Construction News

25/07/2023

Groundforce Shorco Supply Excavation For Thame Tideway Tunnel

Groundforce Shorco has provided specialist Air Treatment Unit (ATU) excavation for the Thames Tideway Tunnel, as part of the ongoing Super Sewer project in London.

The project requires a number of ATUs to be installed along the route of the 25km tunnel, to treat exhausted air from the super-sewer.

Last year, Groundforce provided Costain, Vinci Construction Grands Projects and Bachy Soletanche Joint Venture on the Eastern section with sheet piles and a range of medium and heavy-duty bracing frames for the ATU excavation in the Deptford Church Street site.

Now, Groundforce Shorco is supporting another Tideway ATU excavation, this time at their Greenwich Pumping Station site.

This ATU excavation is especially challenging as it is in a very confined location, bounded on one side by Greenwich Pumping Station, a listed building, and on an adjacent side by an acoustic enclosure used by the JV to receive precast concrete tunnel sections for the Greenwich connection tunnel.

Civils Senior Engineer, Andrew Bellamy, said: "Although the ATU is only about 8m x 8m in plan, a sheet piled structure of 13m x 15m was designed to enable adjacent ventilation pipework and ducting to be installed simultaneously.

"Stringent limits on the deflection of the sheet were set due to the proximity of the excavation to the acoustic enclosure foundations, which includes a gantry crane, working continuously to supply the secondary lining works. The excavation was sheet piled on three sides, the fourth being the Grade 2 listed Thames Water pumping station."

Access to the acoustic enclosure needed to be maintained throughout the works, adding further restrictions to the already confined working area. The solution was to create a chamfer to one corner of the 14m x 13m x 5m deep excavation. This chamfer allowed articulated lorries to continue delivering materials.

Bellamy continued: "Due to the orientation of the site access gate it was physically impossible to move the vehicle route away from the ATU and without the chamfered corner vehicle access would have been completely impossible for HGVs."

Groundforce Shorco Area Manager Arpad Nagy added: "There are two excavators on site, including one 45-tonner, and three lorry deliveries per shift bringing tunnel segments for the tunnel boring machine which meant that our design had to accommodate an increased surcharge of 15kN/m2."

The excavation is lined with 6m-long GU13N steel sheet piles and braced with three levels of Groundforce's hydraulic Mega Brace frames. Four MP150 modular hydraulic props were installed as knee-braces (ie spanning the corners of the excavation) at all three levels within the excavation – a total of 12 props.

The MP150s are attached to brackets welded to the waling beams.

"These act as shear-stoppers to prevent the props sliding along the beams," explained Arpad.

One side of the excavation runs along the top of the pumping station's 10m-deep foundations.

"The JV had to drill into the foundation of the Grade 2 listed Thames Water pumping station in order to facilitate the installation of gallows brackets required to support the temporary frames," explains Arpad.

The support structure is designed to limit deflections in the sheet piles to within 10mm.

Designing the support system was complicated by the need to chamfer the corner of the excavation, says Arpad: "Once you lose that corner you need to recalculate the loadings and reposition the knee braces."

With the bracing installed, the 800mm-thick base slab was cast. When this had reached full strength, the two bottom levels of bracing could be removed to allow formwork to be assembled for the concrete wall lining.

The top level of bracing is due to be removed when the lining walls have reached 1m below ground level.

Despite the complexity of the job, design and installation of the support system has gone very smoothly.

"Groundforce have served us well on the ATU package, engaging at the design stage, attending site to deliver toolbox talks on the EMV, and generally with how the works were progressing," concluded Mr Bellamy.

The project requires a number of ATUs to be installed along the route of the 25km tunnel, to treat exhausted air from the super-sewer.

Last year, Groundforce provided Costain, Vinci Construction Grands Projects and Bachy Soletanche Joint Venture on the Eastern section with sheet piles and a range of medium and heavy-duty bracing frames for the ATU excavation in the Deptford Church Street site.

Now, Groundforce Shorco is supporting another Tideway ATU excavation, this time at their Greenwich Pumping Station site.

This ATU excavation is especially challenging as it is in a very confined location, bounded on one side by Greenwich Pumping Station, a listed building, and on an adjacent side by an acoustic enclosure used by the JV to receive precast concrete tunnel sections for the Greenwich connection tunnel.

