Construction News

08/11/2010

New Production Line Reduces Cost On School Development Projects

The Autumn saw GRP Canopies launch their best ever deal on domestic carports and canopies as a direct result in improved production facilities and capacity.

Now with funding cuts everywhere and many public projects feeling the pinch of harsh economic times the company has expanded the cost savings to their dedicated school canopy division.

Mark McLean, who leads GRP Canopies Engineering and Design team, has now extended the production optimisation onto the manufacturer of larger structures allowing the overall production cost to be reduced resulting in cost savings across the board right down to what the customer is required to pay.

Mark explained: "Every business has to continually look to improve both their method of production from both the perspective of product improvements and cost savings in manufacture. GRP Canopies have now secured several overseas contracts, primarily in the West Indies, where we have established a reputation as the ONLY company capable of providing hurricane proof canopies. We have always prided ourselves on the quality of our products however one cannot ignore the realities of the economic climate we are currently in. This means that the cost of our products must be kept to a minimum to ensure we can supply to schools and nurseries in the UK on tight budgets with limited resources. It has been well publicised that the UK's manufacturing base has been in steady decline for many years and we are proud of GRP Canopies achievements in, not only continuing to buck the trend, but are also now moving to export and competing against the rest of the world on quality and price."

Large canopy structures can have a variety of uses in schools and nurseries. From providing additional area for outdoor teaching and covered play areas to offering weather protection to fixtures and equipment. GRP Canopies do not supply canopies for self fitting but employ their own dedicated, fully trained, installation teams who operate throughout the UK. The companies strict policy of quality control and quality of services means that on completion ever customer is requested to provide feedback on all aspects of the installation to allow continual monitoring and self improvement throughout the whole process from design, manufacture through to delivery and installation. ALL staff employed in the process are fully CRB checked with copies of all certificates held in the companies head office.

Company CEO Robin Marlin said:"It's all too easy to trim costs by corner cutting and reducing the quality of the products we supply. However our philosophy has always been to look at reducing costs by examining all aspects of the way we do business and seeking savings that do not impact in any way in the quality of our products or in the professional manner in which these are installed. We have seen several of our competitors seek to win business in this manner but such practices usually come back to haunt you and in several well-publicised cases that is exactly what has happened. Our membership of LABC, and associations with several large developers in England and Wales involved in school refurbishments projects, has seen the company forge a reputation for quality and professionalism that all our staff can be proud of."

GRP Canopies are also in the process of finalising their new product range of glass verandas scheduled to be available in the early part of 2011. The new patented designs represent a significant investment in development, staff training and manufacturing equipment. It just goes to show that even in the most difficult of times attention to detail and providing a quality product backed by a quality service can allow a company to flourish.

For further information contact: Gerry Shields, GRP Canopies Ltd, on Tel: 0800 783 3835 or Visit: www.123v.com

(CD/KMcA)

Now with funding cuts everywhere and many public projects feeling the pinch of harsh economic times the company has expanded the cost savings to their dedicated school canopy division.

Mark McLean, who leads GRP Canopies Engineering and Design team, has now extended the production optimisation onto the manufacturer of larger structures allowing the overall production cost to be reduced resulting in cost savings across the board right down to what the customer is required to pay.

Mark explained: "Every business has to continually look to improve both their method of production from both the perspective of product improvements and cost savings in manufacture. GRP Canopies have now secured several overseas contracts, primarily in the West Indies, where we have established a reputation as the ONLY company capable of providing hurricane proof canopies. We have always prided ourselves on the quality of our products however one cannot ignore the realities of the economic climate we are currently in. This means that the cost of our products must be kept to a minimum to ensure we can supply to schools and nurseries in the UK on tight budgets with limited resources. It has been well publicised that the UK's manufacturing base has been in steady decline for many years and we are proud of GRP Canopies achievements in, not only continuing to buck the trend, but are also now moving to export and competing against the rest of the world on quality and price."

Large canopy structures can have a variety of uses in schools and nurseries. From providing additional area for outdoor teaching and covered play areas to offering weather protection to fixtures and equipment. GRP Canopies do not supply canopies for self fitting but employ their own dedicated, fully trained, installation teams who operate throughout the UK. The companies strict policy of quality control and quality of services means that on completion ever customer is requested to provide feedback on all aspects of the installation to allow continual monitoring and self improvement throughout the whole process from design, manufacture through to delivery and installation. ALL staff employed in the process are fully CRB checked with copies of all certificates held in the companies head office.

Company CEO Robin Marlin said:"It's all too easy to trim costs by corner cutting and reducing the quality of the products we supply. However our philosophy has always been to look at reducing costs by examining all aspects of the way we do business and seeking savings that do not impact in any way in the quality of our products or in the professional manner in which these are installed. We have seen several of our competitors seek to win business in this manner but such practices usually come back to haunt you and in several well-publicised cases that is exactly what has happened. Our membership of LABC, and associations with several large developers in England and Wales involved in school refurbishments projects, has seen the company forge a reputation for quality and professionalism that all our staff can be proud of."

GRP Canopies are also in the process of finalising their new product range of glass verandas scheduled to be available in the early part of 2011. The new patented designs represent a significant investment in development, staff training and manufacturing equipment. It just goes to show that even in the most difficult of times attention to detail and providing a quality product backed by a quality service can allow a company to flourish.

For further information contact: Gerry Shields, GRP Canopies Ltd, on Tel: 0800 783 3835 or Visit: www.123v.com

(CD/KMcA)

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

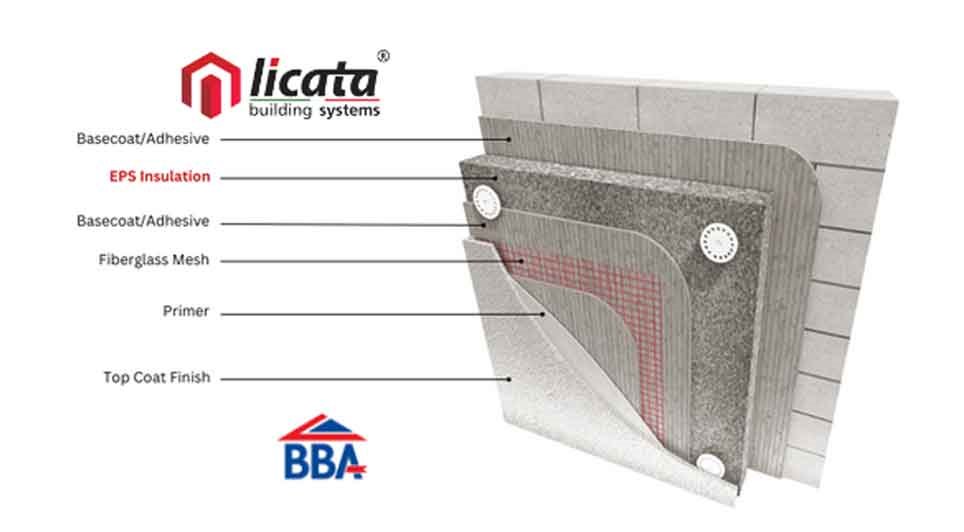

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London