Construction News

21/06/2021

BAM Commits To Plant-Based Fuel For All UK Construction Machinery

BAM has committed to running all of its UK construction machinery using recycled cooking oil, contributing to goals focused on reducing carbon emissions from its activities.

Hydrotreated Vegetable Oil (HVO) is an advanced renewable fuel derived from waste products. While the fuel currently costs around 15% more than red diesel, it reduces net CO2 emissions by as much as 90%.

In 2020, as part of its work delivering construction and infrastructure schemes across the UK, BAM consumed 7.1m litres of red diesel, around 70% of the company's total direct carbon footprint. HVO fuel will be provided through a new UK-wide contract with Crown Oil, helping to support BAM's broader strategy to make use of sustainable innovations to reduce the CO2 emissions related to its work.

Other measures include the phasing out of diesel generators and increasing use of alternative solutions such as photovoltaic cells to generate power at sites, the rollout of electric vehicles to all levels of the employee fleet, the increasing use of low-carbon materials, such as low cement concrete, in the design, construction and management of net-zero buildings.

Whilst HVO is considered an important stepping stone to a net zero carbon position, the ultimate goal is to eliminate all internal combustion engines and opt for electrically alternatives powered by batteries or hydrogen fuel cells. BAM is working closely with machinery manufacturers to accelerate the deployment of electric equipment that will help power its sites more cleanly and sustainably.

Sarah Jolliffe, Carbon Reduction Lead, BAM Nuttall said: "HVO fuel has been available for several years but it is only in the last 12-18 months that this fuel has been approved by plant and engine manufacturers for use in their equipment.

"HVO differs from gas oil, diesel and petrol as it isn't derived from crude oil, the main cause of greenhouse gases, including carbon dioxide. HVO is made through the hydrotreatment of pre-existing bio-waste products such as used cooking oil, waste plant and organic matter.

"Many of the projects we deliver and clients we support aim to decarbonise public transport or protect people from the effects of climate change. But the engineering solutions and construction operations have a high carbon impact. We want to reduce carbon throughout the whole lifecycle of a project, from the way the site operates through to the materials used in construction, and the way assets are operated, maintained and dismantled."

BAM's clients seeking to reduce the environmental impact of major engineering projects welcome the new scheme.

David Jarman, Programme Manager for Network Rail's South-East Multi-Disciplinary Framework, said: "We fully support sustainability initiatives on the Southern Multi-disciplinary Framework. The use of HVO fuel as an alternative to red diesel is a fantastic one which we hope will have a dramatic and positive effect on our carbon omissions. Trials that have been run on our stations portfolio have been positive and I am now excited to see it rolled out across all of our sites."

David Oake, Senior Advisor from the Environment Agency's Yorkshire Area, said: "On our Kirkstall Valley Farm site, part of Leeds Flood Alleviation Scheme Phase 2, 46% of our carbon emissions come from construction and a further 31% from the supply chain. Therefore, alternative fuels have a vital role to play in reducing our carbon emissions. We have committed to switch our plant on site to HVO, reducing our related net carbon emissions by 90%."

BAM is also collaborating with its supply chain partners to encourage further use of low carbon fuels and diesel alternatives to its supply chain.

BAM's chosen HVO supplier is Crown Oil. They only supply HVO which is certified to the International Sustainability & Carbon Certification (ISCC) and meets the UK Government's Renewable Transport Fuel Obligation (RFTO) standards.

Hydrotreated Vegetable Oil (HVO) is an advanced renewable fuel derived from waste products. While the fuel currently costs around 15% more than red diesel, it reduces net CO2 emissions by as much as 90%.

In 2020, as part of its work delivering construction and infrastructure schemes across the UK, BAM consumed 7.1m litres of red diesel, around 70% of the company's total direct carbon footprint. HVO fuel will be provided through a new UK-wide contract with Crown Oil, helping to support BAM's broader strategy to make use of sustainable innovations to reduce the CO2 emissions related to its work.

Other measures include the phasing out of diesel generators and increasing use of alternative solutions such as photovoltaic cells to generate power at sites, the rollout of electric vehicles to all levels of the employee fleet, the increasing use of low-carbon materials, such as low cement concrete, in the design, construction and management of net-zero buildings.

