The new generation of the Fronius MagicCleaner – the advanced electro-chemical cleaner for the perfect finish on stainless steel TIG welds and surfaces – is now available in two variants.

In addition to meeting the highest standards of aesthetics and hygiene, Fronius has packed even more into the robust shell: TIG welds can now be polished to a shine and workpieces can be marked with logos or serial numbers.

From interfering with a clean visual appearance in architecture, commercial kitchens or stainless steel swimming pools to the food and pharmaceutical industry, strong temper colours range from being a mere visual distraction to a quality defect to be avoided at all costs. They indicate a chromium oxide protective layer that is not intact and which can be a starting point for corrosion or deposits.

Cleaning and passivation restore this protective layer over the weld and on stainless steel surfaces. With the MagicCleaner, these can even be carried out at the same time in one simple and time-saving step. At just 4.5 kilograms, the lightweight MagicCleaner 150 (15 A output) is the perfect portable companion for construction sites. Its big brother, the MagicCleaner 300, is ideal for more intensive applications and for cleaning longer TIG welds. Delivering up to 30 A of performance, the MagicCleaner 300 weighs 14 kilograms and has a 1.8 l cleaning fluid tank as well as a patented compressed air blower. Both devices can be operated intuitively and supply the cleaning pad with electrolyte, thus eliminating the cumbersome process of having to immerse it in a separate container full of liquid.

Precise and economical consumption

With the MagicCleaner, the electrolyte is precisely dosed and conveyed specifically to where it is needed. The pads and brushes included in the scope of supply even penetrate into corners and gaps, ensuring optimum cleaning with minimal use of materials. Electro-chemical cleaning is also much more resource-friendly than conventional pickling in chemical baths and does not attack the material, as is the case with sandblasting, for example. Naturally Fronius also uses innovative inverter technology for its weld-cleaning solutions, which makes the devices lightweight and particularly energy-efficient.

Three functions in one device: cleaning, polishing and marking

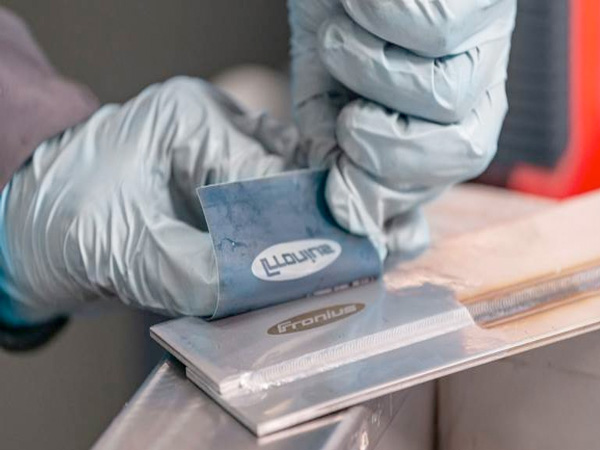

On highly polished materials, the weld seams should not only be pure, but downright radiant. Achieving this could not be easier thanks to the "electro-chemical polishing" function. Direct (DC) current is used to brighten the seams and make them shine in no time. But the MagicCleaner can do even more: company logos, item or serial numbers, and barcodes can be applied to stainless steel in black or white print. All that is needed is a suitably designed film and a special electrolyte solution. This is a good and cost-saving alternative to embossing, printing or gluing.

www.fronius.com

Construction News

24/02/2022

Clean Stainless Steel TIG Welds And Surfaces To Protection

17/04/2025

Willmott Dixon has been selected by Oldham Council to build a new Visitor Centre and Forestry Skills Centre at Northern Roots, the UK's largest urban farm and eco-park.

The development marks a major milestone in the transformation of 160 acres of green space at the heart of Oldham, part of the coun

17/04/2025

A groundbreaking ceremony has officially marked the commencement of construction for Versa, a state-of-the-art laboratory facility at King's Cross.

The project, which is being delivered by Morgan Sindall Construction, has been commissioned by Kadans Science Partner, a prominent European investor s

17/04/2025

A major milestone has been reached on Skanska's A428 improvement scheme, as the project team connected the new A428 and B1040 roads over a newly constructed bridge and opened it to traffic last weekend.

The achievement marks a crucial step forward in the project, enabling access to part of the main

17/04/2025

Our welfare unit hire division offers innovative ecowelfare units ready to be delivered nationwide and available in a range of configurations to accommodate 7, 12, or 15 persons with our most popular unit being our 12ft model fitted with advanced solar panels means there is no noise or vibrations f

17/04/2025

Huddersfield Station will temporarily close from Saturday 30 August to Monday 29 September 2025 to allow for a critical phase of engineering work as part of the Transpennine Route Upgrade (TRU).

The closure will enable extensive track and platform remodelling at the Grade I listed station, which ha

17/04/2025

Visitors to Mumbles over the Easter holidays can now enjoy the transformed promenade, as major upgrades under the Mumbles Coastal Protection Project near completion.

Contractors have begun laying a durable buff-coloured top surface, replacing the previously installed black Tarmac. The fresh finish

17/04/2025

Herefordshire Council has secured £1 million in funding from the government’s Public Sector Decarbonisation Scheme, to redevelop Hereford's Museum and Art Gallery into one of the most energy-efficient heritage public buildings in the UK.

The funding will be used to install a low carbon heating syst

17/04/2025

David Lloyd Leisure, Europe's leading health, fitness and wellness group, has submitted a planning application to Wirral Council for a new club at Wirral Waters.

The proposed club, set to create up to 100 permanent jobs upon completion, will be located at Peel Waters’ Bidston Dock site off Wallasey

16/04/2025

Pennyfarthing Homes has officially broken ground at Danes Park in New Milton, launching construction on a significant new residential development that will deliver 164 homes.

To mark the milestone, directors from Pennyfarthing Homes welcomed Councillor Steve Davies, Portfolio Holder for Housing and

16/04/2025

GMI Construction Group is celebrating the official opening of Dakota Newcastle, the North East's first Dakota Hotel, situated on Newcastle's Quayside.

The 118-room luxury boutique hotel, located at St Anne's Wharf, has welcomed its first guests and is poised to become a major addition to the region

UK

UK Ireland

Ireland Scotland

Scotland London

London