Fronius is adding to its range of smart, high-end TPS/i TWIN tandem welding systems. Synchronized welding with two individually controllable arcs has never been so easy as with the new TPS/i TWIN systems and the PMC TWIN and CMT TWIN welding processes. Both systems boast stable penetration and help save time thanks to their high speed and impressive deposition rate.

When it comes to high performance tandem welding, the main challenge is successfully controlling both arcs. Achieving this allows operators in the container, vehicle, and wagon construction industries to easily perform multi-layered or long welds in order to produce top-quality large-scale components. The TPS/i TWIN Push system, which is already well established on the market, is now joined by TWIN Push-Pull systems including the CMT TWIN process, which is well equipped to deal with such challenges. From now on, it will be possible to use tandem welding systems to join aluminum as well as steel.

• Two Versatile Powerhouses

The TPS/i TWIN Push-Pull solution is designed for use in motor vehicle and railway vehicle construction, and is used to weld aluminum profiles or pressure containers using the PMC (Pulse Multi Control) process. In addition to the PMC process, the new TPS/i CMT TWIN system also uses the CMT (Cold Metal Transfer) process, thereby also enabling welding of aluminum, nickel-base alloys, and high-strength steels. The controlled heat input provided by the Cold Metal Transfer process is also particularly well suited for thin sheet applications. Penetration and weld profile can be further optimized if each TWIN arc is set to a different performance level.

• High Speed and 25kg Deposition Rate

In practice, the benefits of tandem welding compared to single wire welding are particularly apparent in cases where a perfect result needs to be produced at high speed. With a deposition rate of up to 25 kilograms per hour and a speed of up to 4 meters per minute, the Fronius TPS/i TWIN systems are quite the workhorses. This is made possible thanks to a wire speed performance of around 30 meters per minute for each processing line. Despite this speed, a flawless finish is achieved with reliable penetration quality and no weld-seam porosity. This reduces both the number of layers and the production time.

• Exceptional Weld Quality – Achievable at Any Time

The integrated self-regulating TWIN process ensures optimal results and high efficiency, with only the essential settings needing to be adjusted. In the background, the system independently controls the welding parameters and variables to ensure the arcs are always precise. In order to ensure completely stable welding, a high level of process reliability is required, and this is guaranteed by the combination of PMC and CMT. Innovative solutions for optimal wire feeding such as the TWIN Drive or the wire buffer component ensure a steady supply of wire, thereby increasing the reliability of the welding process and taking process stability to another level. This cuts reworking and production errors to a minimum, thus saving time and resources.

• Rapid and Precise Thanks to Smart Assistance Systems

The Fronius TWIN series offers a range of different functions and robot assistance systems that help welders to automate the production process as efficiently as possible. For example, SFI (spatter-free ignition) prevents spatter during ignition and the innovative chipping hammer removes previously formed slag by way of reversing the wire movement to ensure a clean start to the weld. SeamTracking automatically compensates for deviations, and TouchSense equips the robot with a positioning sensor that it can then use to compensate for clamping and component tolerances. WireSense measures these tolerances and transmits them directly to the robot. All this reduces welding errors, reworking time, and even discards, which directly contributes to increasing efficiency in high performance welding.

For further information, please visit our website.

Construction News

05/05/2022

New Additions To Fronius TPS/i Twin Tandem Welding Series

12/06/2025

Work is due to begin this summer on a new £27.3 million leisure centre in Bishop Auckland, marking the start of Durham County Council’s flagship development under its Leisure Transformation Programme.

The new facility will replace the aging Woodhouse Leisure Complex, the oldest in the council's por

12/06/2025

Esh Construction has been awarded a £23 million contract by Thirteen Group to build 96 new affordable homes in Sunderland.

Located in the Hendon area, the development will include 75 two-, three-, and four-bedroom houses and 21 two-bedroom bungalows. All homes will be available for affordable rent.

12/06/2025

Willmott Dixon has been appointed by Queen Mary University of London to lead a £48.8 million redevelopment of its School of Business and Management in Tower Hamlets.

The project will see the construction of a new 6,700m², seven-storey building that will replace the current outdated facility. Schedu

12/06/2025

VolkerRail has been awarded the Tranche 6 contract to renew signalling structures across the North West of England, as part of Network Rail's ongoing efforts to modernise ageing railway infrastructure in the region.

This latest contract, valued at £19.9 million, builds on the success of the previou

12/06/2025

Hometrack has been awarded a major contract by Homes England to deliver comprehensive housing market intelligence that will underpin the government's regeneration and housing delivery efforts over the next four years.

The UK-based property analytics firm will supply detailed data and insights to th

12/06/2025

A group of subcontractors working on a Citi project in London have come together to fund a new minibus for a Streatham-based charity that supports children and young people.

Overbury, along with members of its Citi project supply chain, have collectively financed a Variety Sunshine Coach for the St

12/06/2025

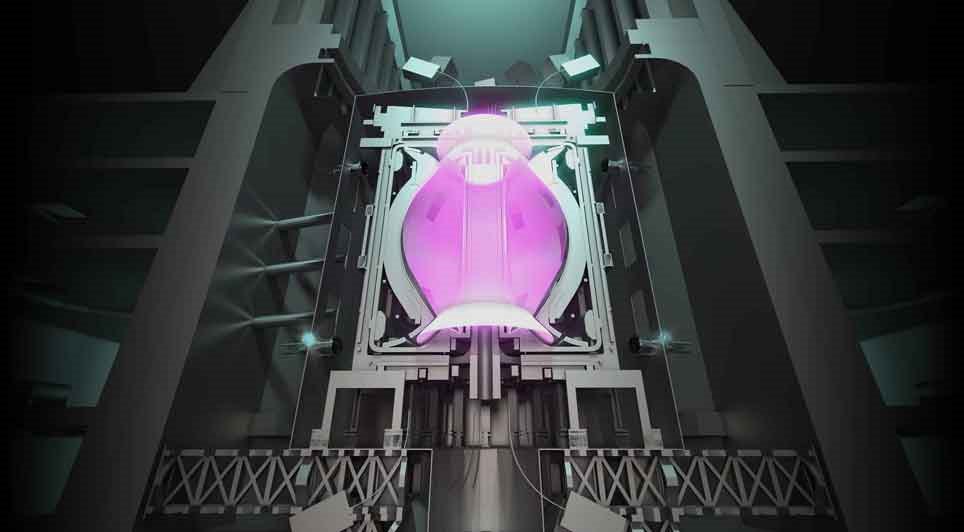

A record-breaking £2.5 billion of additional funding has been announced this week by Chancellor of the Exchequer, Rt Hon Rachel Reeves, to accelerate the development of the world’s first prototype fusion power plant in the UK.

Known as Spherical Tokamak for Energy Production (STEP), the pioneering

12/06/2025

As the UK water industry ramps up infrastructure investment, forecasting a 48% expansion in the engineering construction workforce within water treatment by 2030, Essential Site Skills is proud to promote the newly launched EUSR "Products for Drinking Water" scheme.

This course is designed to hel

12/06/2025

Leeds City Council has launched a public consultation on new planning guidance that could pave the way for the large-scale regeneration of land surrounding Elland Road football stadium, potentially delivering a multi-billion-pound boost to the city’s economy.

The draft 'Elland Road 2025 Informal Pl

12/06/2025

Network Rail (Wales and Borders) is carrying out essential track renewal and maintenance works between Bridgend and St Fagans as part of efforts to ensure the long-term safety and reliability of the rail network.

The upgrade programme will involve replacing rails, sleepers, and the ballast (stones)

UK

UK Ireland

Ireland Scotland

Scotland London

London