Fronius is upgrading its TransSteel series with the addition of the pulse function. Not only does the pulsed arc allow faster welding speeds on thicker materials, but rework is reduced as the pulsed arc causes less welding spatter.

The pulse mode makes it possible to bypass the intermediate arc, which is difficult to control and prone to spatter. The resulting reduction in spattering leads to up to 70 percent less rework. Furthermore, the pulsed arc allows welding speeds that are up to 30 percent higher to be achieved. All these advantages are now also available from the Fronius TransSteel 3000 compact as well as the TransSteel 4000 and 5000.

Pulse tacking to avoid distortion

The TransSteel devices were developed especially for use on steel. The addition of the pulse function now makes these power sources true all-rounders, as a wide range of functions supports the welder in various applications. With the help of the spot function, even and consistent welding spots can be produced – ideal for tacking workpieces. Interval welding not only produces a rippled seam appearance, but the lower heat input also reduces the possibility of material distortion on light gage sheets.

Special characteristics ensure the user has the ideal arc properties at their disposal. The "Steel" universal characteristics are particularly suitable for simple and fast welding applications. "Steel Root" has been developed for root welding and also provides a soft and stable dip transfer arc for good gap-bridging ability over wide gaps. The "Steel Dynamic" welding program, on the other hand, produces a particularly hard and concentrated arc, thus achieving high welding speeds and deep penetration. Where minimal spattering and deep penetration are the order of the day, the TransSteel Pulse models with "Pulse Controlled Spray Arc" provide the perfect settings. With the "SynchroPulse", the welding power alternates between two operating points at a frequency of up to 5 Hertz. As the change between high and low current facilitates welding in a vertical up position, for example, it is possible to produce a pronounced seam rippling on aluminum alloys.

Three power categories, two models, one solution

The intuitive operating concept of the TransSteel allows immediate commissioning of the device without any previous knowledge. All the necessary welding parameters can be set on the front panel. A simple option for documenting the welding data completes the device concept. A USB thumb drive can be connected to the rear of the power source to store all important data – including time and device-related data, but also the parameters used such as current, voltage, and wire speed.

Fronius has added the pulse function to three models. The TransSteel 3000 compact Pulse is a multiprocess device that masters all three welding processes to the same high degree. The compact unit is ideal for a wide range of welding tasks on the construction site, in the workshop, or for repair work. For recurring welding tasks or in small series production, the pulse function on the TransSteel 4000 Pulse and TransSteel 5000 Pulse brings more options and speed. In contrast to the Compact version, these higher-power units have a separate wirefeeder.

blog.perfectwelding.fronius.com

Construction News

04/09/2020

Pulse Welding With Fronius TransSteel Pulse

23/05/2025

Railpen has appointed Skanska as the main contractor for Botanic Place, a landmark £242 million commercial office development set to transform the heart of Cambridge.

Skanska will lead both the construction and mechanical & electrical engineering services fit-out for the two-building scheme, delive

23/05/2025

East Midlands Airport (EMA) has announced ambitious plans to unlock over 50 hectares of airfield land for development, a move that could generate more than 20,000 new jobs.

The strategic blueprint was unveiled at UKREiiF, the UK's premier real estate investment and infrastructure forum in Leeds, wh

23/05/2025

Passengers travelling between London Euston and Scotland via the West Coast Main Line are being advised to plan ahead, as a major stretch of the railway between Rugby and Stafford will be closed for essential upgrades from Saturday 24 May to Sunday 1 June.

Network Rail will use the nine-day closure

23/05/2025

A new vision to revitalise Droylsden has been unveiled, with Tameside Council formally approving a long-term masterplan aimed at transforming the town centre into a vibrant, green, and sustainable community hub.

Developed with extensive input from local residents and stakeholders, the masterplan ou

23/05/2025

IM Properties has submitted a planning application for a £343 million state-of-the-art employment park, named Thrive, aimed at driving economic growth and securing advanced manufacturing, R&D, and logistics jobs across the region.

The proposal by the Midlands-based property developer outlines a 135

23/05/2025

Stepnell is reinforcing its reputation as a leading higher education specialist in Oxfordshire through a series of major projects with the University of Oxford and Oxford Brookes University.

Currently, Stepnell is undertaking a £3.3 million refurbishment at the University of Oxford’s Henry Wellcome

23/05/2025

More than 70 employees from Beard Construction offices across the South of England came together at the company's 194-acre Wrington Warren woodland near Bristol to plant over 130 trees, marking the completion of the first phase of a major woodland management plan.

The initiative forms part of Beard

23/05/2025

Rapid Energy, a leading UK provider of temporary heating and cooling solutions, is pleased to announce the appointment of Matt Stapley as its new Technical Director.

This strategic addition to the leadership team underscores the company's commitment to technical excellence and innovation in the HV

22/05/2025

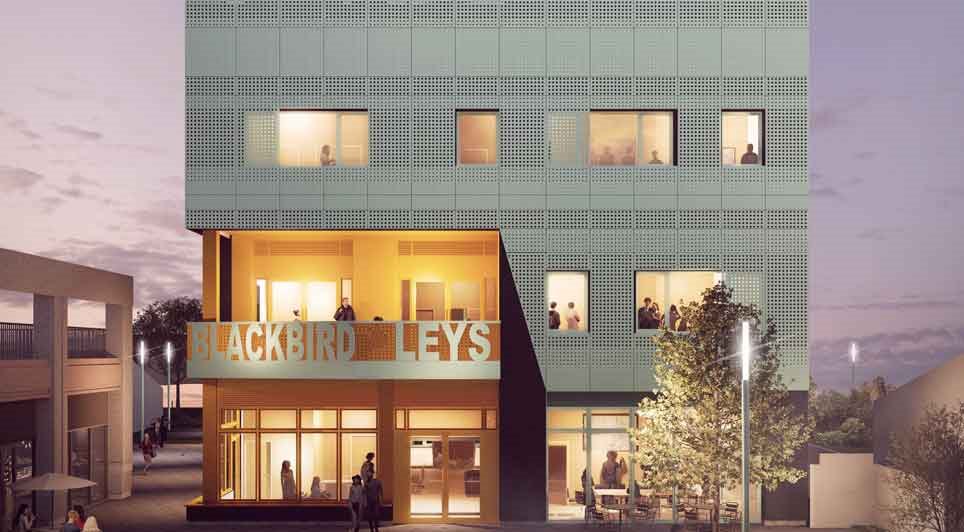

Oxford City Council has approved plans for a new, modern community centre in the heart of Blackbird Leys.

The council's planning committee gave the go-ahead on Tuesday 20 May, paving the way for construction to begin later this year.

The new centre is part of a broader redevelopment of the Distric

22/05/2025

Leading construction and facilities management company GRAHAM has officially commenced a new repairs and maintenance contract with Sandwell Property Care, part of the Council's Corporate Landlord team.

The contract covers the borough's extensive portfolio of non-housing properties, and will see GRA

UK

UK Ireland

Ireland Scotland

Scotland London

London