Telephone

Click to view

Website

Contact

Enquiries

Address

2A Old Racecourse Road

Millmead Buildings

Millmead Buildings

Liverpool

L31 8BU

About MS Laser Services Ltd

MS Laser Services Ltd – Precision Metal Fabrication & Cutting Solutions

Specialists in One-Offs & Production Runs, Design & Prototyping, Samples

At MS Laser Services Ltd, we bring over 40 years of metalworking expertise to deliver high-quality laser cutting and metal fabrication solutions with fast turnaround times and competitive pricing. Our in-house stock of stainless steel, aluminium, brass, copper, and zinc allows us to reduce lead times and provide cost-effective solutions for both one-off projects and large production runs.

Comprehensive Metal Fabrication Services

We are more than just laser cutting—our full range of services makes us a one-stop shop for bespoke metal fabrication, including:

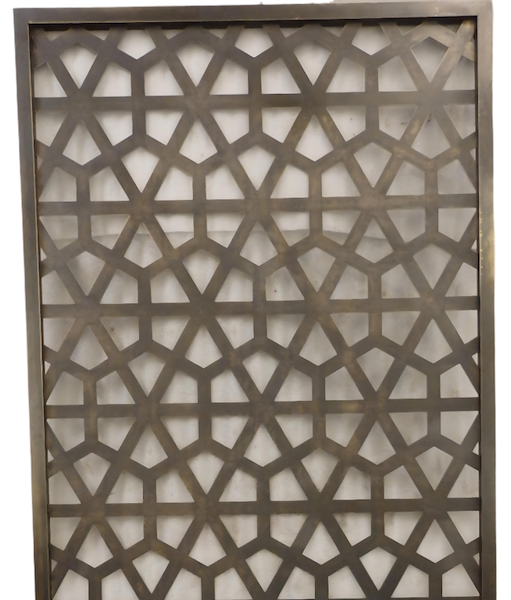

Fiber Laser Cutting – Advanced LX3015 3kW fiber laser for precise, clean cuts across a variety of metals. Our 3m x 1.5m cutting bed handles both intricate designs and large-scale components.

Guillotine Cutting – Cost-effective straight cutting using NC-controlled guillotines (3.0m, 2.5m, 2.0m) for sheets up to 6mm thick.

