Construction News

26/02/2009

New State-Of-The-Art Facilities For Lincoln Minster School Relies On A Contiguous Piled Wall Solution

Project Overview

The concept for the new facilities was based on excavating the site to provide the extra room required for the development. This required a contiguous pile retaining wall to support the surrounding ground and neighbouring roads. Van Elle, one of the UK's leading piling and ground engineering specialists were contracted to carry out all the piling works on this technically challenging site, as their expertise had been proven on similar projects.

The piling works, awarded by main contractor Quibell, worth over £400k involved a total of 298 No. Duplex and CFA piles.

In addition to the piling works, Van Elle's geotechnical team carried out a series of boreholes - as only limited information was available during the early tender stages. This gave a better picture of the actual ground conditions enabling Van Elle's engineers to make an informed choice of piling method.

The issues and the solutions

Not only is the school on a steep hillside surrounded by historic buildings, there is also a convent within 4m of the piling site and an adjacent main road. Lincoln itself sits on a rocky outcrop of Lincolnshire limestone with made ground above, making the ground conditions as challenging to work with as the site itself.

Because of these issues the use of Duplex piles was the only economical and practical solution. The Duplex piling method allowed the piles to be temporary cased through the made ground and socketed a minimum of 5m below dredge level into the bedrock.

The site was live during term time and as well as restricted access to and on site, deliveries could not be accepted before 9.30am and after 3.30pm to ensure the safety of the students and parents. This meant rig choice and logistics were crucial. Rigs were selected based on their size, weight and manoeuvrability as well as their suitability for the job. Well planned logistics and pre-ordered deliveries meant that there were no delays waiting for materials to arrive.

Construction

188 No. Duplex piles were drilled to form the contiguous wall, 660mm diameter temporary casing was drilled 5m onto the rock then the rock was drilled out using rotary percussive and Down The Hole Hammer techniques. The bore was then tremied with concrete, reinforcement was installed and the temporary casing removed.

The site investigation showed potential shallow mine workings at 1-2m deep along the south and east sides of the site. Van Elle solved this problem by pumping in a weak concrete grout, allowing it to set then re-boring through the concrete to form the Duplex piles.

The contract was complete within the anticipated programme and budget, even with the several unexpected challenges which arose during construction.

The retaining wall has now been excavated out by main contractor Quibell, and the steel frame is also being erected. The project is due for completion in 2010 when the students will be able to enjoy their new facilities.

The concept for the new facilities was based on excavating the site to provide the extra room required for the development. This required a contiguous pile retaining wall to support the surrounding ground and neighbouring roads. Van Elle, one of the UK's leading piling and ground engineering specialists were contracted to carry out all the piling works on this technically challenging site, as their expertise had been proven on similar projects.

The piling works, awarded by main contractor Quibell, worth over £400k involved a total of 298 No. Duplex and CFA piles.

In addition to the piling works, Van Elle's geotechnical team carried out a series of boreholes - as only limited information was available during the early tender stages. This gave a better picture of the actual ground conditions enabling Van Elle's engineers to make an informed choice of piling method.

The issues and the solutions

Not only is the school on a steep hillside surrounded by historic buildings, there is also a convent within 4m of the piling site and an adjacent main road. Lincoln itself sits on a rocky outcrop of Lincolnshire limestone with made ground above, making the ground conditions as challenging to work with as the site itself.

Because of these issues the use of Duplex piles was the only economical and practical solution. The Duplex piling method allowed the piles to be temporary cased through the made ground and socketed a minimum of 5m below dredge level into the bedrock.

The site was live during term time and as well as restricted access to and on site, deliveries could not be accepted before 9.30am and after 3.30pm to ensure the safety of the students and parents. This meant rig choice and logistics were crucial. Rigs were selected based on their size, weight and manoeuvrability as well as their suitability for the job. Well planned logistics and pre-ordered deliveries meant that there were no delays waiting for materials to arrive.

Construction

188 No. Duplex piles were drilled to form the contiguous wall, 660mm diameter temporary casing was drilled 5m onto the rock then the rock was drilled out using rotary percussive and Down The Hole Hammer techniques. The bore was then tremied with concrete, reinforcement was installed and the temporary casing removed.

The site investigation showed potential shallow mine workings at 1-2m deep along the south and east sides of the site. Van Elle solved this problem by pumping in a weak concrete grout, allowing it to set then re-boring through the concrete to form the Duplex piles.

The contract was complete within the anticipated programme and budget, even with the several unexpected challenges which arose during construction.

