load bearing light gauge steel framing.

Rather than buy in random steel sections and modify them in order for them to work together we have designed, refined and manufactured a system solution to ensure it is the best available. Every single section, every single profile and every single accessory and ancillary fitting has been intelligently engineered to complement the rest. Nothing is unnecessarily added and nothing is wasted. Robust efficiency is the key.

4 Step Solution

1. Design

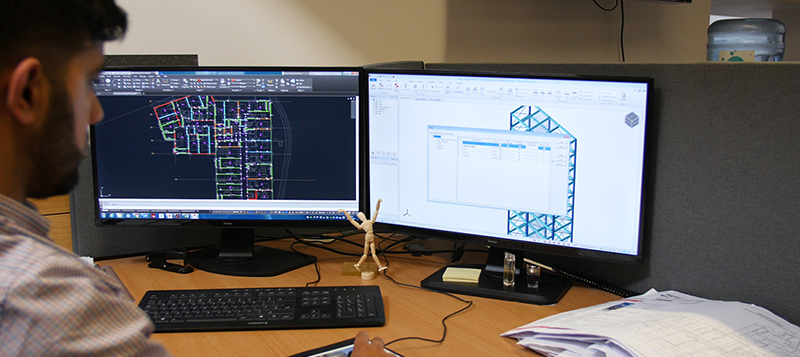

Our in-house building designers and Structural Engineers utilise Tekla BIM software to design the appropriate and most efficient building super structures that are EC3 and NHBC compliant. Each solution is rendered via Tekla into a 3D, BIM ready model.

2. Manufacture

Once the design is approved, information from Tekla is automatically transferred directly to our cold roll forming mills, ensuring absolute accuracy from design to manufacturing of every section and profile. Each component is barcoded to track each part from manufacturing to delivery on site.

3. Assemble

Our controlled offsite assembly facility enables us to pre-assemble our load bearing storey height panels prior to delivery.

4. Install

Less time spent on site is less money spent on the build. Sigmat light gauge steel frame rapidly constructs the building superstructure and importantly enables follow on trades to begin their element of works earlier.

Technical Leadership

Manufacturing capability and product ingenuity. Our roll forming mills manufacture our patented Light Gauge Steel Framing System. The mill is fitted with fully automated data control systems to receive the numerical manufacturing data direct from our 3D CAD modelling software in pre-determined phases. A unique reference mark is clearly printed on each piece we produce.

It allows the manufacture of our steel profiles to significantly better tolerances than were previously available in the industry. The tight corner radii ensure we achieve full contact end bearing for our studs, which are manufactured to exact lengths and piercing tolerances.

Panel Assembly

Following manufacture of the cold rolled profiles, individual panel bundles and pre-fabricated hot rolled elements are transferred to the assembly bays. These are then placed on rolling conveyor assembly lines in our factory to form storey-height panels up to 7.5m in length, eliminating the need to handle the panels until they are complete. External wall panels will also include any necessary boarding/insulation as specified.

All panels are quality control checked then stacked in to panel packs ready for loading onto our transport for delivery to site.