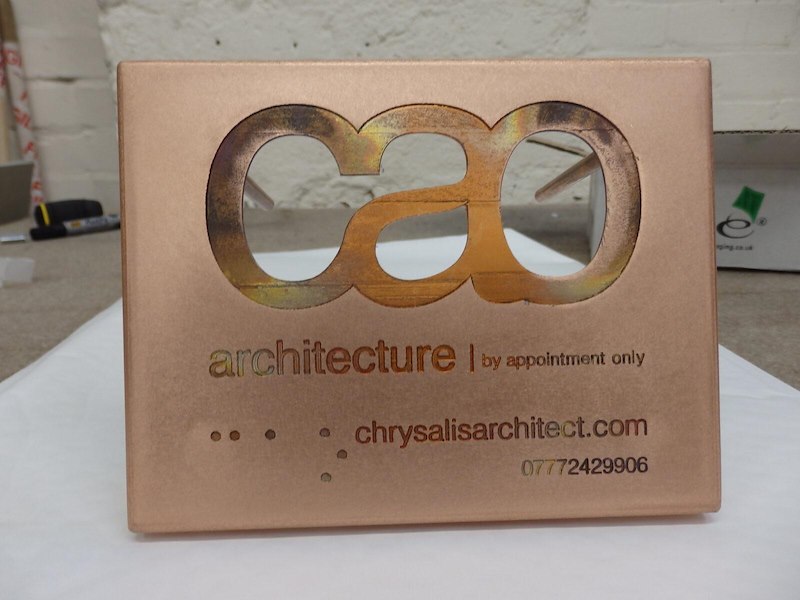

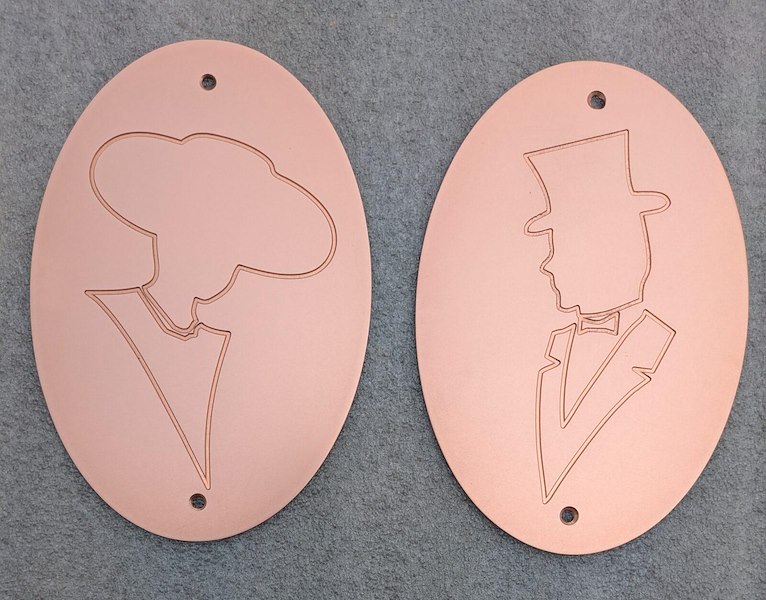

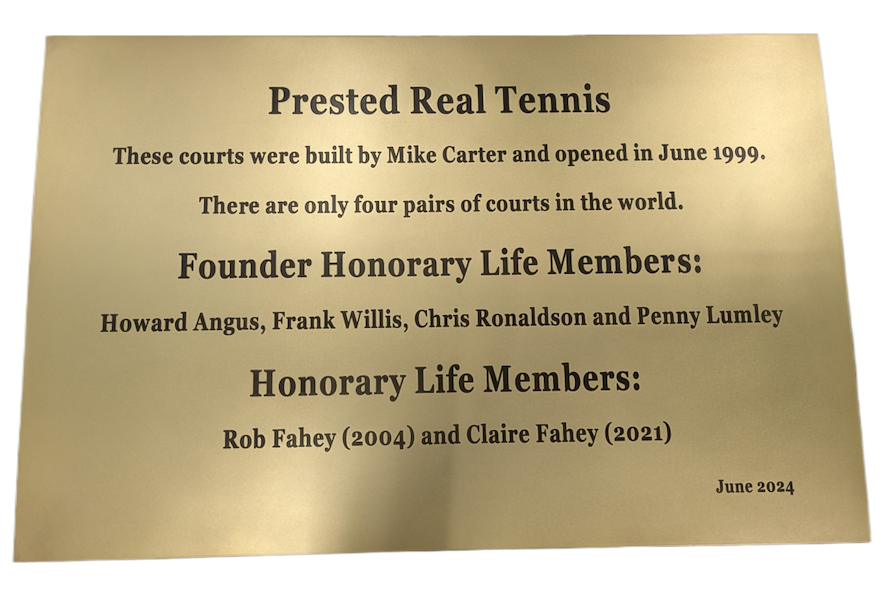

CNC Machining & Engraving – Our 3m x 1.5m CNC router engraves and machines brass, copper, aluminium, zinc, pewter, timber, dibond, and plastics—ideal for engraved brass signage and lettering up to 2.4m x 1.2m.

Press Braking & Metal Bending – Amada press brakes with up to 3m x 100-tonne capacity for precision bending.

Metal Finishing & Patina Work – Specialists in aged, industrial, antique, and rusted patina finishes for brass, copper, zinc, and Corten steel, with in-house clear lacquer coating for durability.

