Construction News

01/02/2010

Thames Water Chlorination

Under the Water Supply (water fittings) Regulations 1999 (SI 1999, 1148), you will be required to disinfect your underground pipe work prior to connection.

The disinfection must be carried out to 'BS6700'. This is to ensure there is no detriment to public health.

For further details and clarification, please refer to section G13.1 of the Guidance Notes to S1 1999, 1148 and clause 3.1.10 of BS6700.

New supplies should be swabbed, flushed, filled with chlorinated water not less than 50mg/l and allowed to stand for 1 hour, following which the chlorinated water should be flushed out, the pipe refilled, and a sample taken. The pipework must be disinfected with a 'hypochlorite solution'.

The following must be submitted to our office prior to the connection being made:

The certificate must clearly state that the disinfection has been carried out in accordance with BS6700. The 'method statement' must indicate the details of the disinfection carried out, the diameter and length of pipe disinfected, the source of the water used, the sample location point, and a diagram. The 'sample results' must include E-coli, total coliforms, turbidity, and plate counts taken at both 22°C and 37°C. The post flush chlorine level must also be confirmed by laboratory analysis. The sample results must be from a 'UKAS' accredited laboratory. It is the customer's responsibility to ensure that the designated disinfection company is aware of our requirements. If this procedure is not met we have a right to refuse the final connection, and the pipework must be re-disinfected to meet our requirements.

Please note that we cannot begin the connection process until we have received these documents complete with all information.

The disinfection certificate, the bacteriological sample results, and the method statement should be sent to 112 Broad Street Coventry CV6 5AZ or faxed to 0207 713 3888.

The disinfection must be carried out to 'BS6700'. This is to ensure there is no detriment to public health.

For further details and clarification, please refer to section G13.1 of the Guidance Notes to S1 1999, 1148 and clause 3.1.10 of BS6700.

New supplies should be swabbed, flushed, filled with chlorinated water not less than 50mg/l and allowed to stand for 1 hour, following which the chlorinated water should be flushed out, the pipe refilled, and a sample taken. The pipework must be disinfected with a 'hypochlorite solution'.

The following must be submitted to our office prior to the connection being made:

- A disinfection certificate

- A method statement of the disinfection process carried out

- The sample results

The certificate must clearly state that the disinfection has been carried out in accordance with BS6700. The 'method statement' must indicate the details of the disinfection carried out, the diameter and length of pipe disinfected, the source of the water used, the sample location point, and a diagram. The 'sample results' must include E-coli, total coliforms, turbidity, and plate counts taken at both 22°C and 37°C. The post flush chlorine level must also be confirmed by laboratory analysis. The sample results must be from a 'UKAS' accredited laboratory. It is the customer's responsibility to ensure that the designated disinfection company is aware of our requirements. If this procedure is not met we have a right to refuse the final connection, and the pipework must be re-disinfected to meet our requirements.

Please note that we cannot begin the connection process until we have received these documents complete with all information.

The disinfection certificate, the bacteriological sample results, and the method statement should be sent to 112 Broad Street Coventry CV6 5AZ or faxed to 0207 713 3888.

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

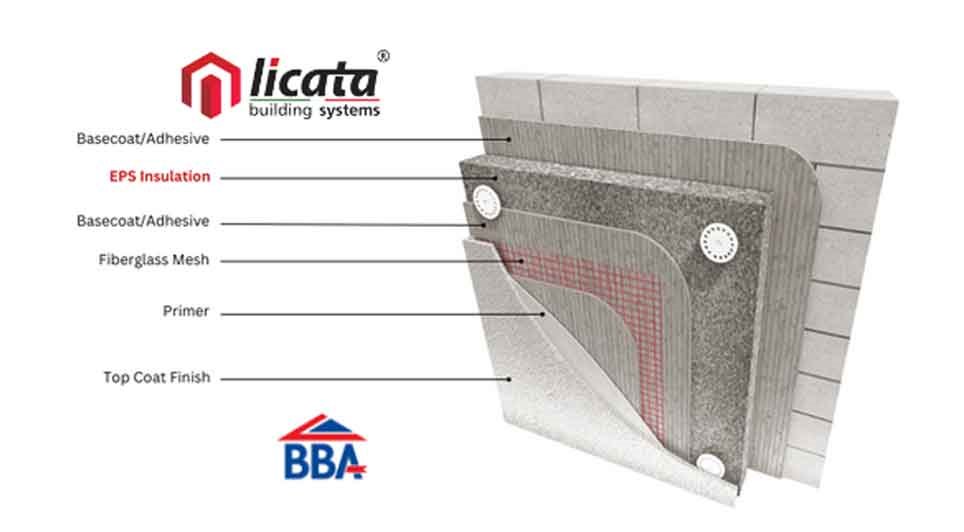

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London