Construction News

28/06/2017

The New Princess Royal Grandstand At Cheltenham Racecourse

Cheltenham Racecourse is situated in Prestbury on the outskirts of the historic spa town of Cheltenham. The Home of Jump Racing, Cheltenham Racecourse is the venue for the world's pre-eminent Jump meeting, "The Festival", which takes place in March over four days every year. The racecourse is set against the beautiful backdrop of the Cotswolds and is a stunning natural arena which enjoys great vistas.

The Jockey Club, had predetermined that after the "The Festival" in 2014 that they wanted to significantly re-develop their Cheltenham Course facilities for race-goers before the start of the new season and with minimal interruptions as possible. This huge expansion of facilities is part of a £400M nationwide capital investment programme in their national venues to bolster interest in the sport and provide first class services for their customers.

In addition to the Princess Royal Grandstand, other projects were outlined for completion, including a refurbished weighing room, a new first aid room and the new crescent walkway which was opened for the Showcase meeting and greatly assists race-goers' mobility behind the grandstand and offers additional viewing of the parade ring too.

Amber Precast Limited have been working collaboratively alongside Roy Geddes Bricks Ltd, Kier Construction and Roberts Limbrick Architects on the design and production of the Precast Stone requirements for the new Princess Royal Grandstand at the Cheltenham Racecourse.

Amber Precast Cast Stone features as a prominent part of the architectural design of the new grandstand facilities.

The huge £45M project is a multi-phased development programme of 14 integrated construction projects conducted over the last 19 months. The project is the largest of its kind by the Jockey Club. It will provide a magnificent five and a half storey centre-piece grandstand for everyone to enjoy and features dry cast stone throughout many aspects of the design of the stand, its façade and the stepped arena areas used for public viewing.

The official opening was conducted by Princess Anne, The Princess Royal at 11.30am on Friday, 13 November.

Ian Renton, Regional Director for Cheltenham and the South West, The Jockey Club, commented: "The team and I could not be more excited that we are to open the new grandstand at Cheltenham on the first day of The Open. It is a huge credit to our team at Cheltenham together with our contractors that we have been able to continue with a complete racing programme whilst undertaking a development on this scale. I am delighted that all those involved with the redevelopment so successfully met the logistical challenge to ensure that our race-goers were not inconvenienced last season."

Celebrating this great occasion, Managing Director of Amber Precast, Mr Mark Johnson said: "I'm particularly pleased and immensely proud of our team's involvement in this auspicious project. It's a true reflection of how far we have come as a business in the last 25 years and testament to our recent growth in providing large scale construction solutions that feature grand designs of significant architectural merit.

"In recent times, we have fully embraced new larger scale UK based infrastructure projects in Precast Concrete and Cast Stone and it's a real privilege for the company to make this "Royal" connection with the build of the new Princess Royal Stand at Cheltenham Racecourse."

Amber Precast was selected as the preferred main supplier out of a number of hopeful Precast Companies eager to be involved this important and prestigious construction project. The project was won on the strength of their financial standing as the leading "construction component" of the Hughes Armstrong Group, their expertise & professionalism, ability to manage a project of this size and complexity and ability to deliver added value and quality to the project through its industry acclaimed Project Managers. Amber Precast offered their clients Roy Geddes Bricks Ltd a Dry and Wet Cast solution to meet the needs of this spectacular build.

The original Centaur Building at Cheltenham Racecourse was made from ashlar and the project required a solution that would both complement the existing building with professional colour matching to provide a new center piece construction around the Winners Enclosure.

Project Manager and Managing Director of Amber Precast, Mark Johnson explains: "The solution was to work out to the exact millimetre – the entire jigsaw of 32,000 Cast Stone pieces, create it in a virtual 3D environment using the latest CAD technology, manufacture everything offsite and supply it in the sequence it was to be built, over a period of 19 months with numerous "on-time" deliveries direct to site to suit the speed of the installation schedule. I am pleased to say that we did so, both ahead of time and within budget."

