Address

Unit B, Harwood Rd

Littlehampton

West Sussex

South East England

BN17 7AU

About GP Products Waterjet Cutting Services

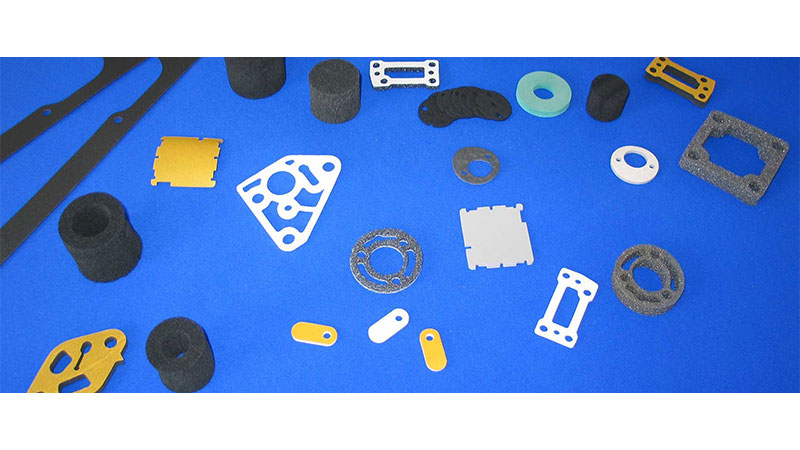

GP Products UK are manufacturers of foam inserts, cut sponge products, paper gaskets, ptfe bushes, rubber strips, cork washers, silicone sealing products, plastic cut parts, graphite seals, presentation case inserts & aluminium sealing components. We have literally thousands of material types and grades available from stock and our specialisation is in the manufacture of self adhesive components.

If you are manufacturing or producing prototype products utilising cut components, we can provide you with your requirements efficiently & economically.

Our modern techniques, water jet cutting and die cut facilities together with deliveries to suit your schedules result in premium service levels as standard and economical prices.

With over 30 years experience in technical sealing expertise we can help you with prototyping, design, manufacture or subcontract assembly in any batch sizes. We have no minimum quantity and we can manufacture from drawings, CAD files or in some cases from your sample.

We are proud of our association with many household names and we supply technical sealing solutions to industrial clients in Aerospace, Automotive, Civil Engineering, Electrical, Food, Healthcare, Marine, Oil/Gas, Pharmaceutical, Petrochemicals, Water and Waste industries. We are certified to BSI ISO 9001: 2015.

Water Jet Cutting

This is the most modern process & has involved us in major investment in state of the art machines. It utilises water & abrasives which are mixed to create a fine beam of fluid that will cut through almost any material. The water is compressed to 4000 bar, (60,000 psi) and then forced through a directional nozzle which is controlled by a CAD/CAM system. This allows complex nesting on our cutting path saving valuable material.

Abrasives can be added to ensure that the cut is swift and smooth, with minimal edge burring and no material distortion when cutting hard materials. We can use this process to cut any material from paper, rubber, foam through to stainless steel, aluminium, marble & ceramics.

The key benefits of this process include no tooling, no material distortion or discolouration, no product burring, accuracy to within 0.1mm and suitability to both small & long runs.

We can use water jet cutting with polished surfaces and for materials up to 100mm thick. Tight radii cuts can be achieved accurately & reliably and cost savings result through complex nesting of the same or different components.

UK

UK Ireland

Ireland Scotland

Scotland London

London