Spin Forming – Metal spinning lathes for TableTops (up to 1000mm), Sinks, Bowls, and other curved components in copper, brass, and zinc.

Welding – Expert MIG & TIG welding, specializing in copper and brass, as well as aluminium and stainless steel fabrication.

CAD & Design Support – Our CAD team can assist with DWG, DXF, and IGES formats, helping you optimize sheet usage and minimize waste.

Specialists in One-Offs & Production Runs, Design & Prototyping, Samples

At MS Laser Services Ltd, we bring over 40 years of metalworking expertise to deliver high-quality laser cutting and metal fabrication solutions with fast turnaround times and competitive pricing. Our in-house stock of stainless steel, aluminium, brass, copper, and zinc allows us to reduce lead times and provide cost-effective solutions for both one-off projects and large production runs.

Comprehensive Metal Fabrication Services

We are more than just laser cutting—our full range of services makes us a one-stop shop for bespoke metal fabrication, including:

Fiber Laser Cutting – Advanced LX3015 3kW fiber laser for precise, clean cuts across a variety of metals. Our 3m x 1.5m cutting bed handles both intricate designs and large-scale components.

Guillotine Cutting – Cost-effective straight cutting using NC-controlled guillotines (3.0m, 2.5m, 2.0m) for sheets up to 6mm thick.

CNC Machining & Engraving – Our 3m x 1.5m CNC router engraves and machines brass, copper, aluminium, zinc, pewter, timber, dibond, and plastics—ideal for engraved brass signage and lettering up to 2.4m x 1.2m.

Press Braking & Metal Bending – Amada press brakes with up to 3m x 100-tonne capacity for precision bending.

Metal Finishing & Patina Work – Specialists in aged, industrial, antique, and rusted patina finishes for brass, copper, zinc, and Corten steel, with in-house clear lacquer coating for durability.

Spin Forming – Metal spinning lathes for TableTops (up to 1000mm), Sinks, Bowls, and other curved components in copper, brass, and zinc.

Welding – Expert MIG & TIG welding, specializing in copper and brass, as well as aluminium and stainless steel fabrication.

CAD & Design Support – Our CAD team can assist with DWG, DXF, and IGES formats, helping you optimize sheet usage and minimize waste.

Gallery

News

What is Laser Cutting? A Beginner’s Guide to Precision Cutting

Introduction

Laser cutting has revolutionized the metal fabrication industry, offering precision, efficiency, and versatility that traditional cutting methods struggle to match. Whether you’re in manufacturing, architecture, or metalwork design, understanding how laser cutting works can help you make informed decisions for your projects.

In this guide, we’ll explore what laser cutting is, how it works, its benefits, and how MS Laser Services Ltd can help you achieve flawless metal cuts.

What is Laser Cutting?

Laser cutting is a technology that uses a high-powered laser beam to cut through materials with extreme precision. The laser melts, burns, or vaporizes the metal, leaving behind a smooth, clean edge with minimal waste.

At MS Laser Services Ltd, we use a 3kW fiber laser cutting machine capable of cutting stainless steel, aluminium, brass, copper, and zinc with high accuracy.

How Does Laser Cutting Work?

1 Generating the Laser Beam – A high-energy laser beam is created and directed through optics to focus the energy on a small point.

2 Material Interaction – The intense laser beam melts or burns through the metal, cutting along the programmed path.

3 Precision Control – The machine’s CNC system ensures exact dimensions, making laser cutting ideal for intricate designs and complex shapes.

Benefits of Laser Cutting

High Precision & Accuracy – Ideal for detailed and complex designs.

Fast & Efficient – Cuts quickly with minimal material waste.

Versatile Material Compatibility – Works on stainless steel, brass, copper, aluminium, and more.? Minimal Post-Processing – Leaves

smooth edges, reducing the need for additional finishing.

Applications of Laser Cutting

Industrial Manufacturing – Custom-cut parts for machinery and components.

