Construction News

30/11/2020

Chemique Adhesives Helps Boost Efficiency For Garden Room Manufacturer

Future Rooms based near Gloucester, design, manufacture and install a stunning range of garden rooms that create space and style in any garden.

Their garden rooms offer a low maintenance, easily installed, cost-effective solution to improving a home by creating additional family or leisure space.future rooms

Until recently, Future Rooms were buying SIP panels that were ready built from an outside source. A SIP Panel, or sandwich panel as they are also known, is an insulating layer of rigid core insulation adhered to two layers of structural board. It is then pressed together under a uniform force until the adhesive has set, resulting in an extremely strong structural insulated panel (SIP).

In 2019, Future Rooms decided to take full control of their production costs and build their own SIP panels onsite, which are used in the manufacture of their garden room and office range.

"We wanted a partner that could offer a complete package to assist us in manufacturing the panels," explained Richard Kocerhan, Owner and MD of Future Rooms. "Chemique were able to provide extensive knowledge in panel lamination, recommend the correct adhesive, as well as supply the most suitable adhesive application equipment for the job."

"Following an initial meeting, it became apparent that a degree of semi-automation was required for making the panels and so we trialled our portable rake system in conjunction with a single component, moisture curing polyurethane adhesive from our Solfre range," said Phil Carter, Chemique Adhesives Business Development Manager.

This was the perfect combination and allowed Future Rooms to efficiently produce high quality laminated panels with an easy to use and cost-effective dispensing system. This method also reduces waste and is much cleaner and user friendly compared to more traditional methods of manual application.

The adhesive used with the rake system is Solfre1 – a single component, solvent-free polyurethane product. Solfre1 is suitable for a variety of applications such as construction panels, truck building, caravan panels and many similar uses where a permanent structural bond is required. Its unique formulation provides superior resistance to chemicals, heat, humidity and thermal shock.

Chemique Adhesives also has a team of service engineers on hand, providing assurance that in the event of a breakdown, this can be dealt with quickly and efficiently. The company's Total Service Package includes tailor-made adhesive solutions combined with full engineering and technical support. Service contracts are also available for added peace of mind.

For further details on our Solfre range or any of our adhesive application equipment then please get in touch - CLICK HERE

For further details about Future Rooms please visit: www.futurerooms.co.uk/

Or to find out more about installation, please visit: www.futuresips.co.uk/installation/

Their garden rooms offer a low maintenance, easily installed, cost-effective solution to improving a home by creating additional family or leisure space.future rooms

Until recently, Future Rooms were buying SIP panels that were ready built from an outside source. A SIP Panel, or sandwich panel as they are also known, is an insulating layer of rigid core insulation adhered to two layers of structural board. It is then pressed together under a uniform force until the adhesive has set, resulting in an extremely strong structural insulated panel (SIP).

In 2019, Future Rooms decided to take full control of their production costs and build their own SIP panels onsite, which are used in the manufacture of their garden room and office range.

"We wanted a partner that could offer a complete package to assist us in manufacturing the panels," explained Richard Kocerhan, Owner and MD of Future Rooms. "Chemique were able to provide extensive knowledge in panel lamination, recommend the correct adhesive, as well as supply the most suitable adhesive application equipment for the job."

"Following an initial meeting, it became apparent that a degree of semi-automation was required for making the panels and so we trialled our portable rake system in conjunction with a single component, moisture curing polyurethane adhesive from our Solfre range," said Phil Carter, Chemique Adhesives Business Development Manager.

This was the perfect combination and allowed Future Rooms to efficiently produce high quality laminated panels with an easy to use and cost-effective dispensing system. This method also reduces waste and is much cleaner and user friendly compared to more traditional methods of manual application.

The adhesive used with the rake system is Solfre1 – a single component, solvent-free polyurethane product. Solfre1 is suitable for a variety of applications such as construction panels, truck building, caravan panels and many similar uses where a permanent structural bond is required. Its unique formulation provides superior resistance to chemicals, heat, humidity and thermal shock.

Chemique Adhesives also has a team of service engineers on hand, providing assurance that in the event of a breakdown, this can be dealt with quickly and efficiently. The company's Total Service Package includes tailor-made adhesive solutions combined with full engineering and technical support. Service contracts are also available for added peace of mind.

For further details on our Solfre range or any of our adhesive application equipment then please get in touch - CLICK HERE

For further details about Future Rooms please visit: www.futurerooms.co.uk/

Or to find out more about installation, please visit: www.futuresips.co.uk/installation/

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

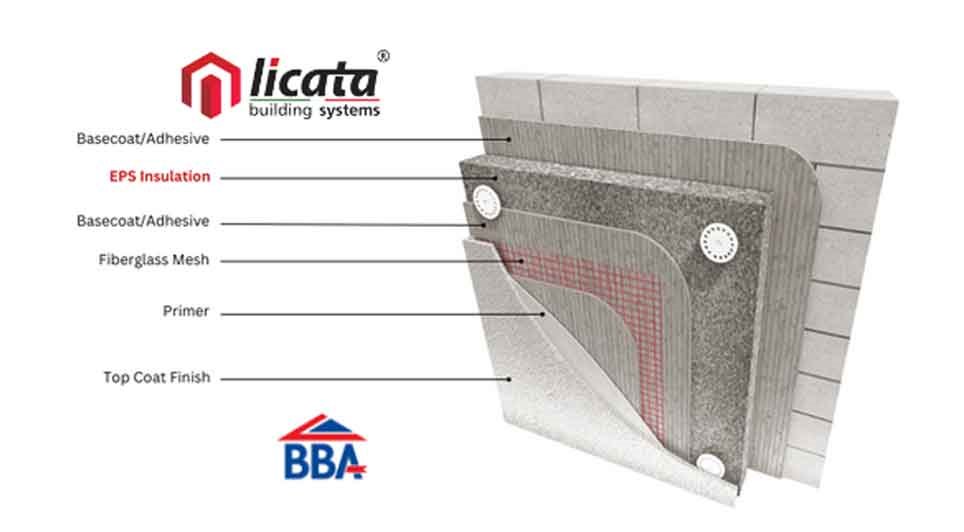

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London