The CAD solution took hundreds of man hours to create and detailed the exact placement of all 32,000 stone pieces virtualised over a range of 200 plus CAD drawings producing over 200 separate Cast Stone Moulds which made up all the individual standard and bespoke casting components of the Princess Royal Grandstand.

Amber Precast supplied the majority of the ashlar colour matched Cast Stone work of the Princess Royal Grandstand, which was also utilised in creation of The Horse Bridge, Horse Statues, retaining walls, raised planters and the block work that formed the basis of much of external base construction components.

The entire project has taken over half a million man hours to complete the onsite installation alone.

The new Princess Royal Grandstand has a capacity of 7,000 guests and public viewing steppings to accommodate up to 3,000 spectators alongside catering and hospitality facilities throughout including Big Buck's Champagne Bar, other new bars, toilets, restaurants, the new Royal Box, private boxes and viewing facilities for Owners, Jockey's and all Cheltenham race-goers.

The Amber Precast Cast Stone features are a very prominent part of the aesthetics of the new facilities and provide a solid foundation to display the overall design intent and they will continue to be enjoyed by members of the public, VIP's, foreign dignitaries and Royalty alike for many years to come.

For more information, visit www.amberprecast.co.uk

The Jockey Club, had predetermined that after the "The Festival" in 2014 that they wanted to significantly re-develop their Cheltenham Course facilities for race-goers before the start of the new season and with minimal interruptions as possible. This huge expansion of facilities is part of a £400M nationwide capital investment programme in their national venues to bolster interest in the sport and provide first class services for their customers.

In addition to the Princess Royal Grandstand, other projects were outlined for completion, including a refurbished weighing room, a new first aid room and the new crescent walkway which was opened for the Showcase meeting and greatly assists race-goers' mobility behind the grandstand and offers additional viewing of the parade ring too.

Amber Precast Limited have been working collaboratively alongside Roy Geddes Bricks Ltd, Kier Construction and Roberts Limbrick Architects on the design and production of the Precast Stone requirements for the new Princess Royal Grandstand at the Cheltenham Racecourse.

Amber Precast Cast Stone features as a prominent part of the architectural design of the new grandstand facilities.

The huge £45M project is a multi-phased development programme of 14 integrated construction projects conducted over the last 19 months. The project is the largest of its kind by the Jockey Club. It will provide a magnificent five and a half storey centre-piece grandstand for everyone to enjoy and features dry cast stone throughout many aspects of the design of the stand, its façade and the stepped arena areas used for public viewing.

The official opening was conducted by Princess Anne, The Princess Royal at 11.30am on Friday, 13 November.

Ian Renton, Regional Director for Cheltenham and the South West, The Jockey Club, commented: "The team and I could not be more excited that we are to open the new grandstand at Cheltenham on the first day of The Open. It is a huge credit to our team at Cheltenham together with our contractors that we have been able to continue with a complete racing programme whilst undertaking a development on this scale. I am delighted that all those involved with the redevelopment so successfully met the logistical challenge to ensure that our race-goers were not inconvenienced last season."

Celebrating this great occasion, Managing Director of Amber Precast, Mr Mark Johnson said: "I'm particularly pleased and immensely proud of our team's involvement in this auspicious project. It's a true reflection of how far we have come as a business in the last 25 years and testament to our recent growth in providing large scale construction solutions that feature grand designs of significant architectural merit.

"In recent times, we have fully embraced new larger scale UK based infrastructure projects in Precast Concrete and Cast Stone and it's a real privilege for the company to make this "Royal" connection with the build of the new Princess Royal Stand at Cheltenham Racecourse."

