Construction News

17/05/2024

ParaProducts' Alkaline Resilience

Unveiling the Long-Term Durability of ParaProducts in Alkaline Soils.

In the realm of civil engineering and geotechnical solutions, understanding and mitigating the impacts of soil conditions are crucial for the sustainability and success of any project. Highly alkaline soils, with pH levels exceeding 9, represent one such challenge, known for accelerating the degradation of materials. These conditions can arise from both natural causes, such as the presence of certain minerals or geological formations, and human activity, often occurring in projects where materials such as lime or cement are added to the soil to improve its mechanical properties, inadvertently raising the soil’s pH and creating a more corrosive environment for geosynthetic products.

A Groundbreaking Testing Initiative

In this challenging landscape, the ParaProduct High Alkalinity Testing Initiative by Maccaferri emerges as a pioneering venture. Aimed at rigorously assessing the durability and efficacy of its ParaProducts under highly alkaline conditions, the initiative has brought to light the resilience and reliability of these geogrid solutions.

Insightful Campaign: Evaluating ParaProducts’ Two-Decade Performance in Alkaline Soil Conditions

Spanning over three years, the initiative focused on evaluating ParaProducts that had been deployed in the field for up to two decades. Concentrated in the UK and Italy, these projects provided a real-world backdrop to assess the geogrids’ performance in alkaline conditions, where soil pH was initially set at a formidable 12. The campaign entailed the careful exhumation of materials from several job sites, with subsequent analysis conducted by accredited laboratories. The British Board of Agrément (BBA) supervised these tests, ensuring rigorous evaluation standards.

Revealing Remarkable Results

The campaign’s findings were striking. Despite the high alkalinity, which could potentially compromise material integrity, the tested ParaProducts exhibited outstanding durability. The residual tensile strength of these materials impressively exceeded 95% of their certified characteristic value. For instance, in both the Moodiesburn project in Glasgow and the Tangenziale di Forlì in Italy, the geogrids not only met but significantly surpassed the demanding requirements set for geosynthetic materials.

Such results are particularly illuminating, given the high pH conditions encountered at these sites due to the use of lime and cement for soil stabilization. These outcomes underscore the efficacy of ParaProducts in maintaining structural integrity and performance, even in environments that have undergone chemical alterations to enhance soil mechanics.

Forward-Looking Commitment

The ParaProduct High Alkalinity Testing Initiative underscores Maccaferri’s unwavering dedication to innovation and quality. As shared Giulia Lugli during a specialised webinar, this initiative provides a roadmap for future projects, illustrating the adaptability and resilience of Maccaferri’s solutions in the face of geotechnical challenges.

With a legacy of pioneering engineering solutions, Maccaferri remains committed to pushing the boundaries of geosynthetic performance. The geotechnical community eagerly awaits further advancements from Maccaferri, promising to redefine durability and reliability standards in the industry.

www.maccaferri.com/uk/

In the realm of civil engineering and geotechnical solutions, understanding and mitigating the impacts of soil conditions are crucial for the sustainability and success of any project. Highly alkaline soils, with pH levels exceeding 9, represent one such challenge, known for accelerating the degradation of materials. These conditions can arise from both natural causes, such as the presence of certain minerals or geological formations, and human activity, often occurring in projects where materials such as lime or cement are added to the soil to improve its mechanical properties, inadvertently raising the soil’s pH and creating a more corrosive environment for geosynthetic products.

A Groundbreaking Testing Initiative

In this challenging landscape, the ParaProduct High Alkalinity Testing Initiative by Maccaferri emerges as a pioneering venture. Aimed at rigorously assessing the durability and efficacy of its ParaProducts under highly alkaline conditions, the initiative has brought to light the resilience and reliability of these geogrid solutions.

Insightful Campaign: Evaluating ParaProducts’ Two-Decade Performance in Alkaline Soil Conditions

Spanning over three years, the initiative focused on evaluating ParaProducts that had been deployed in the field for up to two decades. Concentrated in the UK and Italy, these projects provided a real-world backdrop to assess the geogrids’ performance in alkaline conditions, where soil pH was initially set at a formidable 12. The campaign entailed the careful exhumation of materials from several job sites, with subsequent analysis conducted by accredited laboratories. The British Board of Agrément (BBA) supervised these tests, ensuring rigorous evaluation standards.

Revealing Remarkable Results

The campaign’s findings were striking. Despite the high alkalinity, which could potentially compromise material integrity, the tested ParaProducts exhibited outstanding durability. The residual tensile strength of these materials impressively exceeded 95% of their certified characteristic value. For instance, in both the Moodiesburn project in Glasgow and the Tangenziale di Forlì in Italy, the geogrids not only met but significantly surpassed the demanding requirements set for geosynthetic materials.

Such results are particularly illuminating, given the high pH conditions encountered at these sites due to the use of lime and cement for soil stabilization. These outcomes underscore the efficacy of ParaProducts in maintaining structural integrity and performance, even in environments that have undergone chemical alterations to enhance soil mechanics.

Forward-Looking Commitment

The ParaProduct High Alkalinity Testing Initiative underscores Maccaferri’s unwavering dedication to innovation and quality. As shared Giulia Lugli during a specialised webinar, this initiative provides a roadmap for future projects, illustrating the adaptability and resilience of Maccaferri’s solutions in the face of geotechnical challenges.

With a legacy of pioneering engineering solutions, Maccaferri remains committed to pushing the boundaries of geosynthetic performance. The geotechnical community eagerly awaits further advancements from Maccaferri, promising to redefine durability and reliability standards in the industry.

www.maccaferri.com/uk/

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

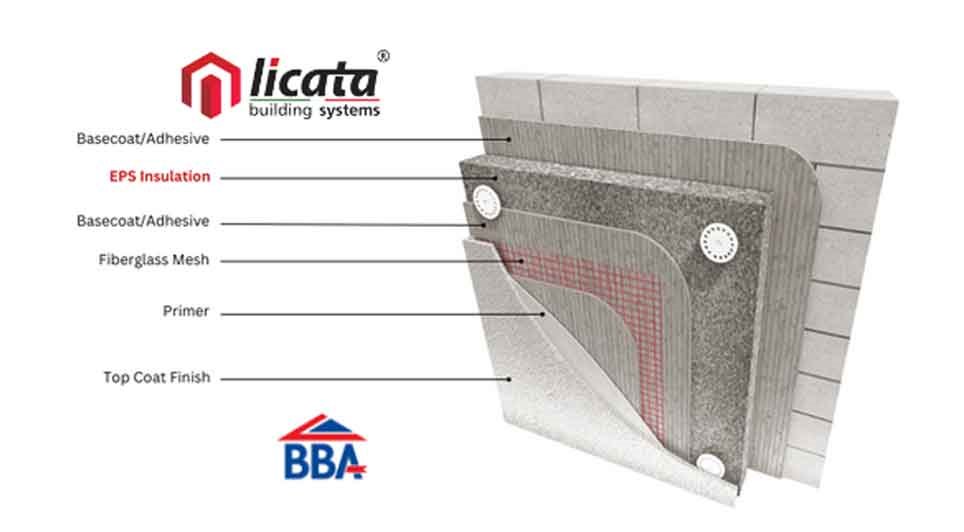

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London