About WeBuildEco

We create energy-efficient building kits from any design. Our process is fast and precise. Our kits are easy to assemble. Our buildings are natural, healthy and sustainable. Join us and explore a construction process that makes sense logically, economically and ecologically.

You send us your simplest drawings and we convert them into a We Build Eco house which is delivered as a kit. Our software and expertise translate 2D plans into a 3D design which is then converted into an exact guide suitable for our cutting equipment.

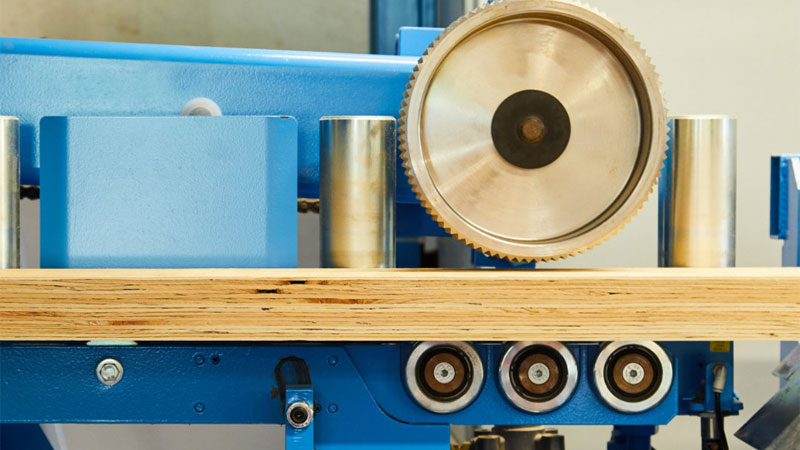

Working with an automated cutting list, the elements are cut, labelled and marked. Our 5-axis Hundegger saw seemlessly interfaces with 3D software and is unerringly accurate to 1.5mm. We conduct regular spot checks to make sure – precision means a massive reduction in installer error.

Our building shells are delivered as a kit, with pre-packed sections in assembly order. The elements are clearly labelled and flat-packed for low-cost transportation. Natural insulation, membranes, tapes, connecting plates, gussets, fixings and racking boards are all included.

The building process is seemless, and the skillset required in minimal. It saves time, labour costs and the cost of waste removal. You won’t even need a crane. If weather is an issue, cassettes can be pre-built in a local warehouse and assembled on site.

We use all-natural materials because it just makes sense. Natural insulation outperforms synthetic and the use of plastics or oil-based products is not sustainable. Our buildings store carbon and offer passive levels of airtightness and thermal performance. No heating system required. They are vapour blocking and hygroscopic so produce a healthy living environment with no toxins.

Let our factory become your factory. If you are a developer, builder, or timber-framer selling beyond your capacity use We Build Eco to increase your output. No need for costly capital-intensive equipment or facilities.

Bring your clients to visit our factory and think of us as skilled employees who are not on your payroll. Our factory is located on a picturesque farm in the South Downs National Park and makes use of extensive PV arrays to reduce emissions.

OUR EXPERTISE.

The dimensions on your 2D plans are entered into our 3D Cadworks programme using our library of panels for the walls and roof. These are based on Steico I Joists ranging from 160mm to 400mm wide. Working to the target section U values each section is then designed with an internal vapour/airtight racking board and an external rigid wood fibre board or rigid wood fibre board with a wind/weathertight membrane.

ENGINEERING.

Our state-of-the-art Hundegger Turbo Drive saw has a flexible 5-axis blade unit which pivots 360˚ with a 90˚ tilt function this allows cuts at any angle and inclination including both compound and bevel. This level of flexibility and precision ensures we consistently meet our own exacting tolerances for the cut elements and ensures that even the most compllcated cuts are completed to the highest levels of accuracy, way beyond what is typically possible on-site or by hand cutting.

ASSEMBLY.

Cut LVL and I Joists are packaged on bearers that are up to 1.2m wide and in units less than 2 tons, we use steel banding so that all our packaging is recyclable. Pack numbers are individually marked in sequence and shown on the supplied assembly instructions, this helps on-site storage and handling eliminating wasted time and facilitating speedy erection. Using a flatpack format for packing and handling reduces transport costs and is easier to store dry as it requires less area.

UK

UK Ireland

Ireland Scotland

Scotland London

London