Amber Precast was selected as the preferred main supplier out of a number of hopeful Precast Companies eager to be involved this important and prestigious construction project. The project was won on the strength of their financial standing as the leading "construction component" of the Hughes Armstrong Group, their expertise & professionalism, ability to manage a project of this size and complexity and ability to deliver added value and quality to the project through its industry acclaimed Project Managers. Amber Precast offered their clients Roy Geddes Bricks Ltd a Dry and Wet Cast solution to meet the needs of this spectacular build.

The original Centaur Building at Cheltenham Racecourse was made from ashlar and the project required a solution that would both complement the existing building with professional colour matching to provide a new center piece construction around the Winners Enclosure.

Project Manager and Managing Director of Amber Precast, Mark Johnson explains: "The solution was to work out to the exact millimetre – the entire jigsaw of 32,000 Cast Stone pieces, create it in a virtual 3D environment using the latest CAD technology, manufacture everything offsite and supply it in the sequence it was to be built, over a period of 19 months with numerous "on-time" deliveries direct to site to suit the speed of the installation schedule. I am pleased to say that we did so, both ahead of time and within budget."

The CAD solution took hundreds of man hours to create and detailed the exact placement of all 32,000 stone pieces virtualised over a range of 200 plus CAD drawings producing over 200 separate Cast Stone Moulds which made up all the individual standard and bespoke casting components of the Princess Royal Grandstand.

Amber Precast supplied the majority of the ashlar colour matched Cast Stone work of the Princess Royal Grandstand, which was also utilised in creation of The Horse Bridge, Horse Statues, retaining walls, raised planters and the block work that formed the basis of much of external base construction components.

The entire project has taken over half a million man hours to complete the onsite installation alone.

The new Princess Royal Grandstand has a capacity of 7,000 guests and public viewing steppings to accommodate up to 3,000 spectators alongside catering and hospitality facilities throughout including Big Buck's Champagne Bar, other new bars, toilets, restaurants, the new Royal Box, private boxes and viewing facilities for Owners, Jockey's and all Cheltenham race-goers.

The Amber Precast Cast Stone features are a very prominent part of the aesthetics of the new facilities and provide a solid foundation to display the overall design intent and they will continue to be enjoyed by members of the public, VIP's, foreign dignitaries and Royalty alike for many years to come.

For more information, visit www.amberprecast.co.uk

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

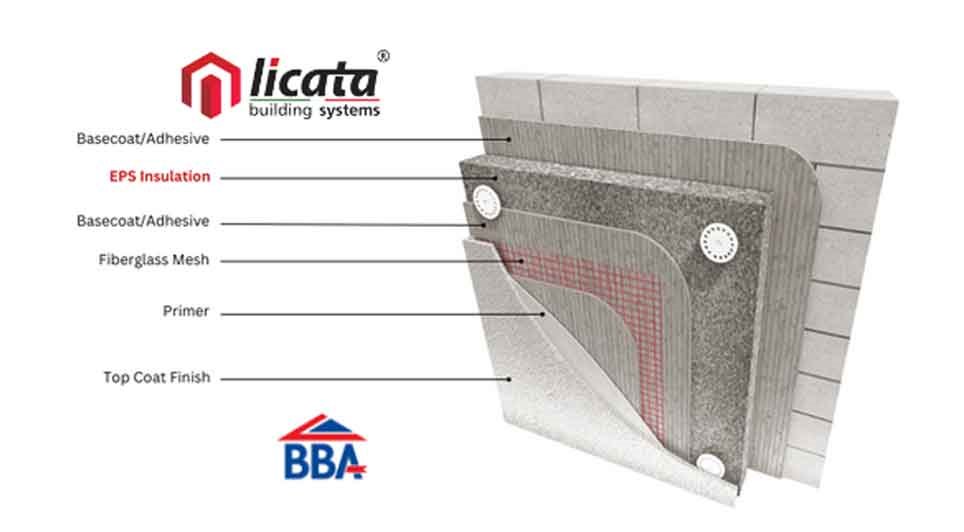

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London