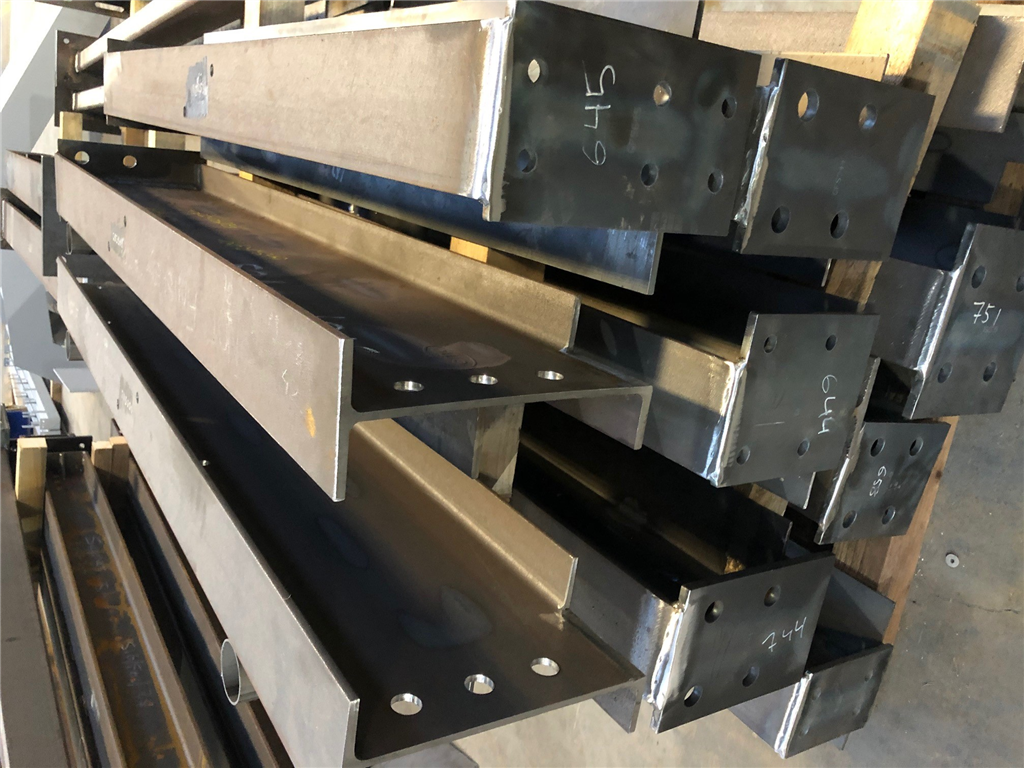

Fabrication Services

We fabricate a full range of additional structural steel elements to offer our clients a complete structural solution from one reliable source.

We also manufacture a variety of hot rolled steel elements, including steel stairs and balcony steel work. These are shot blasted to Sa2.5 standard and coated with primer paint or a hot dip galvanised finish where required.

To see our full brochure, please click here.

Video Gallery

Video 01

Video 02

Video 03

As a team, we have decades of relevant experience in steel frame and structural steel projects, as well as a detailed working knowledge of the industry-leading software and technologies used in the design and manufacturing process.

Experts in offsite DfMA:

- Innovation in a rapidly growing market

- Supplying more load bearing LGSF than other LGS contractor/installer

- Register for the Sigmat LGSF CPD

We provide a seamless process from plans and assembly drawings to site-ready panels. Our offsite capacity enables multiple components and frames to be manufactured and assembled simultaneously. This efficiency is aided by our in-house logistics services which plan ahead for delivery and on-site installation.

Design for Manufacture and Assembly (DfMA)

Our mindset is one of DfMA. This fosters efficiency, certainty and cost effectiveness which helps us to achieve the earliest possible return upon investment for our customers. Our carefully managed processes deliver a higher quality cost effective solution and in less time.

By taking responsibility for the entire offsite project management we effectively communicate between each stage of the offsite process, eliminating waste and delays both off and on-site, ensuring that follow on trades are seamlessly added to the build programme after our work is done.

Our Engineered System

Light Gauge Steel Framing solutions up to 15 storeys. If you’re going to make something better then you need to consistently question and refine a product or process in order to optimise its effectiveness and efficiency.

Sigmat take this approach with offsite load bearing light gauge steel framing.

Rather than buy in random steel sections and modify them in order for them to work together we have designed, refined and manufactured a system solution to ensure it is the best available. Every single section, every single profile and every single accessory and ancillary fitting has been intelligently engineered to complement the rest. Nothing is unnecessarily added and nothing is wasted. Robust efficiency is the key.

4 Step Solution

1. Design

Our in-house building designers and Structural Engineers utilise Tekla BIM software to design the appropriate and most efficient building super structures that are EC3 and NHBC compliant. Each solution is rendered via Tekla into a 3D, BIM ready model.

2. Manufacture

Once the design is approved, information from Tekla is automatically transferred directly to our cold roll forming mills, ensuring absolute accuracy from design to manufacturing of every section and profile. Each component is barcoded to track each part from manufacturing to delivery on site.

3. Assemble

Our controlled offsite assembly facility enables us to pre-assemble our load bearing storey height panels prior to delivery.

4. Install

Less time spent on site is less money spent on the build. Sigmat light gauge steel frame rapidly constructs the building superstructure and importantly enables follow on trades to begin their element of works earlier.

