Construction News

04/11/2020

HS2 Reveals Onboard Robot

HS2 has revealed the use of an innovative onboard robot that will improve safety and efficiency on the high speed rail project's first two giant tunnelling machines, set to launch early next year.

Pioneered by HS2's main works contractor, Align, the Krokodyl robot is the first of its kind anywhere in the world and will be installed in the two tunnel boring machines (TBMs) that will be used to bore the 10 mile (16km) long Chiltern tunnels.

The Krokodyl robot, working in a similar manner to the robotic arms used in a car factory production line, will carry out simple repetitive tasks – removing wooden spacers between tunnel segments and inserting connection dowels – that people would normally do.

Each of the segments weighs up to eight tonnes and are delivered to the TBM with wooden spacers between them which are generally removed by hand. By fully automating this process, the Krokodyl removes the need for people to work in this potentially hazardous area and helps with the installation of the 112,000 tunnel segments.

The tunnel segments are erected – as the TBM moves forward – in order to form a structural water tight ring designed to support the ground loads.

A second feature of the robot, known as the Dobydo, then places the dowels into position ready for the segment to be slotted into place. Again, by automating this process, the robot reduces risk to people and improve safety and efficiency.

The Align joint venture – a team made up of Bouygues Travaux Publics, Sir Robert McAlpine, and VolkerFitzpatrick – built on their experience of delivering major tunnelling project across the world to develop the Krokodyl.

Eddie Woods, HS2 Ltd’s Head of Tunnelling said: "Safety is a key priority for HS2 and the introduction of these innovations that essentially remove personnel from harm’s way, is an excellent example of the sort of initiatives we are pleased to see implemented on the project. It is one of the ways that 'safe at heart' can be achieved by minimising exposure in high risk locations."

Didier Jacques, Align's Underground Construction Director said: "Safety is a key value that is shared by everyone working on HS2, including the client, Align itself and our supply chain partners. A lot of work has been undertaken by all concerned that has enabled us to develop and introduce this robot, thereby reducing the risk to our personnel, operating in our state of the art TBMs. We are very proud of these innovations which we would be happy to share with tunnelling teams working on other projects across the world, to help reduce the likelihood of accidents and injuries."

Pioneered by HS2's main works contractor, Align, the Krokodyl robot is the first of its kind anywhere in the world and will be installed in the two tunnel boring machines (TBMs) that will be used to bore the 10 mile (16km) long Chiltern tunnels.

The Krokodyl robot, working in a similar manner to the robotic arms used in a car factory production line, will carry out simple repetitive tasks – removing wooden spacers between tunnel segments and inserting connection dowels – that people would normally do.

Each of the segments weighs up to eight tonnes and are delivered to the TBM with wooden spacers between them which are generally removed by hand. By fully automating this process, the Krokodyl removes the need for people to work in this potentially hazardous area and helps with the installation of the 112,000 tunnel segments.

The tunnel segments are erected – as the TBM moves forward – in order to form a structural water tight ring designed to support the ground loads.

A second feature of the robot, known as the Dobydo, then places the dowels into position ready for the segment to be slotted into place. Again, by automating this process, the robot reduces risk to people and improve safety and efficiency.

The Align joint venture – a team made up of Bouygues Travaux Publics, Sir Robert McAlpine, and VolkerFitzpatrick – built on their experience of delivering major tunnelling project across the world to develop the Krokodyl.

Eddie Woods, HS2 Ltd’s Head of Tunnelling said: "Safety is a key priority for HS2 and the introduction of these innovations that essentially remove personnel from harm’s way, is an excellent example of the sort of initiatives we are pleased to see implemented on the project. It is one of the ways that 'safe at heart' can be achieved by minimising exposure in high risk locations."

Didier Jacques, Align's Underground Construction Director said: "Safety is a key value that is shared by everyone working on HS2, including the client, Align itself and our supply chain partners. A lot of work has been undertaken by all concerned that has enabled us to develop and introduce this robot, thereby reducing the risk to our personnel, operating in our state of the art TBMs. We are very proud of these innovations which we would be happy to share with tunnelling teams working on other projects across the world, to help reduce the likelihood of accidents and injuries."

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

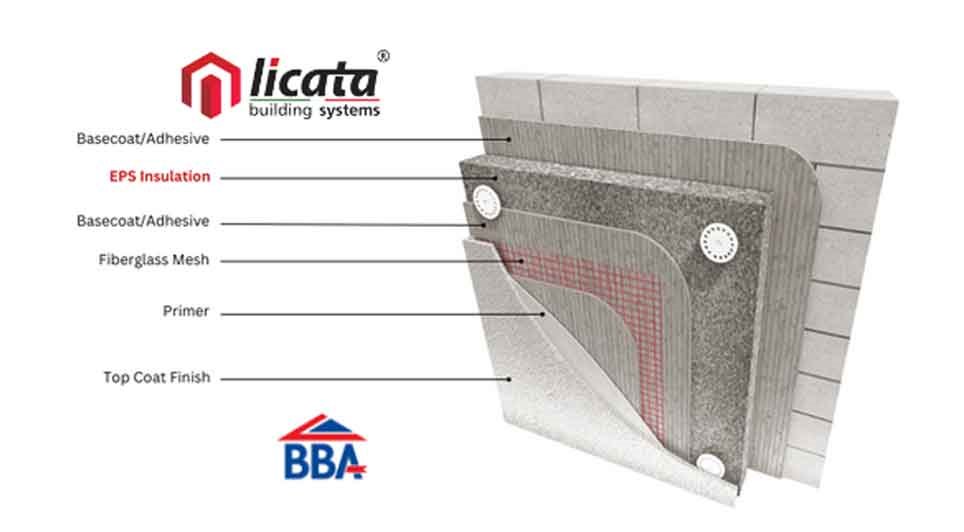

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London