Construction News

27/10/2014

The Legal Position On Safety Surfacing

DCM Surfaces are frequently asked whether or not it is a legal requirement to install safety surfacing at schools, nurseries and other playground areas. The truth is that in fact there is no law which states that safety surfacing must be installed however, it is highly recommended by a number of professionals.

Top safety organisations such as RoSPA, BSI, NPFA and CAPT highly recommend the installation of safety surfaces. Firstly, to help protect children from injury should they slip, trip or fall when using the surface but secondly to also protect those in charge from any potential personal injury claims which could be lodged against them as a result of injury.

Unfortunately we currently live in a “claims culture” where some people will make exaggerated claims of personal injury in order to wrongly obtain compensation. Whilst there are genuine claims for personal injury it’s these fraudulent claims which nursery owners, schools and playground owners need to protect themselves against.

The Department of the Environment ‘strongly recommended’ its use in 1978 while the Department of Culture, Media and Sport (currently the Government’s lead body on playgrounds) advised its use in their Playground Safety Guidelines (1993) as one of the design elements of a safe playground. The Health and Safety Executive has also recommended it.

Many courts are now recognising wet pour safety surfacing as good practice, there has been an increase in the number of out-of-court settlements which have arisen from playground accidents and this would suggest that more and more courts recognise safety surfacing as good practice, especially when placed under new equipment.

Injury often occurs as a result of children having an inquisitive nature, more often than not they will find new and exciting ways to use play equipment and this isn’t always the way in which it’s intended to be used as outlined by a playground manufacturer.

When injury does occur it can be very upsetting for a child, whether it’s a bump, bruise, cut or even something more severe and life threatening. Common playground injuries include fractures, broken bones, internal injuries, concussion, dislocations and even in some cases amputation.

Although playground design, equipment installation and equipment maintenance are all important factors; safety surfaces too should be given careful consideration.

Wet pour safety surfacing is strongly recommended when installed correctly once the critical fall height has been properly calculated.

Hard surfaces should be avoided, but if you are unsure then make sure that you speak to experts within the industry and they can advise you. Safety surfaces must have the ability to absorb shock and therefore installation for prevention of injury is strongly recommended.

Top safety organisations such as RoSPA, BSI, NPFA and CAPT highly recommend the installation of safety surfaces. Firstly, to help protect children from injury should they slip, trip or fall when using the surface but secondly to also protect those in charge from any potential personal injury claims which could be lodged against them as a result of injury.

Unfortunately we currently live in a “claims culture” where some people will make exaggerated claims of personal injury in order to wrongly obtain compensation. Whilst there are genuine claims for personal injury it’s these fraudulent claims which nursery owners, schools and playground owners need to protect themselves against.

The Department of the Environment ‘strongly recommended’ its use in 1978 while the Department of Culture, Media and Sport (currently the Government’s lead body on playgrounds) advised its use in their Playground Safety Guidelines (1993) as one of the design elements of a safe playground. The Health and Safety Executive has also recommended it.

Many courts are now recognising wet pour safety surfacing as good practice, there has been an increase in the number of out-of-court settlements which have arisen from playground accidents and this would suggest that more and more courts recognise safety surfacing as good practice, especially when placed under new equipment.

Injury often occurs as a result of children having an inquisitive nature, more often than not they will find new and exciting ways to use play equipment and this isn’t always the way in which it’s intended to be used as outlined by a playground manufacturer.

When injury does occur it can be very upsetting for a child, whether it’s a bump, bruise, cut or even something more severe and life threatening. Common playground injuries include fractures, broken bones, internal injuries, concussion, dislocations and even in some cases amputation.

Although playground design, equipment installation and equipment maintenance are all important factors; safety surfaces too should be given careful consideration.

Wet pour safety surfacing is strongly recommended when installed correctly once the critical fall height has been properly calculated.

Hard surfaces should be avoided, but if you are unsure then make sure that you speak to experts within the industry and they can advise you. Safety surfaces must have the ability to absorb shock and therefore installation for prevention of injury is strongly recommended.

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

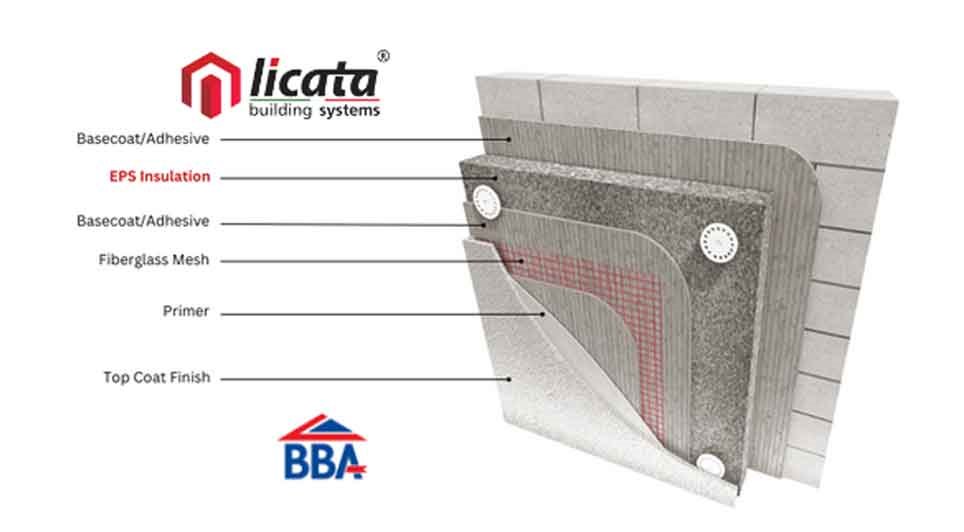

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London