Technical Leadership

Manufacturing capability and product ingenuity. Our roll forming mills manufacture our patented Light Gauge Steel Framing System. The mill is fitted with fully automated data control systems to receive the numerical manufacturing data direct from our 3D CAD modelling software in pre-determined phases. A unique reference mark is clearly printed on each piece we produce.

It allows the manufacture of our steel profiles to significantly better tolerances than were previously available in the industry. The tight corner radii ensure we achieve full contact end bearing for our studs, which are manufactured to exact lengths and piercing tolerances.

Panel Assembly

Following manufacture of the cold rolled profiles, individual panel bundles and pre-fabricated hot rolled elements are transferred to the assembly bays. These are then placed on rolling conveyor assembly lines in our factory to form storey-height panels up to 7.5m in length, eliminating the need to handle the panels until they are complete. External wall panels will also include any necessary boarding/insulation as specified.

All panels are quality control checked then stacked in to panel packs ready for loading onto our transport for delivery to site.

Fabrication Services

We fabricate a full range of additional structural steel elements to offer our clients a complete structural solution from one reliable source.

We also manufacture a variety of hot rolled steel elements, including steel stairs and balcony steel work. These are shot blasted to Sa2.5 standard and coated with primer paint or a hot dip galvanised finish where required.

To see our full brochure, please click here.

Video Gallery

Video 01

Video 02

Video 03

Gallery

News

Sigmat awarded light gauge steel frame contract by GMI Construction Group for Hampton by Hilton Hotel in York

Following the announcement by GMI Construction Group at the end of 2019, Sigmat announce the award of the light gauge steel frame contract on the Hampton by Hilton Hotel located at the Piccadilly site in the heart of York. Sigmat team are due to be onsite from the end of February 2020, with the overall project for GMI completing in the first quarter of 2021. The 143 bedroom hotel is the third project that Sigmat have been awarded by GMI, and is the first Hampton by Hilton project.

Piccadilly Site is situated in the Castle Gateway district of the city, and, together with neighbouring streets, has been identified by the City Council as an area for major regeneration and redevelopment.

In addition to its 143 guest bedrooms, the hotel site will also include a 4-storey luxury private apartment block which will also be constructed in light gauge steel.

Read more about GMI Construction and the project here.

Following the announcement by GMI Construction Group at the end of 2019, Sigmat announce the award of the light gauge steel frame contract on the Hampton by Hilton Hotel located at the Piccadilly site in the heart of York. Sigmat team are due to be onsite from the end of February 2020, with the overall project for GMI completing in the first quarter of 2021. The 143 bedroom hotel is the third project that Sigmat have been awarded by GMI, and is the first Hampton by Hilton project.

Piccadilly Site is situated in the Castle Gateway district of the city, and, together with neighbouring streets, has been identified by the City Council as an area for major regeneration and redevelopment.

In addition to its 143 guest bedrooms, the hotel site will also include a 4-storey luxury private apartment block which will also be constructed in light gauge steel.

Read more about GMI Construction and the project here.

1st November sees Sigmat expand their capabilities with the opening of a new 50,000 sqft Contract Support Centre (CSC), located 500m from the already existing 100,000 sqft manufacturing facility in Leeds.

The opening of the CSC is Sigmat's 7th location, strengthening their nationwide presence and proficiency. The new CSC is dedicated to support on-site teams, a core part of Sigmat's customer-focused strategy.

Sigmat's locations:

•Sigmat HQ, Skipton

•Sigmat Manufacturing Facility, Leeds

•Sigmat Contract Support Centre, Leeds

•R&D Centre, Evesham

•Teesside Regional Office

•Glasgow Regional Office

•Elland Regional Office

The opening of the CSC is Sigmat's 7th location, strengthening their nationwide presence and proficiency. The new CSC is dedicated to support on-site teams, a core part of Sigmat's customer-focused strategy.

Sigmat's locations:

•Sigmat HQ, Skipton

•Sigmat Manufacturing Facility, Leeds

•Sigmat Contract Support Centre, Leeds

•R&D Centre, Evesham

•Teesside Regional Office

•Glasgow Regional Office

•Elland Regional Office

UK

UK Ireland

Ireland Scotland

Scotland London

London