Construction News

13/09/2023

Yanmar's Green Challenge 2050

This year summer's extreme weather has left few in doubt that the environment is under pressure. Helping turn the tide on climate change is everyone's responsibility – including companies. Yanmar Compact Equipment is happy to play its part – and recently signed up to the Yanmar Green Challenge, a Yanmar Group initiative.

With the northern hemisphere experiencing a summer of searing temperatures, extreme weather and rampant fires in 2023, the long-predicted consequences of a warming planet were plain to see. But averting a climate emergency is still within our reach, and governments, individuals and companies can make a difference.

Yanmar Compact Equipment is committed to adopting more sustainable practices – and to helping its customers and users of its products to do the same. The company, part of the Yanmar Group, is committed to creating a sustainable future and, along with its fellow Group companies, recently launched the Yanmar Green Challenge 2050 to help achieve this aim.

The challenge commits the entire company to be free from greenhouse gas emissions by 2050. To achieve that, action needs to happen today. These actions can be divided into three areas – to reduce the greenhouse gasses the company makes in its own operations, to maximise the reuse of resources– and to help its customers also achieve these same objectives.

Commenting on the commitment, Yanmar CE's CEO Giuliano Parodi said: "The Yanmar Green Challenge 2050 starts with us. If we all play our part and show our commitment, then we will be in a position to convince our customers and business partners to follow our lead and reduce their greenhouse gas emissions too. It is important that we take the lead and show what is possible."

The Green Challenge is pulling together individual initiatives that were already ongoing into a cohesive 'big idea'. To make Yanmar CE's manufacturing cleaner, the company is reducing its energy use – through more effective insulation of its buildings and fitting extensive solar panels on the roofs of factories. Sourcing green energy and increasing energy independence will lower Yanmar's carbon footprint – and also reduce overheads. This process will take time to complete, but the direction of travel is clear.

Progress will be redoubled when it comes to product innovation. The process of making engines even more fuel efficient continues, and Yanmar has recently unveiled an all-electric range of compact excavator, compact wheel loader and compact tracked carrier. New tech is also being considered – particularly the potential of hydrogen to power the company's machines. The electrification of machines brings tangible benefits for the climate – but for customers too. They are quieter, cleaner and require less maintenance – boosting uptime and productivity.

The materials Yanmar makes its products from is also under constant scrutiny. Today, machines are made from steel, plastics, rubber etc – and these aren't easily substituted for greener materials. But as cleaner alternatives appear they will be embraced, and Yanmar is working hard to find smarter ways to 'reduce, reuse and recycle' materials and components.

Doing good for the climate will also have associated business benefits. The Green Challenge will help strengthen the Yanmar brand compared to its competitors, help it become more attractive to investors and attract and retain talent.

This summer's extreme weather conditions are likely to become commonplace if insufficient action is taken to avert climate change. Environmental legislation will undoubtedly increase, and those companies already advanced in making the circular economy will benefit.

"Meeting the Green Challenge 2050 is not just about our products – it's also about our mindset," concludes Yanmar CE CEO Giuliano Parodi. "Doing nothing is not an option, so let's all start today by looking for ways to be more sustainable in our everyday lives."

With the northern hemisphere experiencing a summer of searing temperatures, extreme weather and rampant fires in 2023, the long-predicted consequences of a warming planet were plain to see. But averting a climate emergency is still within our reach, and governments, individuals and companies can make a difference.

Yanmar Compact Equipment is committed to adopting more sustainable practices – and to helping its customers and users of its products to do the same. The company, part of the Yanmar Group, is committed to creating a sustainable future and, along with its fellow Group companies, recently launched the Yanmar Green Challenge 2050 to help achieve this aim.

The challenge commits the entire company to be free from greenhouse gas emissions by 2050. To achieve that, action needs to happen today. These actions can be divided into three areas – to reduce the greenhouse gasses the company makes in its own operations, to maximise the reuse of resources– and to help its customers also achieve these same objectives.

Commenting on the commitment, Yanmar CE's CEO Giuliano Parodi said: "The Yanmar Green Challenge 2050 starts with us. If we all play our part and show our commitment, then we will be in a position to convince our customers and business partners to follow our lead and reduce their greenhouse gas emissions too. It is important that we take the lead and show what is possible."

The Green Challenge is pulling together individual initiatives that were already ongoing into a cohesive 'big idea'. To make Yanmar CE's manufacturing cleaner, the company is reducing its energy use – through more effective insulation of its buildings and fitting extensive solar panels on the roofs of factories. Sourcing green energy and increasing energy independence will lower Yanmar's carbon footprint – and also reduce overheads. This process will take time to complete, but the direction of travel is clear.

Progress will be redoubled when it comes to product innovation. The process of making engines even more fuel efficient continues, and Yanmar has recently unveiled an all-electric range of compact excavator, compact wheel loader and compact tracked carrier. New tech is also being considered – particularly the potential of hydrogen to power the company's machines. The electrification of machines brings tangible benefits for the climate – but for customers too. They are quieter, cleaner and require less maintenance – boosting uptime and productivity.

The materials Yanmar makes its products from is also under constant scrutiny. Today, machines are made from steel, plastics, rubber etc – and these aren't easily substituted for greener materials. But as cleaner alternatives appear they will be embraced, and Yanmar is working hard to find smarter ways to 'reduce, reuse and recycle' materials and components.

Doing good for the climate will also have associated business benefits. The Green Challenge will help strengthen the Yanmar brand compared to its competitors, help it become more attractive to investors and attract and retain talent.

This summer's extreme weather conditions are likely to become commonplace if insufficient action is taken to avert climate change. Environmental legislation will undoubtedly increase, and those companies already advanced in making the circular economy will benefit.

"Meeting the Green Challenge 2050 is not just about our products – it's also about our mindset," concludes Yanmar CE CEO Giuliano Parodi. "Doing nothing is not an option, so let's all start today by looking for ways to be more sustainable in our everyday lives."

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

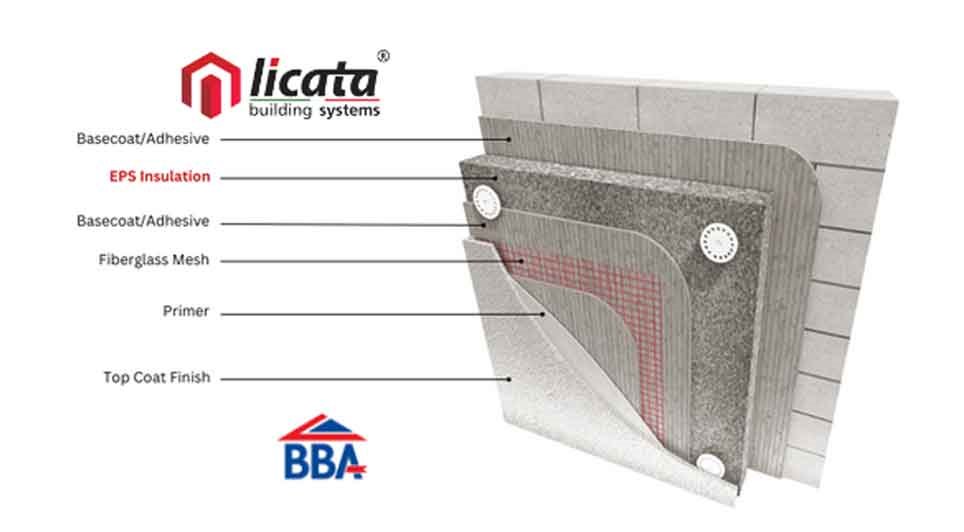

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London