Architectural & Decorative Panels – Precision-cut metal screens and signage.

Bespoke Metal Fabrication – Custom shapes for trade and DIY projects.

Prototyping & Small Batch Production – Cost-effective for testing designs before mass production.

Why Choose MS Laser Services Ltd?

At MS Laser Services, we provide precision sheet metal cutting with fast turnaround times. Whether you need one-off prototypes or

large-scale production runs, our team ensures exceptional quality and accuracy.

Materials We Cut: Stainless steel, aluminium, brass, copper, zinc.

Additional Services: Press braking (up to 3m), TIG/MIG welding, custom fabrication.

Get a Quote Today: Contact us for a competitive quote on your laser cutting project.

Final Thoughts

Laser cutting is an essential service for businesses and individuals who need precision metalwork. Whether you’re working on

architectural designs, industrial components, or bespoke fabrication, laser cutting delivers high-quality results with minimal waste.

For expert laser cutting services, reach out to MS Laser Services Ltd today!

Contact us at: contact@mslaserservices.co.uk

Call us at: 0151 458 9030

Visit our website:

https://mslaserservices.co.uk/

Introduction

Laser cutting has revolutionized the metal fabrication industry, offering precision, efficiency, and versatility that traditional cutting methods struggle to match. Whether you’re in manufacturing, architecture, or metalwork design, understanding how laser cutting works can help you make informed decisions for your projects.

In this guide, we’ll explore what laser cutting is, how it works, its benefits, and how MS Laser Services Ltd can help you achieve flawless metal cuts.

What is Laser Cutting?

Laser cutting is a technology that uses a high-powered laser beam to cut through materials with extreme precision. The laser melts, burns, or vaporizes the metal, leaving behind a smooth, clean edge with minimal waste.

At MS Laser Services Ltd, we use a 3kW fiber laser cutting machine capable of cutting stainless steel, aluminium, brass, copper, and zinc with high accuracy.

How Does Laser Cutting Work?

1 Generating the Laser Beam – A high-energy laser beam is created and directed through optics to focus the energy on a small point.

2 Material Interaction – The intense laser beam melts or burns through the metal, cutting along the programmed path.

3 Precision Control – The machine’s CNC system ensures exact dimensions, making laser cutting ideal for intricate designs and complex shapes.

Benefits of Laser Cutting

High Precision & Accuracy – Ideal for detailed and complex designs.

Fast & Efficient – Cuts quickly with minimal material waste.

Versatile Material Compatibility – Works on stainless steel, brass, copper, aluminium, and more.? Minimal Post-Processing – Leaves

smooth edges, reducing the need for additional finishing.

Applications of Laser Cutting

Industrial Manufacturing – Custom-cut parts for machinery and components.

Architectural & Decorative Panels – Precision-cut metal screens and signage.

Bespoke Metal Fabrication – Custom shapes for trade and DIY projects.

Prototyping & Small Batch Production – Cost-effective for testing designs before mass production.

Why Choose MS Laser Services Ltd?

At MS Laser Services, we provide precision sheet metal cutting with fast turnaround times. Whether you need one-off prototypes or

large-scale production runs, our team ensures exceptional quality and accuracy.

Materials We Cut: Stainless steel, aluminium, brass, copper, zinc.

Additional Services: Press braking (up to 3m), TIG/MIG welding, custom fabrication.

Get a Quote Today: Contact us for a competitive quote on your laser cutting project.

Final Thoughts

Laser cutting is an essential service for businesses and individuals who need precision metalwork. Whether you’re working on

architectural designs, industrial components, or bespoke fabrication, laser cutting delivers high-quality results with minimal waste.

For expert laser cutting services, reach out to MS Laser Services Ltd today!

Contact us at: contact@mslaserservices.co.uk

Call us at: 0151 458 9030

Visit our website:

https://mslaserservices.co.uk/

UK

UK Ireland

Ireland Scotland

Scotland London

London