Construction News

12/12/2012

Invizifix® Thermo-Ash (FSC Hardwood)

Ash hardwood would normally only be used for bespoke internal joinery projects, however, due to the Thermo process (Thermo-Ash) can now revolutionise the outdoor market bringing a high quality exclusivity to the discerning client who wants only the best.

Ecological

100% Natural

Free of Chemicals

Environmentally friendly and recyclable

Stability

Moisture content

Reduced Water absorption

Minimized Swelling, Bending & Splitting

Durability

25+years of Durability

Resins and sugars removed

Improved durability against fungus and insect attack

Highly durable against all weather conditions

Thermowood is a modification process with steam and high heat treatment. This process takes between 48 and 96 hours, taking into account some variables such as; timber species, width and initial moisture content.

Thermowood process can be divided into 3 stages; high temperature drying, heat treatment and cooling. Most of the negatives of wood are minimized and have been abolished.

As a result of the high temperature applied to the wood, the substances which shorten the lifecycle of any timber (glucose,citric acid, resin etc) which exist at the inner part of the wood are resolved and crystallized. This process makes the physical properties of the timber better, improves the durability and provides an excellent colour.

The reduced moisture content of the wood and relative humidity removed the Thermo-Ash, Thermo-Iroko and Thermo-Oak becomes very stable.

THERMOWOOD METHOD

1. Temperature increase and high temperature drying:

Wood temperature is raised rapidly using heat and steam to a level of around 100 deg C. Thereafter the temperature is increased steadily to 130 deg C and moisture content is reduced to almost zero.

2. Heat Treatment:

Whenever high heat drying is required the temperature is increased to a level of between 185 - 215 deg C. When the correct level is reached the temperature remains constant for 2-3 hours.

3. Cooling and Conditioning:

In this final stage, the temperature is reduced to 50-60 deg C by using a controlled water spraying system, this process continues until the moisture content reaches between 4% - 6%.

During this raising and lowering of the temperature, a special adjustment system is used in order to prevent the surface and inside from checking and spitting. These values differ depending on the species and dimensions.

Typical Uses

Because Ash is a tough timber it is used for sports equipment such as Oars, Bats and Cues. Handles for workshop tools and garden tools. Ash is also renowned for quality furniture, boatbuilding and paddles, interior joinery, built in kitchens and decorative veneers. Now thanks to the Thermo process, stable and durable exterior decking.

QTD's Unique Hidden INVIZIFIX® Profile

QTD's Exclusively designed edge profile virtually hides the fixing while still allowing you access to remove and replace a damaged or badly marked board.

Thus eliminating the need to cut out the offending board and face fix and plug the screw holes on a new one.

www.QualityTimberConstruction.co.uk

www.QualityTimberDecking.com

www.QualityTimberSupplies.com

Phone: 0118-932-8596

Mobile: 07801-887745

Ecological

100% Natural

Free of Chemicals

Environmentally friendly and recyclable

Stability

Moisture content

Reduced Water absorption

Minimized Swelling, Bending & Splitting

Durability

25+years of Durability

Resins and sugars removed

Improved durability against fungus and insect attack

Highly durable against all weather conditions

Thermowood is a modification process with steam and high heat treatment. This process takes between 48 and 96 hours, taking into account some variables such as; timber species, width and initial moisture content.

Thermowood process can be divided into 3 stages; high temperature drying, heat treatment and cooling. Most of the negatives of wood are minimized and have been abolished.

As a result of the high temperature applied to the wood, the substances which shorten the lifecycle of any timber (glucose,citric acid, resin etc) which exist at the inner part of the wood are resolved and crystallized. This process makes the physical properties of the timber better, improves the durability and provides an excellent colour.

The reduced moisture content of the wood and relative humidity removed the Thermo-Ash, Thermo-Iroko and Thermo-Oak becomes very stable.

THERMOWOOD METHOD

1. Temperature increase and high temperature drying:

Wood temperature is raised rapidly using heat and steam to a level of around 100 deg C. Thereafter the temperature is increased steadily to 130 deg C and moisture content is reduced to almost zero.

2. Heat Treatment:

Whenever high heat drying is required the temperature is increased to a level of between 185 - 215 deg C. When the correct level is reached the temperature remains constant for 2-3 hours.

3. Cooling and Conditioning:

In this final stage, the temperature is reduced to 50-60 deg C by using a controlled water spraying system, this process continues until the moisture content reaches between 4% - 6%.

During this raising and lowering of the temperature, a special adjustment system is used in order to prevent the surface and inside from checking and spitting. These values differ depending on the species and dimensions.

Typical Uses

Because Ash is a tough timber it is used for sports equipment such as Oars, Bats and Cues. Handles for workshop tools and garden tools. Ash is also renowned for quality furniture, boatbuilding and paddles, interior joinery, built in kitchens and decorative veneers. Now thanks to the Thermo process, stable and durable exterior decking.

QTD's Unique Hidden INVIZIFIX® Profile

QTD's Exclusively designed edge profile virtually hides the fixing while still allowing you access to remove and replace a damaged or badly marked board.

Thus eliminating the need to cut out the offending board and face fix and plug the screw holes on a new one.

www.QualityTimberConstruction.co.uk

www.QualityTimberDecking.com

www.QualityTimberSupplies.com

Phone: 0118-932-8596

Mobile: 07801-887745

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

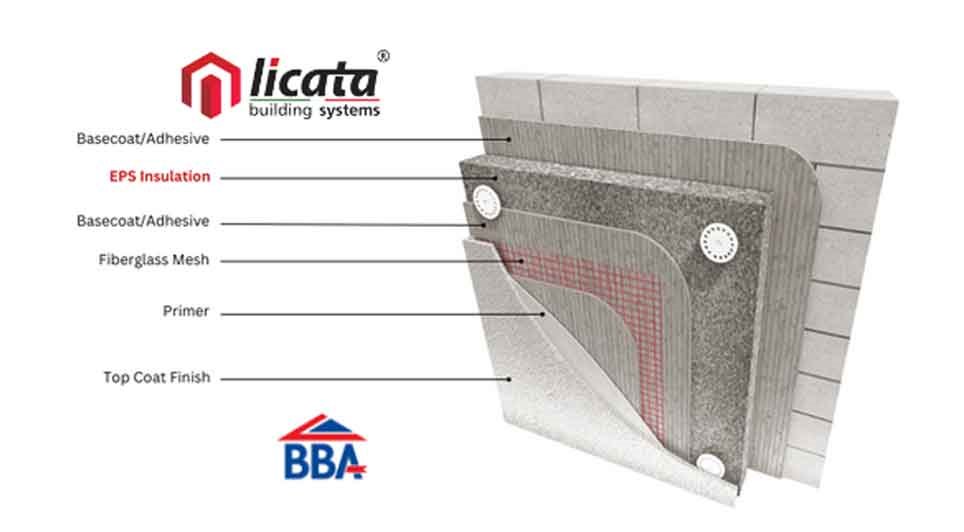

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London