Whilst HVO is considered an important stepping stone to a net zero carbon position, the ultimate goal is to eliminate all internal combustion engines and opt for electrically alternatives powered by batteries or hydrogen fuel cells. BAM is working closely with machinery manufacturers to accelerate the deployment of electric equipment that will help power its sites more cleanly and sustainably.

Sarah Jolliffe, Carbon Reduction Lead, BAM Nuttall said: "HVO fuel has been available for several years but it is only in the last 12-18 months that this fuel has been approved by plant and engine manufacturers for use in their equipment.

"HVO differs from gas oil, diesel and petrol as it isn't derived from crude oil, the main cause of greenhouse gases, including carbon dioxide. HVO is made through the hydrotreatment of pre-existing bio-waste products such as used cooking oil, waste plant and organic matter.

"Many of the projects we deliver and clients we support aim to decarbonise public transport or protect people from the effects of climate change. But the engineering solutions and construction operations have a high carbon impact. We want to reduce carbon throughout the whole lifecycle of a project, from the way the site operates through to the materials used in construction, and the way assets are operated, maintained and dismantled."

BAM's clients seeking to reduce the environmental impact of major engineering projects welcome the new scheme.

David Jarman, Programme Manager for Network Rail's South-East Multi-Disciplinary Framework, said: "We fully support sustainability initiatives on the Southern Multi-disciplinary Framework. The use of HVO fuel as an alternative to red diesel is a fantastic one which we hope will have a dramatic and positive effect on our carbon omissions. Trials that have been run on our stations portfolio have been positive and I am now excited to see it rolled out across all of our sites."

David Oake, Senior Advisor from the Environment Agency's Yorkshire Area, said: "On our Kirkstall Valley Farm site, part of Leeds Flood Alleviation Scheme Phase 2, 46% of our carbon emissions come from construction and a further 31% from the supply chain. Therefore, alternative fuels have a vital role to play in reducing our carbon emissions. We have committed to switch our plant on site to HVO, reducing our related net carbon emissions by 90%."

BAM is also collaborating with its supply chain partners to encourage further use of low carbon fuels and diesel alternatives to its supply chain.

BAM's chosen HVO supplier is Crown Oil. They only supply HVO which is certified to the International Sustainability & Carbon Certification (ISCC) and meets the UK Government's Renewable Transport Fuel Obligation (RFTO) standards.

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

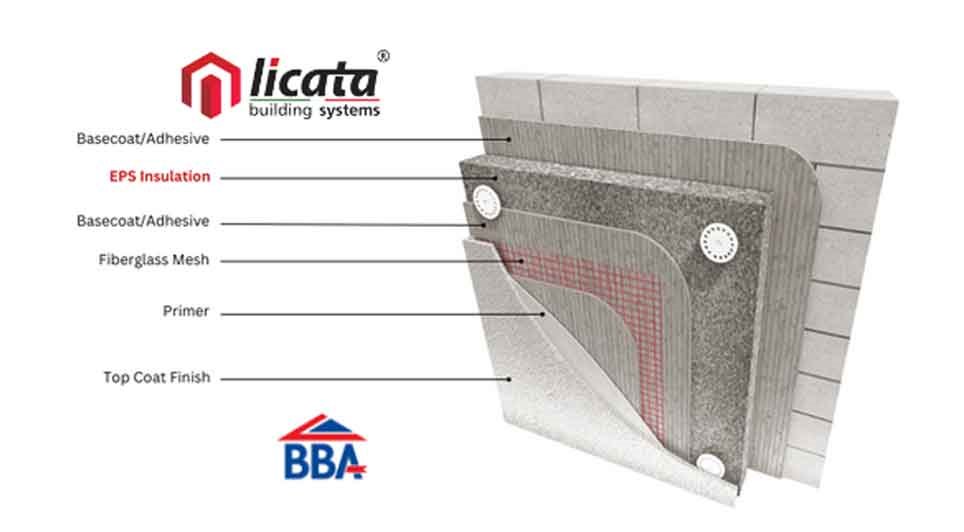

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London