Construction News

10/06/2022

Construction Work Starts On HS2's First 'Green Tunnel'

Construction work has started at the site of HS2's first innovative 'green tunnel', designed to blend the high speed railway into the landscape and reduce disruption for communities.

Unlike a normal underground tunnel, the one-and-a-half mile (2.5km) Chipping Warden green tunnel in Northamptonshire is being built on the surface using a pioneering off-site manufacturing approach to speed up construction and improve efficiency.

This approach will see more than five thousand giant concrete tunnel segments made in a factory in Derbyshire before being assembled on site. The completed tunnel will then be covered by earth, with trees, shrubs and hedgerows planted to fit in with the surrounding countryside.

Chipping Warden is one of five 'green tunnels' that are being built on phase one of the HS2 project, which is designed to improve links between London, Birmingham and the north, help level-up the economy and provide a low carbon alternative to car and air travel.

Applying lessons from the construction of the latest French high speed lines, the off-site approach was developed by HS2’s main works contractor, EKFB - a team made up of Eiffage, Kier, Ferrovial Construction and BAM Nuttall. The tunnel segments are being made by Stanton Precast in Ilkeston Derbyshire as part of a contract which is set to create up to 100 local jobs.

HS2 Ltd's Project Client Rohan Perin, said: "The Chipping Warden green tunnel is a great example of what we're doing to reduce disruption for people living close to the railway - and it’s fantastic to see the first arches in position.

"Our trains will be powered by zero carbon electricity but it’s also important to reduce the amount of carbon embedded in construction. The off-site manufacturing techniques being used will help cutting the overall amount of carbon-intensive concrete and steel in the tunnel and make the whole process faster, more efficient and therefore less disruptive for the community."

Designed as an m-shaped double arch, the tunnel will have separate halves for southbound and northbound trains – each one the height of two double-decker buses. Instead of casting the whole tunnel on site, five different concrete precast segments will be slotted together to achieve the double arch - one central pier, two side walls and two roof slabs. All 5,020 segments will be steel reinforced, with the largest weighing up to 43 tonnes.

Concrete and steel are some of the biggest sources of carbon emissions within the construction industry and by reducing the amount of both materials needed for the tunnel, this lighter-weight modular approach is expected to more than halve the amount of carbon embedded in the structure. It also requires less people and equipment on site, improving safety and reducing disruption for residents.

Unlike a normal underground tunnel, the one-and-a-half mile (2.5km) Chipping Warden green tunnel in Northamptonshire is being built on the surface using a pioneering off-site manufacturing approach to speed up construction and improve efficiency.

This approach will see more than five thousand giant concrete tunnel segments made in a factory in Derbyshire before being assembled on site. The completed tunnel will then be covered by earth, with trees, shrubs and hedgerows planted to fit in with the surrounding countryside.

Chipping Warden is one of five 'green tunnels' that are being built on phase one of the HS2 project, which is designed to improve links between London, Birmingham and the north, help level-up the economy and provide a low carbon alternative to car and air travel.

Applying lessons from the construction of the latest French high speed lines, the off-site approach was developed by HS2’s main works contractor, EKFB - a team made up of Eiffage, Kier, Ferrovial Construction and BAM Nuttall. The tunnel segments are being made by Stanton Precast in Ilkeston Derbyshire as part of a contract which is set to create up to 100 local jobs.

HS2 Ltd's Project Client Rohan Perin, said: "The Chipping Warden green tunnel is a great example of what we're doing to reduce disruption for people living close to the railway - and it’s fantastic to see the first arches in position.

"Our trains will be powered by zero carbon electricity but it’s also important to reduce the amount of carbon embedded in construction. The off-site manufacturing techniques being used will help cutting the overall amount of carbon-intensive concrete and steel in the tunnel and make the whole process faster, more efficient and therefore less disruptive for the community."

Designed as an m-shaped double arch, the tunnel will have separate halves for southbound and northbound trains – each one the height of two double-decker buses. Instead of casting the whole tunnel on site, five different concrete precast segments will be slotted together to achieve the double arch - one central pier, two side walls and two roof slabs. All 5,020 segments will be steel reinforced, with the largest weighing up to 43 tonnes.

Concrete and steel are some of the biggest sources of carbon emissions within the construction industry and by reducing the amount of both materials needed for the tunnel, this lighter-weight modular approach is expected to more than halve the amount of carbon embedded in the structure. It also requires less people and equipment on site, improving safety and reducing disruption for residents.

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

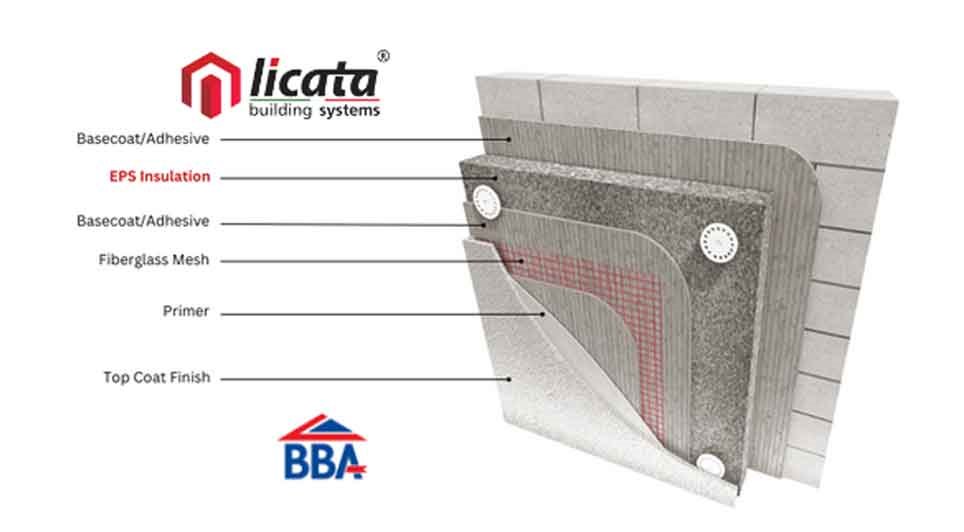

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London