Construction News

13/10/2011

Waterproofing An Existing Basement – A Quick Guide

newton-membranes.co.uk/news/basement-waterproofing/waterproofing-an-existing-basement/

When you are looking at waterproofing an existing basement you have a large variety of products available at your disposal. The real key is choosing the right product, the right preparation technique and for the right price to achieve the degree of waterproofing you need for your intended use of the basement.

So let's go through a quick guide for you to get the ball rolling. When waterproofing an existing basement, you are either going to:

1. Hold water back by applying a system to the basement such as cementitious slurry or similar or

2. Install a cavity drain system which will divert the water and get rid of it prior to damaging internal finishes.

Firstly what needs to be considered is – what are you using the space for? If it is a bike shed then you are not going to insulate it or go to a massive effort to rake out the mortar joints etc. The big cost will be the prep here and of course it will take a while for the render approach to dry. If you are happy with the risk of water ingress coming out on the floor then maybe go for a cavity drain membrane as a damp proof membrane and accept if water comes in you will deal with it then.

If it is going to be habitable accommodation it needs to be totally dry with no water or water vapour acceptable. You have two choices.

A. Waterproofing an Existing Basement – Barrier Option

This barrier will require preparation by a trained waterproofing expert. To make it 100% watertight means 100% workmanship which keep in mind is very difficult to achieve. In all circumstances with an internal barrier, for it to be effective you will need to do not only the walls but also the floors. Make sure you have a good existing slab here or even a new one to make it effective. Bricks on edge or flags on soil will not do for habitable accommodation they will need to be removed and can be re-instated later.

B. Waterproofing an Existing Basement – Cavity Drain Option

This would be the recommended solution. A drained cavity system is ideal. When waterproofing an existing basement with this system you will have a series of dimpled sheet membranes (usually 8mm in depth) which are mechanically fixed back to the building fabric using a waterproof MultiPlug (plug with a waterproof seal which acts like a rawl plug that you can fix into) then depending upon the finish required either a plain 8mm membrane with battens on plugs or a frame work tied back into the plugs or a meshed dimpled sheet which you can render onto. These systems act as water management system in your existing basement, moving any moisture or water behind the dimples and down to a internal drain which are installed at the wall floor junction. The drain can then either feed out to an open elevation or to an existing drain or a sump and pump.

Prior to using either system here’s a quick guide to the pro's and cons of both.

Option A – Barrier

Disadvantages - Any applied system will need preparation to the substrate prior to application which can prove very disruptive and messy and a real problem in general. Depending upon the substrate you may have to rake out the mortar joints, sand blast, scabble, hack off to get back to the substrate and prepare it ready for the applied barrier.

Another disadvantage is that wet trades are introduced, as you are potentially making a wet project even more damp by introducing a wet solution. This introduces problems with the waterproof barrier in terms of drying times. Drying out times are one of the most frustrating elements of the barrier approach this can significantly impede a building programme especially when it comes to be able to decorate the finish project

A final disadvantage here is the inability to fix things like shelving units into the barrier without puncturing the barrier. This will also invalidate any guarantee that was offered by a professional installer.

Advantages - The biggest advantage with the barrier is if placed perfectly it will negate the need for installing any form of sump system which saves on future maintenance costs.

Option B – The Internal Drained Cavity System

Advantages – The drained cavity has many advantages the main ones being:

•Minimal surface preparation required, if any

•Can be installed with no wet trades or drying out times if designed correctly

•Can be decorated quickly if an independent dry lining frame is used

•Does not push water to other areas of the project – as could happen with a barrier

•Can be used on all Listed Buildings as it is fully reversible – barriers are not

Disadvantages - The biggest disadvantage is that if you are below invert level you will need to use a pump which will mean ongoing maintenance.

So there you are some very important things to consider when choosing your basement waterproofing technique. The most important thing really is to make sure whatever system you use put into the budget to get a professional waterproofing contractor to undertake the works. Contact the manufacturer and check that they know the installer and can recommend them. This way you will have a course of action should the system be installed poorly.

Read more about Newton System 500 Cavity Drain Membrane Solution (link ‘Newton System 500 Cavity Drain Membrane Solution’ to newton-membranes.co.uk/basement-waterproofing/

Further Information and Registered Installers

For further advice about waterproofing an existing basement or for a list of Newton Specialist Basement Contractors (NSBC) in your area, please ring Newtons on 020 7237 1217 or e-mail: info@newton-membranes.co.uk

When you are looking at waterproofing an existing basement you have a large variety of products available at your disposal. The real key is choosing the right product, the right preparation technique and for the right price to achieve the degree of waterproofing you need for your intended use of the basement.

So let's go through a quick guide for you to get the ball rolling. When waterproofing an existing basement, you are either going to:

1. Hold water back by applying a system to the basement such as cementitious slurry or similar or

2. Install a cavity drain system which will divert the water and get rid of it prior to damaging internal finishes.

Firstly what needs to be considered is – what are you using the space for? If it is a bike shed then you are not going to insulate it or go to a massive effort to rake out the mortar joints etc. The big cost will be the prep here and of course it will take a while for the render approach to dry. If you are happy with the risk of water ingress coming out on the floor then maybe go for a cavity drain membrane as a damp proof membrane and accept if water comes in you will deal with it then.