The retaining wall has now been excavated out by main contractor Quibell, and the steel frame is also being erected. The project is due for completion in 2010 when the students will be able to enjoy their new facilities.

29/01/2025

Caddick Construction has been awarded a £43 million contract to deliver the first phase of Cole Waterhouse's flagship regeneration scheme in Digbeth, Birmingham.

The project, known as Upper Trinity Street, marks a significant step in the area’s transformation.

Spanning 182,986 square feet, the re

29/01/2025

McLaren Construction has been appointed by O&H Properties to deliver the first phase of a £60 million Foster & Partners-designed development at the corner of New Bond Street and Grafton Street in London’s West End.

The seven-storey, 5,400 square metre prime retail and office scheme will feature ret

29/01/2025

GMI Construction Group has been awarded a contract to develop three high-specification warehouse units totalling over 175,000 square feet at Precedent Drive, Milton Keynes.

The £20 million project, commissioned by DV5 Last Mile Developments (UK) Ltd, a joint venture between Coltham and Delancey Re

29/01/2025

Plans for 106 sustainable new homes in Southville, a neighbourhood in South Bristol, have been approved as the city seeks to increase housing delivery to address growing demand.

Top 10 award-winning housebuilder The Hill Group will create a £60 million development on Raleigh Road, on land that was

29/01/2025

Bouygues UK has reached a major milestone in the fourth phase of the Hallsville Quarter regeneration project in Canning Town, London.

The project, part of the £3.7 billion Canning Town and Custom House Regeneration Programme, recently held a topping out ceremony, marking the completion of the 11-s

29/01/2025

Willmott Dixon Interiors is carrying out a significant upgrade to the roof of the National Maritime Museum in Greenwich, one of London's most iconic cultural landmarks.

As part of the £12 million project, the company is installing over 23,000 square feet of sun-protected glazing above the museum’s

29/01/2025

Equans has been appointed by Babergh and Mid Suffolk District Councils to carry out crucial decarbonisation work across the councils' housing stock, using funding secured through the Social Housing Decarbonisation Fund (SHDF).

The councils used the South East Consortium's Zero Carbon Framework to s

29/01/2025

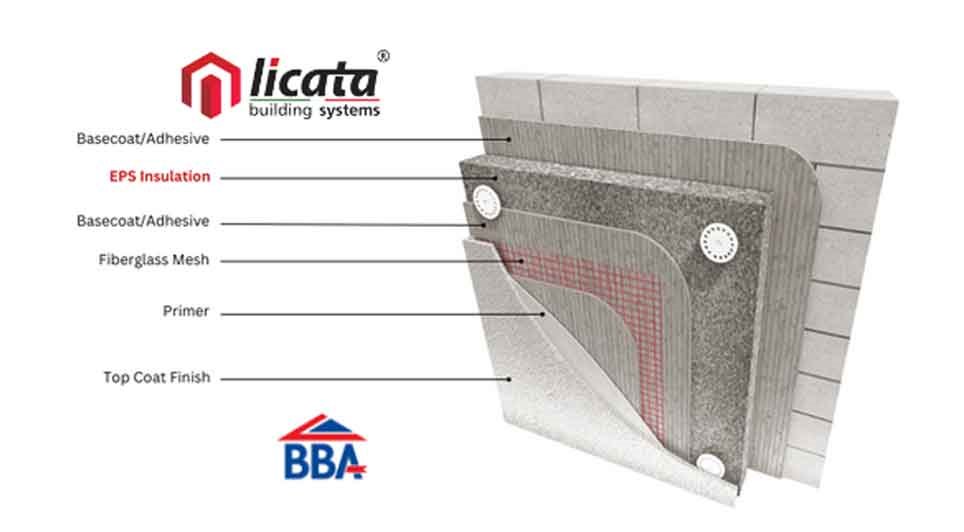

In the world of construction, the quest for energy efficiency and sustainability is ever-evolving. Among the array of solutions available, EPS (Expanded Polystyrene) insulation stands out as a versatile and effective option for enhancing the thermal performance of buildings, particularly when used f

29/01/2025

BCP Council has completed significant coastal protection works at Hamworthy Park, ensuring its resilience against erosion for the next 20 years.

A 200-metre stretch of sea wall along the eastern promenade has been reinforced using low-carbon concrete, while new steps have been constructed to improv

29/01/2025

Geo-environmental consultancy and remediation contractor, The LK Group, has strengthened its team with a trio of recruits.

The multidisciplinary company's latest raft of hires comprises a new director, associate director and remediation manager.

The geo-environmental specialist, headquartered i

UK

UK Ireland

Ireland Scotland

Scotland London

London