In the 45 years since the first introduction of fabric-based air dispersion technology the concept has been developed and refined, but the primary differences between fabric and metal-based HVAC/R solutions are still founded on comfort, hygiene, efficiency and savings.

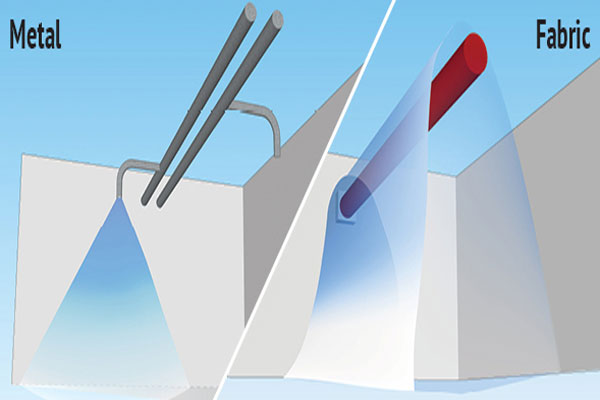

Conventional metal ducting uses spot diffusion, which creates stagnant air zones, unpleasant drafts and inconvenient noise pollution. From a comfort perspective this is the primary difference between metal solutions and FabricAir dispersion technology.

From a hygienic perspective, the condensation-free nature of fabric ducts diminishes the risk of microbial growth inside or on the ducting. Specific fabrics even have Cleanroom 3 certification. The fabrics are created in woven polyester fibers, which ensures that the ducts can be washed, even sterilized in an autoclave, without causing negative impact on their performance.

The initial advantage of fabric air dispersion technology was twofold: Eliminating drafts created a more healthy work environment, thus lowering the number of absences; and creating better airflow patterns resulted in a more even air distribution and lower temperature gradients in the meat processing plants where the technology was first applied. The latter has been an area of thorough research, which had led to a wide array of flow models that can be combined to optimize induction in any given project. This is part of what makes the technology more efficient than conventional metal solutions.

Surface flow models enable high air changes at low velocity, which is good for low ceiling applications and comfort. Directional flow models enable precise longer throws to create better induction in e.g. industrial production or high storage applications. May applications require unique combinations of airflow patterns to create the ideal air dispersion solution and using fabrics this is a straightforward creation process.

Through the use of proprietary 3D software and CFD modelling, air engineering experts design a solution specifically for a given project optimizing the airflow patterns based on the relevant parameters of the application and project specifics. Once the drawings are approved by the customers, the duct solution is tailored and shipped, arriving on site typically in less than 14 days, ready to install. This is another significant difference and an important efficiency aspect; the quickest lead times on the market.

Ease of installation is a hallmark of the technology. Instead of juggling huge, heavy steel duct pieces, the installer simply screws the rail onto the ceiling and slides the fabric ducts in place. No need for on-site attenuation, no grills or diffusors, no insulation or painting and no need for balancing. Installing a fabric-based solution is four to five times quicker than installing a metal-based solution; thus, depending on local labor costs the savings potential is significant – up to 70%.

With textile-based air dispersion technology, the air is distributed evenly across the room at low velocity, thus avoiding drafts, dead zones and minimizing noise (<30NC) for higher comfort. With permeable fabrics, no condensation is formed on or inside the ducts, even if the inlet temperature is below the dew point. This prevents bacterial growth and mold for a more hygienic indoor environment. The bespoke solutions ensure better dispersion patterns and higher efficiency with lower pressure drops. Contrary to metal ducting, fabric ducts only require simple tools, such as a screwdriver, to install, which entails significant cost savings. Those are the four primary technological difference between fabric and metal air dispersion solutions.

www.fabricair.com

Construction News

05/09/2018

Differences Between Metal And Fabric Air Dispersion Technology

07/07/2025

Travelodge has officially broken ground on a new 100-room hotel in Loughton, marking the latest addition to the UK's first budget hotel brand's expanding portfolio.

The company, which operates more than 610 hotels across the UK, Ireland and Spain, is aiming to meet growing demand for affordable ac

07/07/2025

Oldham Council has officially unveiled Snipe Gardens, a newly created green space and pedestrian gateway designed to provide a welcoming entrance into the town centre.

Situated on the site of the former Snipe Inn pub, the new landscaped area links Oldham bus station with Henshaw Street. As one of t

07/07/2025

Manuela Perteghella, MP for Stratford-upon-Avon, has visited Severn Trent’s Milcote Sewage Treatment Works to learn more about the complex processes involved in wastewater treatment and see firsthand how a major infrastructure upgrade is progressing.

The Milcote site, which serves approximately 70,

07/07/2025

A series of major road resurfacing projects are set to take place across Leicester during the school summer holidays, as part of a £1 million programme aimed at improving the city's road network.

Leicester City Council has scheduled the works during the school break to minimise disruption, taking a

07/07/2025

Preston's landmark cultural institution, The Harris, will officially reopen to the public on Sunday, 28 September 2025, following a major £19 million transformation.

The restoration, delivered through the Harris Your Place project, was made possible through funding from Preston City Council, The Na

07/07/2025

A major investment deal has been finalised to deliver nearly 1,000 high-quality rental homes in Digbeth, Birmingham.

Aviva Capital Partners and Moda Group have partnered with NatWest, Homes England, and the West Midlands Combined Authority (WMCA) to fund the £200m+ Stone Yard development—set to tra

07/07/2025

Luxury housebuilder Consero has received planning permission from Guildford Borough Council to deliver a boutique development of high-end homes in the sought-after Surrey village of Send.

The project, named Oaktrees, will see the demolition of an existing 1960s six-bedroom detached house on Clandon

07/07/2025

Passengers using Petts Wood station in south east London are being advised to prepare for changes to station access as essential refurbishment work on the station's footbridge begins in August 2025.

The major upgrade project, aimed at extending the life of the footbridge and ensuring it remains saf

07/07/2025

Story Homes has teamed up with luxury homeware brand DUSK to unveil a new view home at its Tithe Gardens development in Poulton-le-Fylde.

The Spencer, a popular three-bedroom house type, has been fully styled by DUSK and will open to visitors on Saturday, 12 July.

This partnership brings together

07/07/2025

Morgan Sindall Construction has officially begun renovation works on the Claycroft Residences at the University of Warwick, one of the largest accommodation complexes on the university’s main campus in Coventry.

The extensive 17,000m² project will transform three individual accommodation blocks, wh

UK

UK Ireland

Ireland Scotland

Scotland London

London