Civils Senior Engineer, Andrew Bellamy, said: "Although the ATU is only about 8m x 8m in plan, a sheet piled structure of 13m x 15m was designed to enable adjacent ventilation pipework and ducting to be installed simultaneously.

"Stringent limits on the deflection of the sheet were set due to the proximity of the excavation to the acoustic enclosure foundations, which includes a gantry crane, working continuously to supply the secondary lining works. The excavation was sheet piled on three sides, the fourth being the Grade 2 listed Thames Water pumping station."

Access to the acoustic enclosure needed to be maintained throughout the works, adding further restrictions to the already confined working area. The solution was to create a chamfer to one corner of the 14m x 13m x 5m deep excavation. This chamfer allowed articulated lorries to continue delivering materials.

Bellamy continued: "Due to the orientation of the site access gate it was physically impossible to move the vehicle route away from the ATU and without the chamfered corner vehicle access would have been completely impossible for HGVs."

Groundforce Shorco Area Manager Arpad Nagy added: "There are two excavators on site, including one 45-tonner, and three lorry deliveries per shift bringing tunnel segments for the tunnel boring machine which meant that our design had to accommodate an increased surcharge of 15kN/m2."

The excavation is lined with 6m-long GU13N steel sheet piles and braced with three levels of Groundforce's hydraulic Mega Brace frames. Four MP150 modular hydraulic props were installed as knee-braces (ie spanning the corners of the excavation) at all three levels within the excavation – a total of 12 props.

The MP150s are attached to brackets welded to the waling beams.

"These act as shear-stoppers to prevent the props sliding along the beams," explained Arpad.

One side of the excavation runs along the top of the pumping station's 10m-deep foundations.

"The JV had to drill into the foundation of the Grade 2 listed Thames Water pumping station in order to facilitate the installation of gallows brackets required to support the temporary frames," explains Arpad.

The support structure is designed to limit deflections in the sheet piles to within 10mm.

Designing the support system was complicated by the need to chamfer the corner of the excavation, says Arpad: "Once you lose that corner you need to recalculate the loadings and reposition the knee braces."

With the bracing installed, the 800mm-thick base slab was cast. When this had reached full strength, the two bottom levels of bracing could be removed to allow formwork to be assembled for the concrete wall lining.

The top level of bracing is due to be removed when the lining walls have reached 1m below ground level.

Despite the complexity of the job, design and installation of the support system has gone very smoothly.

"Groundforce have served us well on the ATU package, engaging at the design stage, attending site to deliver toolbox talks on the EMV, and generally with how the works were progressing," concluded Mr Bellamy.

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

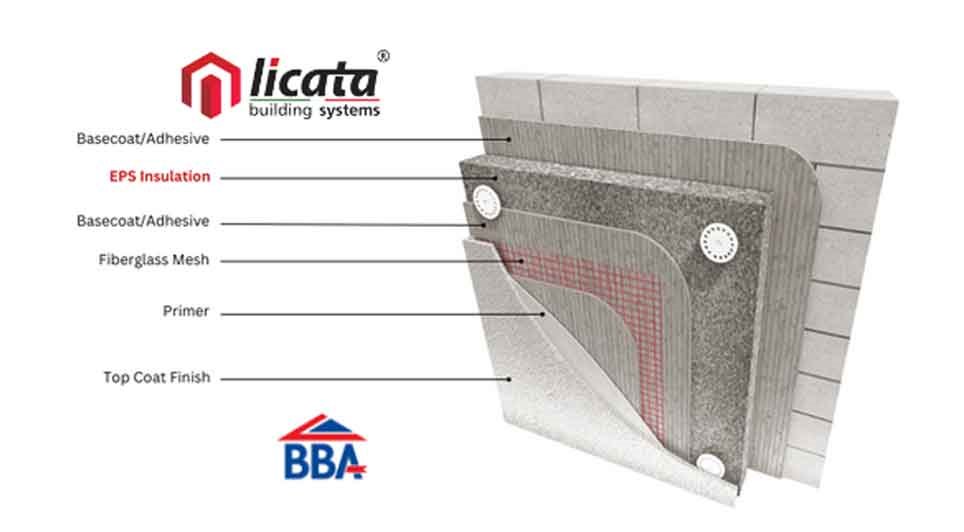

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London