Construction News

10/03/2010

Rofin PowerLine Eases Fine Cutting

An innovative high-tech device for beam quality and pulse to pulse stability has been developed.

Rofin designs and builds industrial lasers and systems for laser welding, marking, etching and engraving as well as for laser cutting of metals and non-metals and surface modification and ablation with the company's new PowerLine SL 8 IC made specifically for the fine cutting operations required on TFTs.

The beam source has been optimised to meet strict requirements on beam quality and pulse to pulse stability at high frequencies.

A temperature management system with independent thermal monitoring, stabilization of all relevant optical components and heat dissipation via a cooling plate ensures long-term stability and performance, which is necessary for reliable continuous operation.

A company spoesman said: "When we look around our home, or car for that matter, it seems that almost every electronic device has an LCD display of some description, with screen sizes ranging from miniature to over 50 inches in the case of LCD televisions.

"In the vast majority of cases, every pixel in the screen is active.

"The rows and columns of the pixel matrix are activated using transparent indium tin oxide (ITO) conductive paths. As part of the process in the production of TFT displays, a conductive connection must be established between the rows and columns of the matrix – an intentional short circuit, as it were. However, at a later stage in the production process, this step must be carefully undone.

"The power and precision of Rofin's new PowerLine SL 8 IC laser makes it the ideal tool for this intricate task," he enthused.

TFT panel edge can sometimes be over a metre long and the connection groups are distributed over the whole length.

Each group of conductive paths has to be cut accurately and absolutely reliably with a line width of just 35 μm +/- 5 μm.

In addition to the high accuracy required for this application, leading screen manufacturers demand processing speeds in excess of 400mm / second. These requirements for accuracy and speed combined with the physical size of the larger components poses some interesting production challenges.

He also said that Galvo deflection heads are often used to position a laser beam across the working area, however with a processing field of this size the resultant spot diameter would be too large, meaning the narrow line widths required could not be guaranteed across the whole field.

The solution therefore is to use fixed optics, with the laser and optics combination mounted to one motor driven axis and the panel moved in the other direction by a separate axis.

To maintain the high processing speeds demanded by manufacturers the laser needs to be both powerful and compact.

The PowerLine SL 8 IC reliably cuts ITO conductive paths with the specified line width of 35 µm, and the power available from this new laser means that it is capable of achieving much higher speeds than the 400 mm / second demanded by the leading screen manufacturers.

More details: www.rofin.co.uk

(BMcC/GK)

Rofin designs and builds industrial lasers and systems for laser welding, marking, etching and engraving as well as for laser cutting of metals and non-metals and surface modification and ablation with the company's new PowerLine SL 8 IC made specifically for the fine cutting operations required on TFTs.

The beam source has been optimised to meet strict requirements on beam quality and pulse to pulse stability at high frequencies.

A temperature management system with independent thermal monitoring, stabilization of all relevant optical components and heat dissipation via a cooling plate ensures long-term stability and performance, which is necessary for reliable continuous operation.

A company spoesman said: "When we look around our home, or car for that matter, it seems that almost every electronic device has an LCD display of some description, with screen sizes ranging from miniature to over 50 inches in the case of LCD televisions.

"In the vast majority of cases, every pixel in the screen is active.

"The rows and columns of the pixel matrix are activated using transparent indium tin oxide (ITO) conductive paths. As part of the process in the production of TFT displays, a conductive connection must be established between the rows and columns of the matrix – an intentional short circuit, as it were. However, at a later stage in the production process, this step must be carefully undone.

"The power and precision of Rofin's new PowerLine SL 8 IC laser makes it the ideal tool for this intricate task," he enthused.

TFT panel edge can sometimes be over a metre long and the connection groups are distributed over the whole length.

Each group of conductive paths has to be cut accurately and absolutely reliably with a line width of just 35 μm +/- 5 μm.

In addition to the high accuracy required for this application, leading screen manufacturers demand processing speeds in excess of 400mm / second. These requirements for accuracy and speed combined with the physical size of the larger components poses some interesting production challenges.

He also said that Galvo deflection heads are often used to position a laser beam across the working area, however with a processing field of this size the resultant spot diameter would be too large, meaning the narrow line widths required could not be guaranteed across the whole field.

The solution therefore is to use fixed optics, with the laser and optics combination mounted to one motor driven axis and the panel moved in the other direction by a separate axis.

To maintain the high processing speeds demanded by manufacturers the laser needs to be both powerful and compact.

The PowerLine SL 8 IC reliably cuts ITO conductive paths with the specified line width of 35 µm, and the power available from this new laser means that it is capable of achieving much higher speeds than the 400 mm / second demanded by the leading screen manufacturers.

More details: www.rofin.co.uk

(BMcC/GK)

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

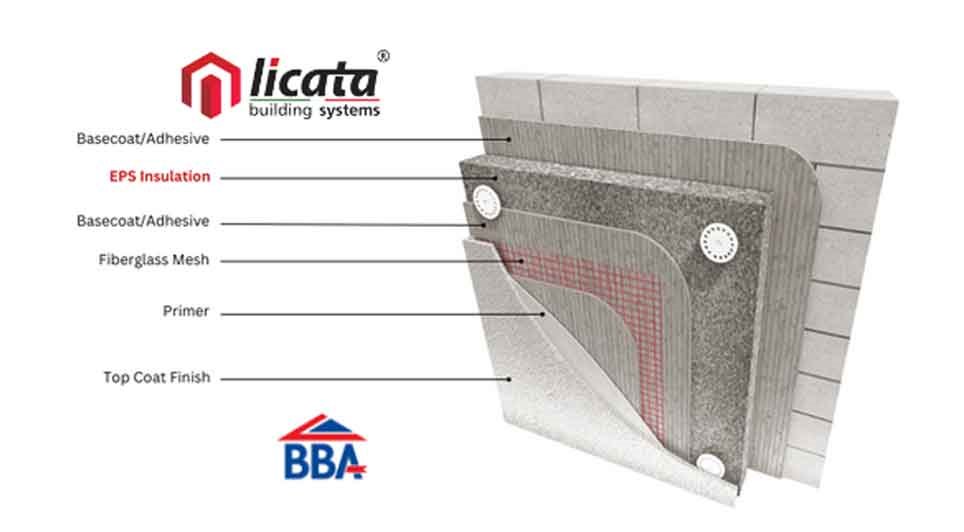

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London