If it is going to be habitable accommodation it needs to be totally dry with no water or water vapour acceptable. You have two choices.

A. Waterproofing an Existing Basement – Barrier Option

This barrier will require preparation by a trained waterproofing expert. To make it 100% watertight means 100% workmanship which keep in mind is very difficult to achieve. In all circumstances with an internal barrier, for it to be effective you will need to do not only the walls but also the floors. Make sure you have a good existing slab here or even a new one to make it effective. Bricks on edge or flags on soil will not do for habitable accommodation they will need to be removed and can be re-instated later.

B. Waterproofing an Existing Basement – Cavity Drain Option

This would be the recommended solution. A drained cavity system is ideal. When waterproofing an existing basement with this system you will have a series of dimpled sheet membranes (usually 8mm in depth) which are mechanically fixed back to the building fabric using a waterproof MultiPlug (plug with a waterproof seal which acts like a rawl plug that you can fix into) then depending upon the finish required either a plain 8mm membrane with battens on plugs or a frame work tied back into the plugs or a meshed dimpled sheet which you can render onto. These systems act as water management system in your existing basement, moving any moisture or water behind the dimples and down to a internal drain which are installed at the wall floor junction. The drain can then either feed out to an open elevation or to an existing drain or a sump and pump.

Prior to using either system here’s a quick guide to the pro's and cons of both.

Option A – Barrier

Disadvantages - Any applied system will need preparation to the substrate prior to application which can prove very disruptive and messy and a real problem in general. Depending upon the substrate you may have to rake out the mortar joints, sand blast, scabble, hack off to get back to the substrate and prepare it ready for the applied barrier.

Another disadvantage is that wet trades are introduced, as you are potentially making a wet project even more damp by introducing a wet solution. This introduces problems with the waterproof barrier in terms of drying times. Drying out times are one of the most frustrating elements of the barrier approach this can significantly impede a building programme especially when it comes to be able to decorate the finish project

A final disadvantage here is the inability to fix things like shelving units into the barrier without puncturing the barrier. This will also invalidate any guarantee that was offered by a professional installer.

Advantages - The biggest advantage with the barrier is if placed perfectly it will negate the need for installing any form of sump system which saves on future maintenance costs.

Option B – The Internal Drained Cavity System

Advantages – The drained cavity has many advantages the main ones being:

•Minimal surface preparation required, if any

•Can be installed with no wet trades or drying out times if designed correctly

•Can be decorated quickly if an independent dry lining frame is used

•Does not push water to other areas of the project – as could happen with a barrier

•Can be used on all Listed Buildings as it is fully reversible – barriers are not

Disadvantages - The biggest disadvantage is that if you are below invert level you will need to use a pump which will mean ongoing maintenance.

So there you are some very important things to consider when choosing your basement waterproofing technique. The most important thing really is to make sure whatever system you use put into the budget to get a professional waterproofing contractor to undertake the works. Contact the manufacturer and check that they know the installer and can recommend them. This way you will have a course of action should the system be installed poorly.

Read more about Newton System 500 Cavity Drain Membrane Solution (link ‘Newton System 500 Cavity Drain Membrane Solution’ to newton-membranes.co.uk/basement-waterproofing/

Further Information and Registered Installers

For further advice about waterproofing an existing basement or for a list of Newton Specialist Basement Contractors (NSBC) in your area, please ring Newtons on 020 7237 1217 or e-mail: info@newton-membranes.co.uk

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

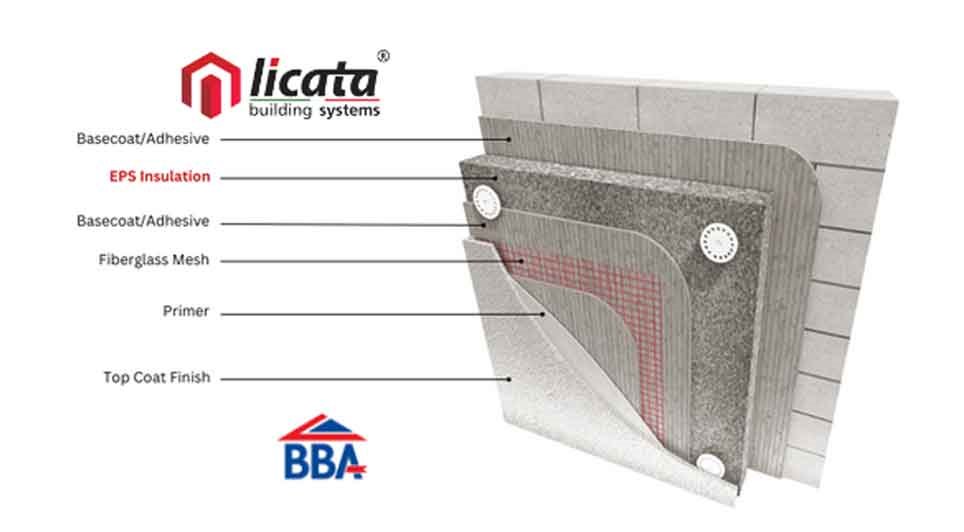

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London